Precision.

Partnership.

Performance.

At SyBridge Technologies, we don’t just build injection molding

tooling—we engineer the foundation of your product’s success.

#2

moldmaker in

North America

50+

years of

experience

17

global

locations

Your Full-Lifecycle Tooling Partner

From concept to high-volume production and ongoing maintenance, SyBridge supports your tooling needs every step of the way. Our proven turnkey process combined with our custom approach ensures your molds perform reliably and stand the test of time.

Explore Injection Mold Tooling

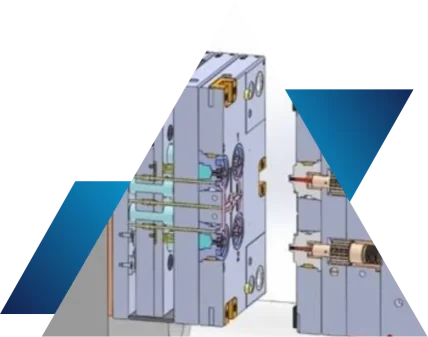

Design & Engineering

Expert tooling design that combines innovation, efficiency, and manufacturability—ensuring your molds are production-ready, cost-effective, and reliable from the first cut of steel.

Design for Manufacturability

Tool Concept

Simulation Analysis

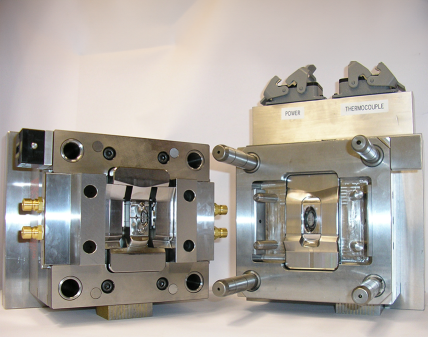

Pre-Production Tooling

Prototype and pre-production molds built for fast iteration, risk reduction, and seamless transition to high-volume production.

Rapid & Prototype Tooling

Pilot, Unit & Pre-Production Tooling

Production Tooling Readiness

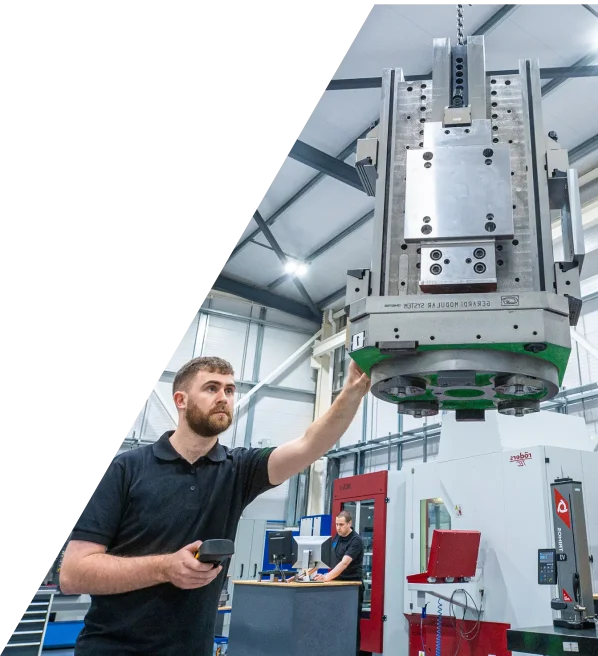

Production Tooling

High-performance production molds engineered for consistent quality, uptime, and efficiency—even in complex, multi-cavity applications.

High Cavitation and Precision (+/- 0.0002”)

Small to Large Format Tooling

Turnkey Solutions

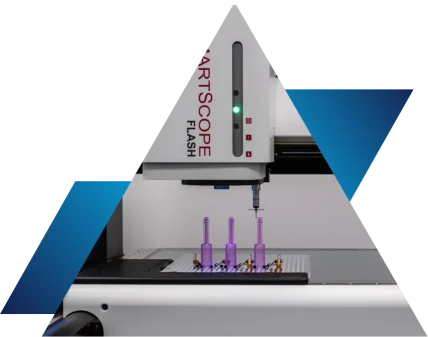

Tools & Part Validation

Turnkey validation services to ensure every mold and part meets strict quality standards, with repeatable, production-ready results.

Mold Final Acceptance Tests (MFAT)

CMM, OGP, Smart Scope Capabilities

In-house IQ / OQ / PQ Validation

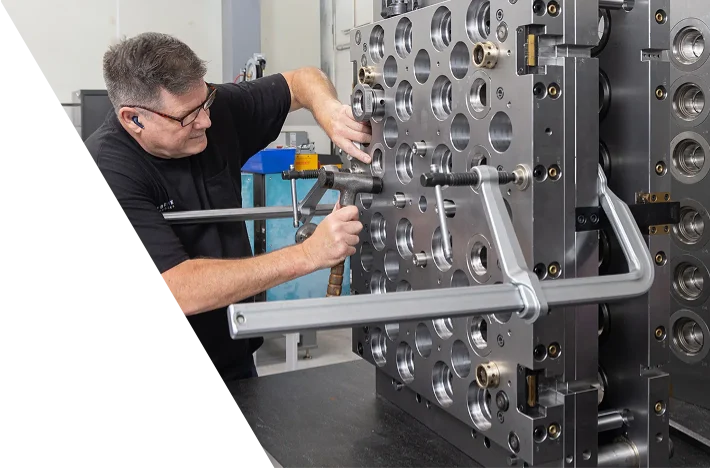

Post-Production Support

Comprehensive maintenance, repair, and refurbishment to keep your molds performing like new, with rapid response and global support.

Replacement Components/Spares

Repairs

Rebuilds

Our Core Markets

We partner with leading OEMs and contract manufacturers across key industries, delivering high-performance tooling and manufacturing solutions that allow you to bring your products to market, faster.

Explore Markets Served

Engineered for the most demanding applications, from drug delivery systems and diagnostics to cardiovascular devices and medical consumables.

From thin-wall containers to complex dispensing systems, we provide the expertise and end-to-end support to accelerate time to market and exceed consumer expectations.

Supporting high-volume programs with engineering precision and supply chain agility for personal care, writing instruments, and home appliances.

Enabling complex parts and programs across interiors, exteriors, and structural systems for automotive, powersports, aerospace, and beyond.

Delivering durable solutions for material handling, storage, construction components, power tools, and animal care systems.

The SyBridge Advantage

Full Lifecycle Capabilities

No need to manage multiple suppliers—we provide seamless support from initial concept through tooling, molding, and preventative maintenance.

Global Scale, Local Support

Wherever you operate, we are nearby. With 17 strategic locations worldwide, you receive immediate, personal access locally—plus the power and scale of our entire global network.

Proven Expertise and

Execution

We’ve been building molds for 50+ years, and we understand what it takes. Our timelines are commitments, ensuring you launch on schedule and with confidence.

Flexible, Customized

Solutions

We don’t believe in one-size-fits-all. Our team partners with you, listening closely to tailor every aspect—from design through final validation—to deliver your precise solution.