A Guide to Common Thermoplastics

Published on August 4, 2020

Originally published on fastradius.com on August 4, 2020

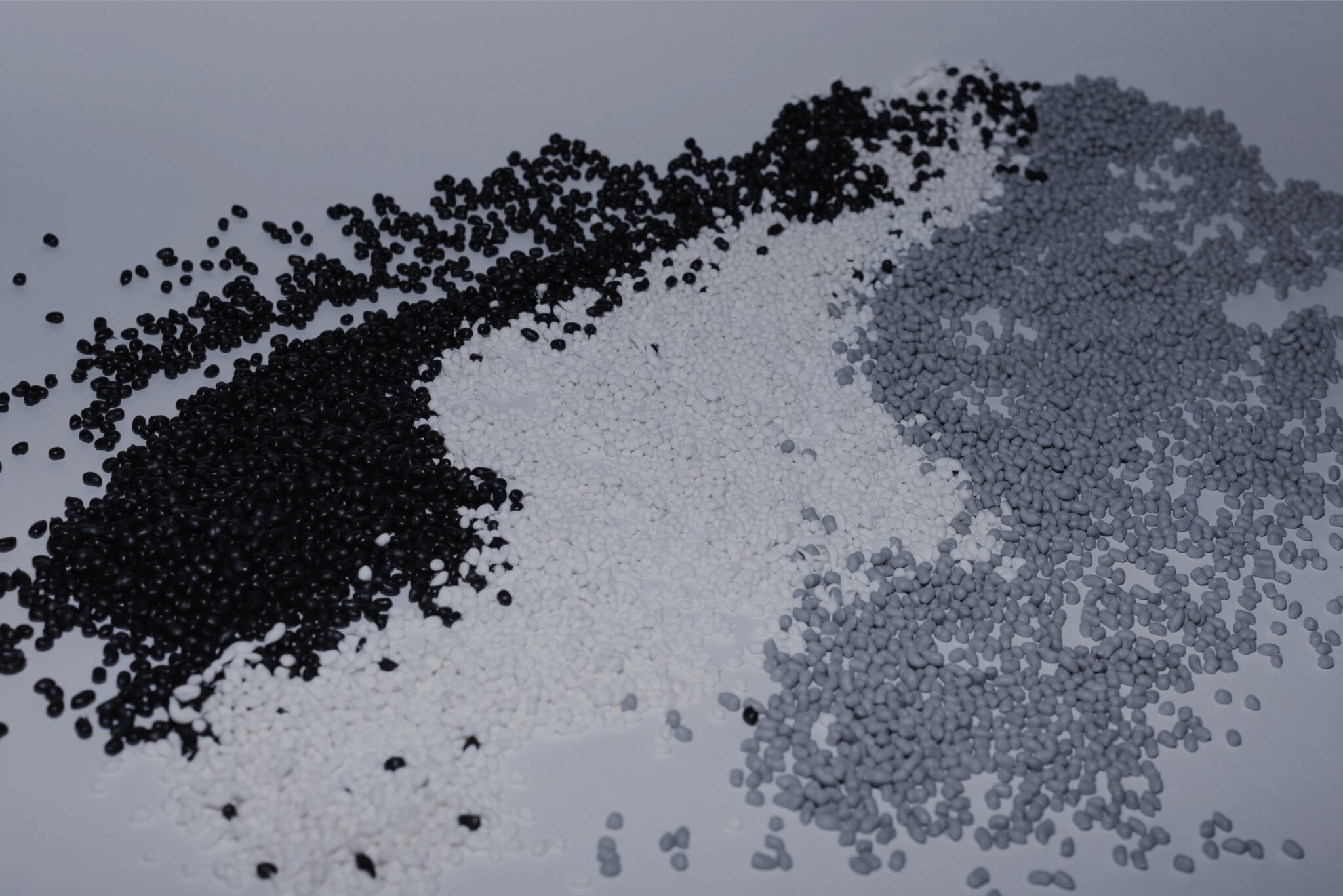

Thermoplastics are plastic polymers with low melting points that become molten when heated, solid when cooled, and can be remolded or remelted after the curing process. They’re strong, flexible, and easy to use since post-processing is often minimal or not required.

