Top 3 Things Learned About Mechanical Properties of Additively-Manufactured Lattice Structures

Published on November 27, 2020

A recent study conducted by a team of researchers at the University of Illinois Urbana-Champaign shows that the success of an additively manufactured part is reliant on the success of the build.

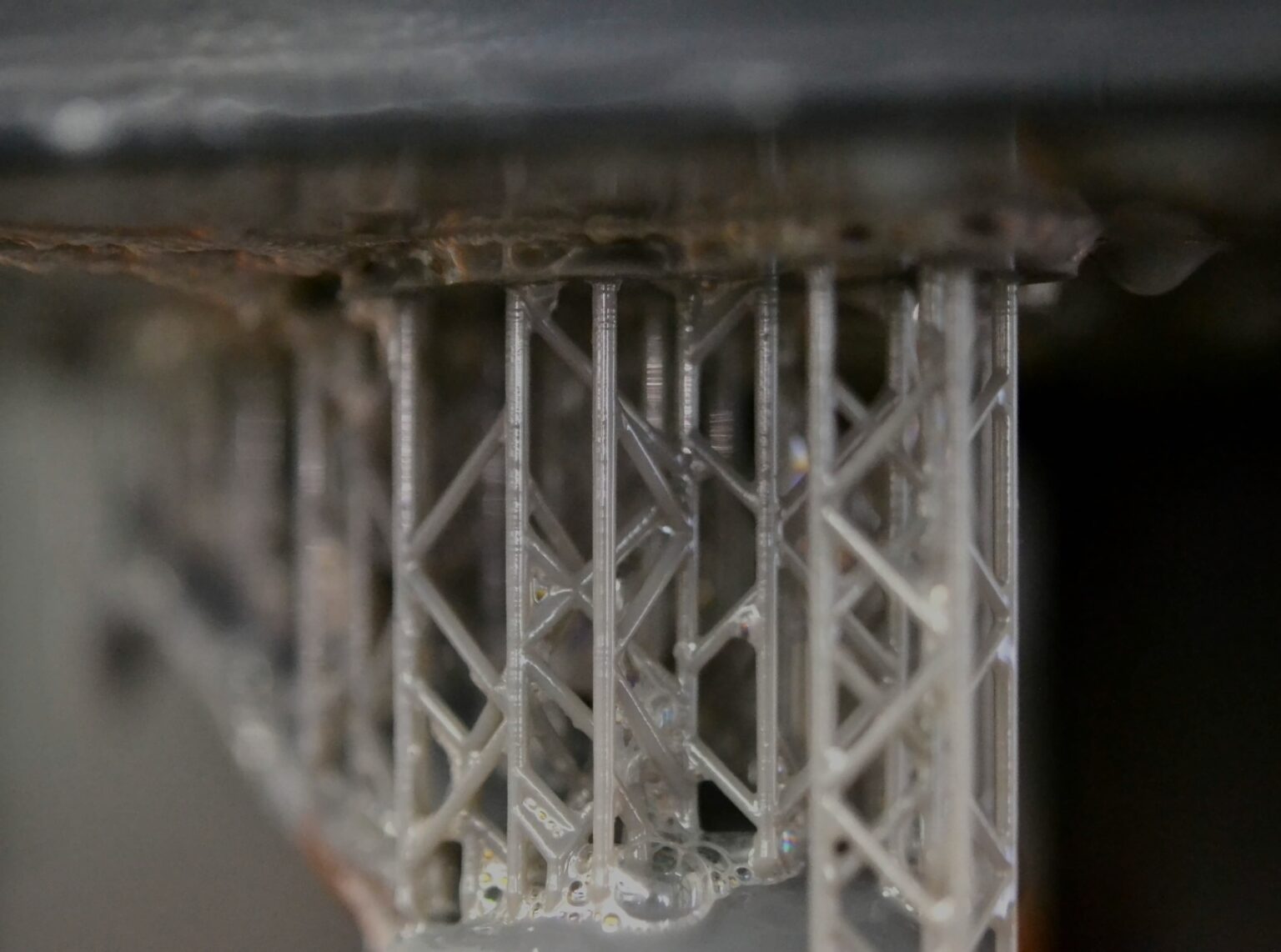

With recent advancements, additive manufacturing (AM) has enabled rapid production speeds, high spatial resolution, and strong materials – but the design freedom it offers for architectured lattice materials can be seen as one of its most attractive benefits.

