Additive Support Structures: Why They Matter and How to Design for Them

Published on April 5, 2022

Additive manufacturing has ushered in a new era of manufacturing possibilities. 3D printing technology enables us to create previously ‘unmakeable’ parts, featuring complex dimensions and angles, with unprecedented speed and precision. However, the nature of the additive manufacturing process, in which material is added layer by layer, often means that parts require support to manage internal pressure–essentially, the force of gravity–during the print. Without that support, additive layers can’t be held up by the material around them and collapse, causing the print to fail. To address this challenge, we must sometimes design support structures into our 3D printed parts.

To ensure you maximize the potential of your 3D printed part for speed, quality, and cost, it’s important to understand support structures and how they should be integrated into your additive manufacturing project.

What are Support Structures in 3D Printing?

Support structures hold up elements of a 3D printed part which have no supporting material during manufacture. Not all 3D printing processes require support structures: while the Stratasys Fused Deposition Modeling (FDM), Carbon Digital Light Synthesis™ (DLS), and Stereolithography (SLA) processes often require supports, HP Multi Jet Fusion, which is a powder bed printing process, does not.

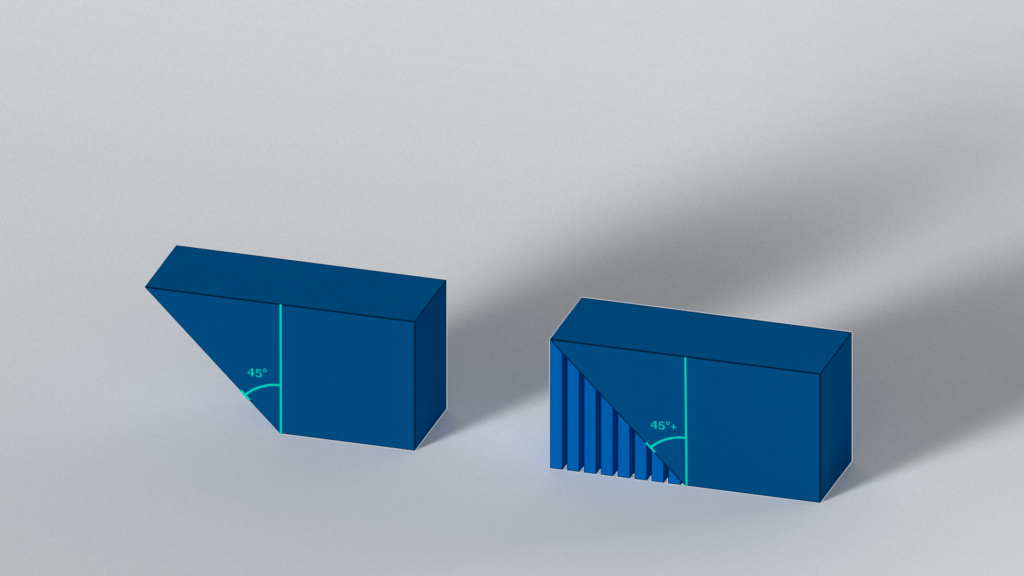

In the Stratasys Fused Deposition Modeling (FDM) additive manufacturing process, for example, layers of heated extruded material are built up from a print bed by adhesion to the material layers below them and may overhang those lower layers in order to create an angled surface. When that angle exceeds 45° the overhanging element generally requires support or the weight of the unsupported material will cause the element to collapse and the print to fail.

Right: If the overhang is greater than 45° taken from the vertical, supports are generally needed

Where supports are required, they must be integrated into the part design and printed into the part when it is produced. Of course, this means accounting for the extra time and material that will be required during the 3D printing process and the subsequent post-process removal of the support structures.

Exceptions: Not all additive manufacturing methods require support structures. While 3D printing technologies such as fused deposition modeling (FDM) print parts by adding layers of material to a print bed, others, such as HP Multi Jet Fusion (MJF) print parts from a powder bed. Since the layers of powder are self-supporting, HP MJF part designs do not need to incorporate support structures.