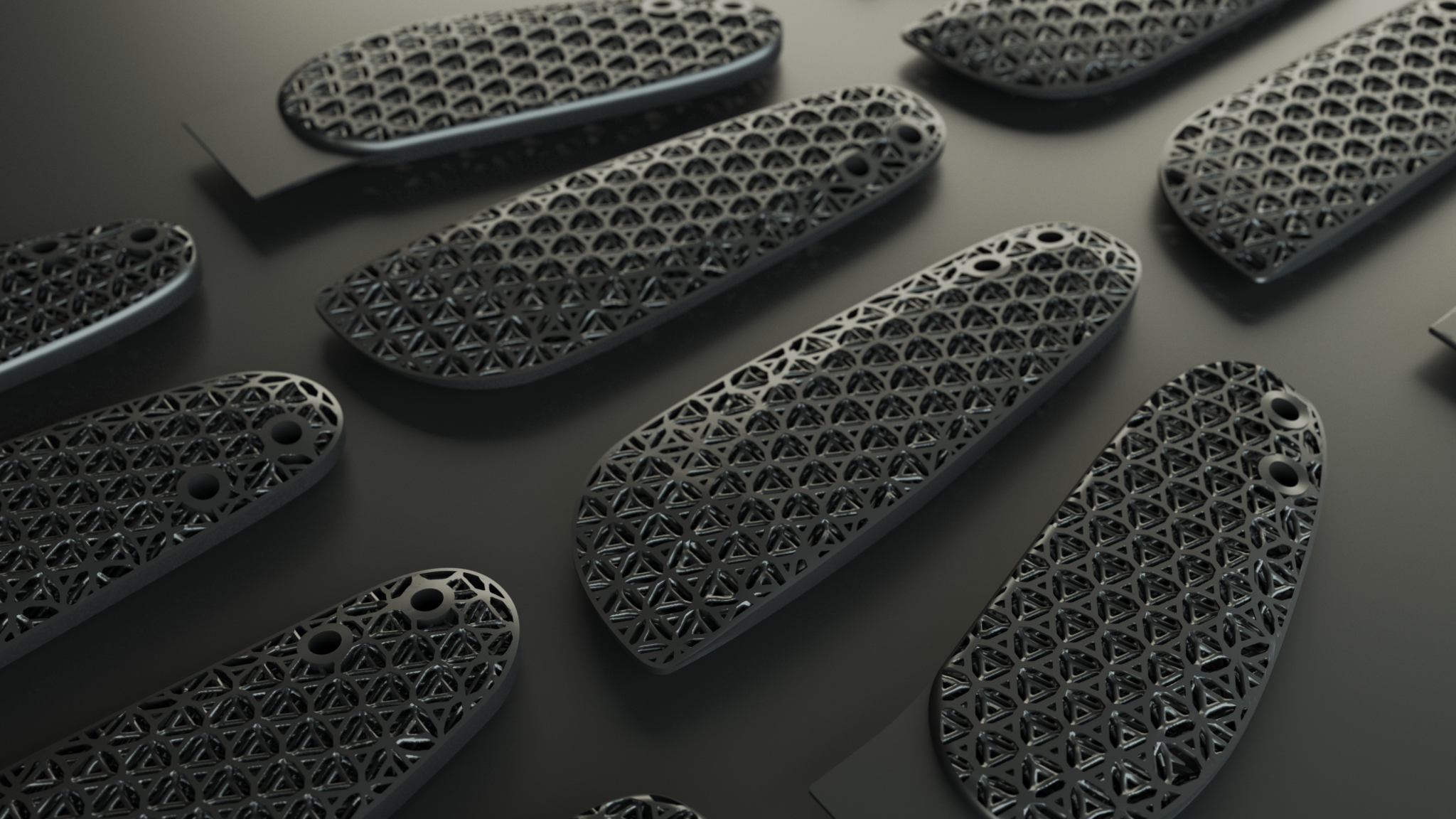

What’s more, thermoplastics are considered some of the most eco-friendly and non-toxic materials on the market today. They’re ideal for injection molding, cost-effectively manufacturing parts with complex geometries, and producing repeatable parts in large volumes. Thermoplastics can be used to create a wide range of common household products, from mechanical parts to children’s toys.