What Types of Support Structures are Available?

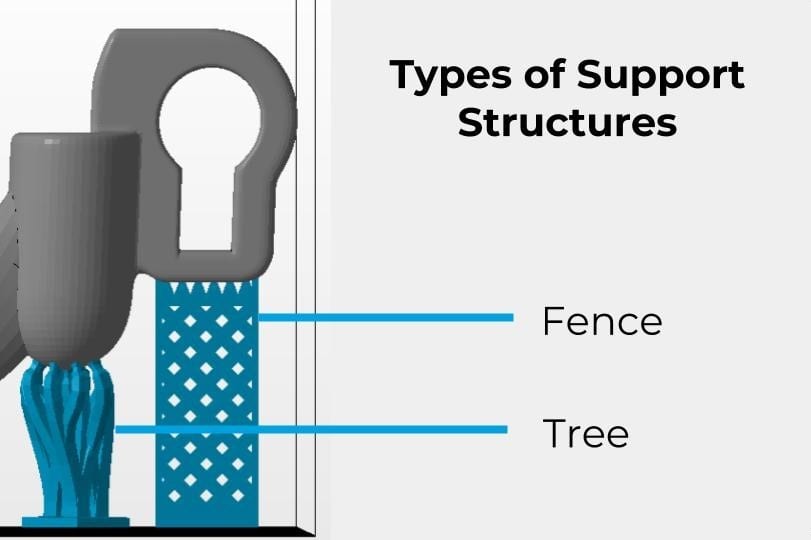

Support structures for 3D printed parts vary in design and type but can be broadly organized into two categories: ‘trees’ and ‘fences’.

- Tree supports: Resembling branches or trunks, tree supports may enclose a part and fit neatly to angled surfaces for ease of removal. Tree supports can be designed, applied and tested quickly as part of a 3D printing project, enabling rapid iteration. Their branch-like structure means they can reach out over distances to support specific areas.

- Fence supports: Resembling walls, and with a variety of mounting points, fence supports are printed perpendicular to a part’s surface often with a lattice structure. Fence supports are more durable and easier to remove than tree supports, and are typically a better choice for cosmetic pieces or high volume production.

When Should I Use Additive Manufacturing Support Structures?

The ‘45° rule’ suggests that 3D printed overhangs of 45° and greater will require support, while those under 45° will not.

However The 45° rule should be considered a general rule of thumb and the need for support structures will vary depending on the complexity of part design and on the material being used. In some cases, bridging may offer an alternative to support structures: bridging is a technique in which heated additive material is stretched across a short distance (usually less than 5mm) without compromising the integrity of the part.