Engineers and product designers should consider using thermoplastics for injection-molded parts, but there are many varieties to choose from. Here’s a guide to the most common thermoplastics, plus tips for product teams on choosing the best type for their next project.

A breakdown of common thermoplastics

Thermoplastics can be broken down into two broad categories — amorphous resins and semicrystalline resins. Amorphous resins are typically brittle, but they’re very precise and have good dimensional stability. These thermoplastics are commonly found in plastic utensils, foam cups, and plastic plates.

Semicrystalline resins are more flexible and chemical resistant than amorphous resins, but can be challenging to work with. However, this material works well for applications involving continuous wear, structural loads, and friction.

Within the categories of amorphous and semi-crystalline resins, thermoplastics can be broken down further by their performance grade. Thermoplastics can be classified as high-performance or specialty-, engineering-, or commodity-grade. Performance grade increases in tandem with the price. Here are six examples of the most common thermoplastics, along with their classifications.

Polyetherimide (PEI)

PEI is a high-performance amorphous resin. It’s strong, chemical-resistant, and able to withstand temperatures upwards of 217°C. Amorphous resins tend to crack when they come into contact with certain fats and oils, but PEI stands out because it’s tough enough to resist such cracking. PEI is used to make circuit boards, eyeglasses, and sterilization equipment, but it’s most frequently used in aerospace applications.

Polycarbonate (PC)

PC is an engineering-grade amorphous resin. This naturally transparent material is heat-resistant, flexible, and a good electrical insulator. It’s also stronger and more rigid than nylon. Common applications include electrical components, lenses, medical devices, and single-use food containers or water bottles. Polycarbonate isn’t considered food-safe for reusable containers.

Polystyrene (PS)

Polystyrene is a commodity-grade amorphous resin. It’s transparent like polycarbonate, but very low in strength and heat resistance. As such, its use-cases are limited to simple products like packing peanuts, foam plates, and cutlery.

Polyetheretherketone (PEEK)

PEEK is a high-performance semi crystalline resin, and one of the toughest thermoplastics on the market — it is resistant to high temperatures, chemicals, corrosion, and biodegradation. PEEK’s mechanical properties make it an ideal choice for bearings, medical implants, piston parts, and a wide variety of applications in the aerospace, automotive, and chemical industries.

Nylon

Nylon is an engineering-grade semi crystalline resin. It is highly stable, versatile, and resistant to many external factors like abrasion and impact. Nylon also promises low shrinkage and warp. Its applications are wide-ranging. It is silky enough to be used in women’s stockings and other apparel, resistant enough to be used in industrial bearings, and safe enough to be used in medical devices.

Polypropylene (PP)

Polypropylene, a thermoplastic beloved by engineers, is a commodity-grade semi crystalline resin. PP is strong and highly resistant to stress, impact, corrosion, and fatigue while remaining extremely flexible. Engineers enjoy working with PP because it offers them many (if not all) of the chemical and mechanical properties they require for their respective use-cases at a very low price point. Common applications include household goods, automotive parts, reusable containers, and even carpeting.

Key considerations for choosing a thermoplastic

These six common thermoplastics are only the beginning. How can engineers and product designers possibly sift through all of the available options and make the right choice?

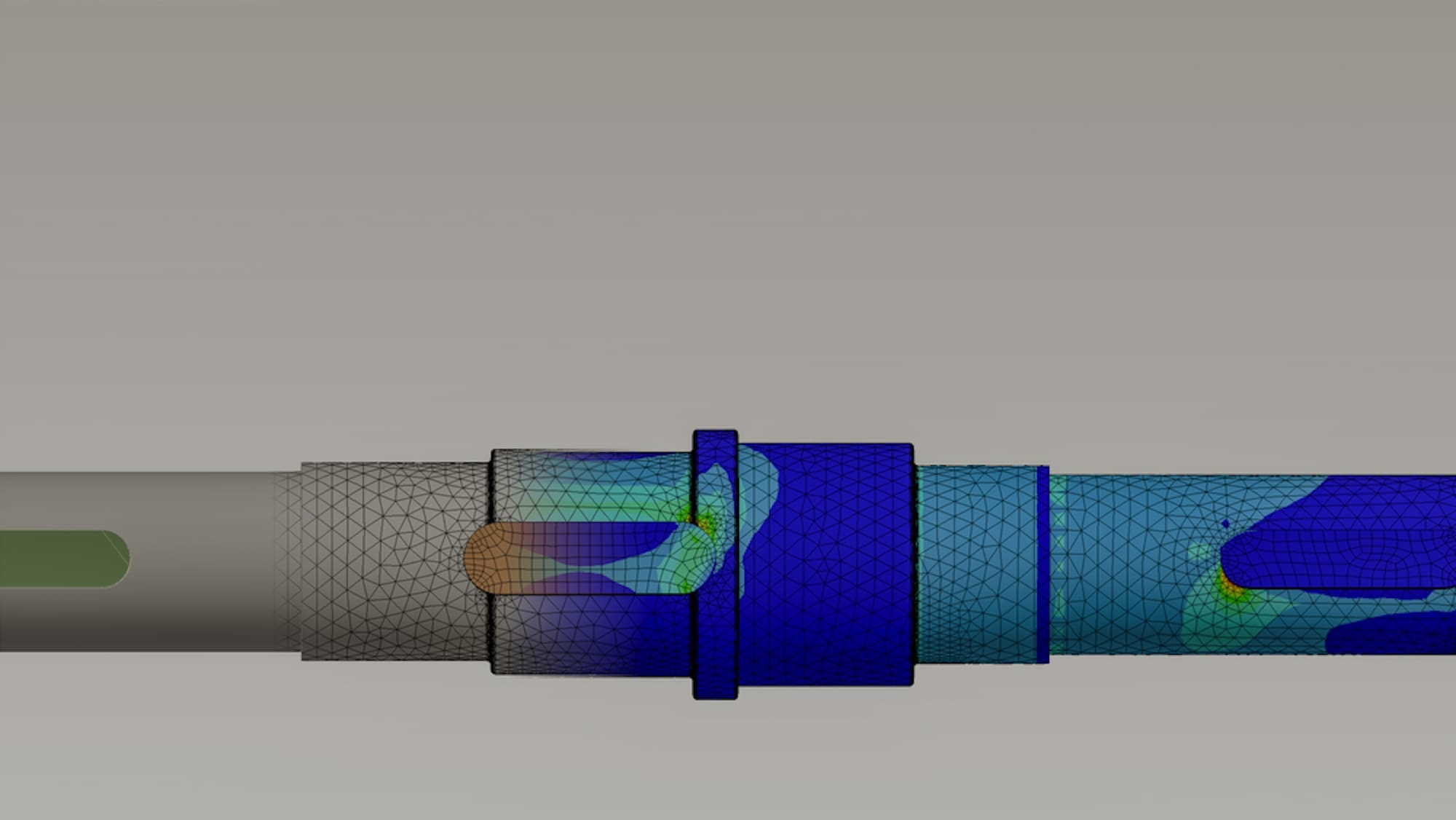

The best way to choose a thermoplastic is to start by considering the part’s engineering requirements. The objective is to pick a material that will offer all of the properties the part needs and to do so as cost-effectively as possible. As such, it’s critical to begin by outlining key engineering requirements, which will serve as useful guideposts in evaluating material options. With these guidelines in mind, seek the best compromise between desired mechanical properties and cost.

Many manufacturers use material selection charts to simplify the evaluation process. By pinpointing the materials that lie in the crossover point between two desired variables — say, density and cost — product teams narrow the pool of viable candidates and gain clarity around which materials are likely to prove most effective. Highlight the important engineering requirements that matter, nail down a price range, and select a material that is most cost-effective for the performance needed.

Optimize the product lifecycle with expert advisory

Handy material selection charts like those pictured above are helpful for whittling down a large pool of materials to just a few, but there’s no substitute for expert advice. To select the best material for a given part, product teams would do well to consult an expert manufacturing partner like Sybridge Technologies.

When you partner with SyBridge, you gain access to a dedicated team of experts who know all there is to know about manufacturing innovation. From choosing the right thermoplastic for your project to accelerating time-to-market, our team of dedicated engineers, technologists, designers, and advisors can help optimize the production process and the entire lifecycle of your product. Contact us today to get started.