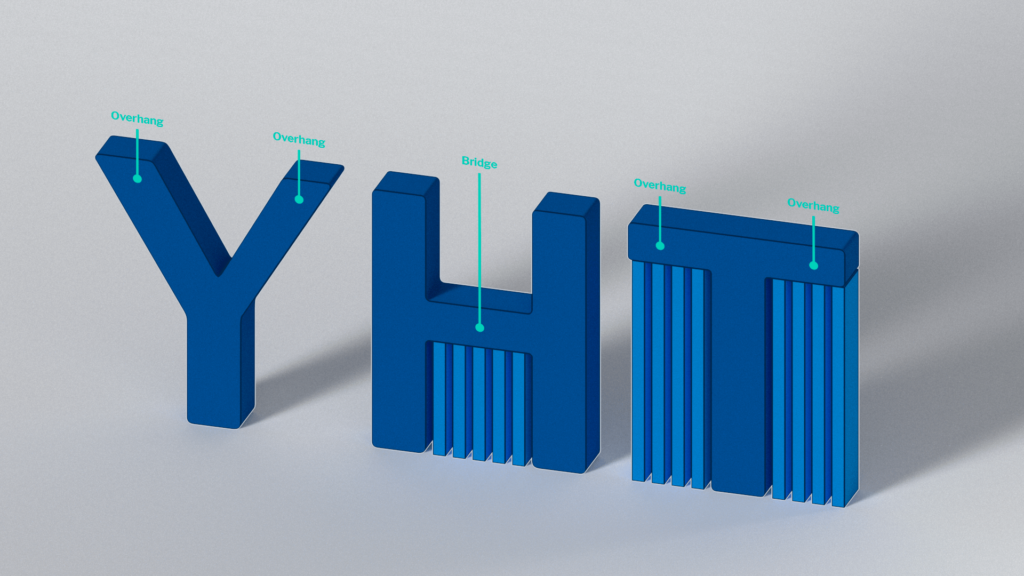

The ‘YHT’ principle: When conceived as 3D printed models, standing upright, the letters Y, H, and T are useful for illustrating the necessity for additive manufacturing support structures.

- The letter Y: Two arms extend from the letter Y at 45° – the angle of their overhang does not necessitate support structures. The further the overhang angle exceeds 45°, the more likely it is that support structures will be needed.

- The letter H: If the two vertical elements of the letter H are within 5 mm of each other, it may be possible to 3D print the horizontal element of the H with a bridge. If the vertical elements are further than 5mm apart, the horizontal element may require support structures.

- The letter T: The two arms of the letter T extend from the vertical element at 90° and will require support structures.

Beyond the angle of an overhang, other factors may affect the need for support structures. These include the quality of the 3D printer and the speed at which it prints: slower printers, for example, may increase the need for support structures.

Support Structures: Manufacturing Challenges

Support structures are a necessity in many additive builds but it’s important to remember that they can significantly affect the cost of a part in volume production — not to mention the amount of waste material that the project ultimately produces. Care should also be taken when removing support structures since they may damage or mark the finished part as they are detached.

With those factors in mind, 3D printed parts should ideally be designed to minimize or eliminate the need for support structures and, where possible, design for additive manufacturing (DFAM) principles should be applied in order to optimize parts for quality, cost, and production time. The following strategies may help to reduce the need for support structures:

Orientation: The orientation of parts on the print bed may affect the need for support structures. Overhangs, for example, may be eliminated by rotating a part onto its back or side. In the examples above, laying each of the 3D model letters Y, H, and T on their backs would completely eliminate any overhanging elements along with the need for support structures or bridges.

Part geometry: Where possible, remove overhangs from your design – or reduce their angle to less than 45°. Obviously, functional requirements may make the total elimination of overhangs impossible but you may be able to introduce alternative design elements such as chamfers, gussets, and radii to make the part’s geometry more self supporting.

Part separation: 3D printing technology enables the production of complex single parts, but if the amount of support those parts needs reduces their quality or cost-effectiveness it may be worth splitting the part into smaller components which can be assembled later. Spherical parts, for example, require substantial support but by splitting them in half, and creating a large flat surface, it’s possible to eliminate the need for supports completely.

Support density: The pressures exerted on support structures will dictate how strong they need to be and how much material is required to print them. To ensure a successful and cost-effective print, ensure your support structures are dense enough to support the size of the overhanging element. Bear in mind that the denser the support structure, the more difficult it may be to remove post-print.

Dissolvable supports: Some 3D printing technology may be able to print support structures in a separate dissolvable material, via a secondary print nozzle. These support structures can be submerged in water or chemicals, post-print, and dissolved to leave an intact part. Dissolvable supports reduce the potential for damage to the finished part during the support structure removal process. Most FDM additive materials have dissolvable supports, DLS and SLA materials do not. The HP MJF process does not require supports at all.

Getting Started

Support structures will continue to play an integral role in most additive manufacturing projects.

While the goal is always to reduce or eliminate the need for support structures, our engineers aim to optimize your part for functionality and cost. If you’d like to know more about how we can make your additive manufacturing project possible, contact the SyBridge team today.