Understanding the mechanical properties of lattice structures plays a key role in unlocking the potential of AM. As the study shows, 3D printing isn’t as easy as plugging in a machine and hitting “print.” Parts made with lattice design and additive technology are just as good, if not sometimes better, than parts made with traditional processes – but it takes additive manufacturing engineering and expertise to ensure scalability and reliability of those parts.

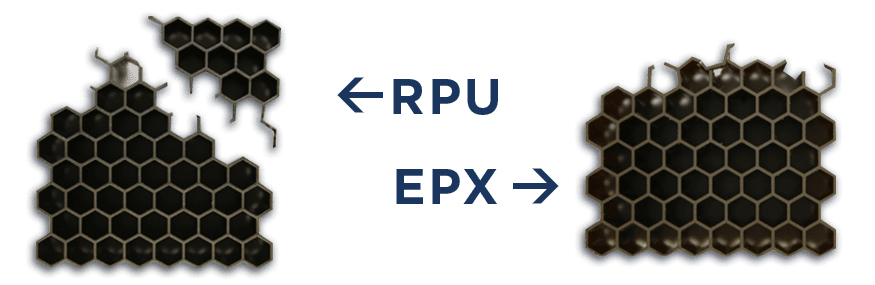

SyBridge collaborated with the University of Illinois to determine whether AM lattice parts could be made repeatedly and at scale. Aimed at understanding the true capabilities of lattice manufacturing, this study involved manufacturing over 50 parts using four different lattice design types and three different materials to test their strength and integrity. SyBridge provided the manufacturing engineering expertise and manufacturing capability to support this research. This is the largest study ever published that tests and validates additively manufactured lattice structures.

The entire study is packed with important data and insights, but there were three main findings for engineers and designers to note. Those findings relate to the accuracy of AM parts, the mechanical behavior of the lattice properties, and the need for failure analysis.

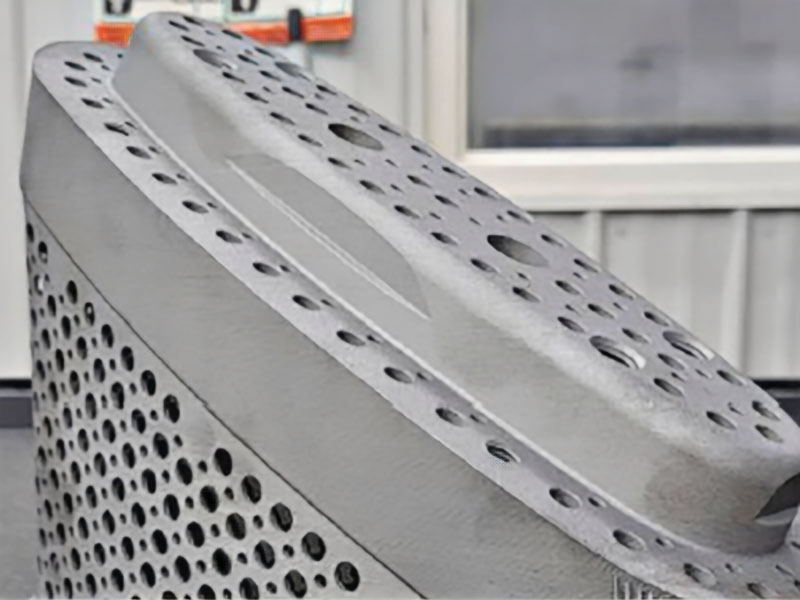

1) Lattice structures made on production grade additive manufacturing equipment are highly accurate.

Each of the 50 parts manufactured had hundreds of individual geometric features. The team used sophisticated scanning technology to measure more than 1,600 features in those parts to ensure their accuracy.

The finding: Measurements of these printed parts showed that their accuracy met industrial standards. This reinforces the idea that additively-manufactured lattices are both repeatable and able to scale for industrial-grade production.

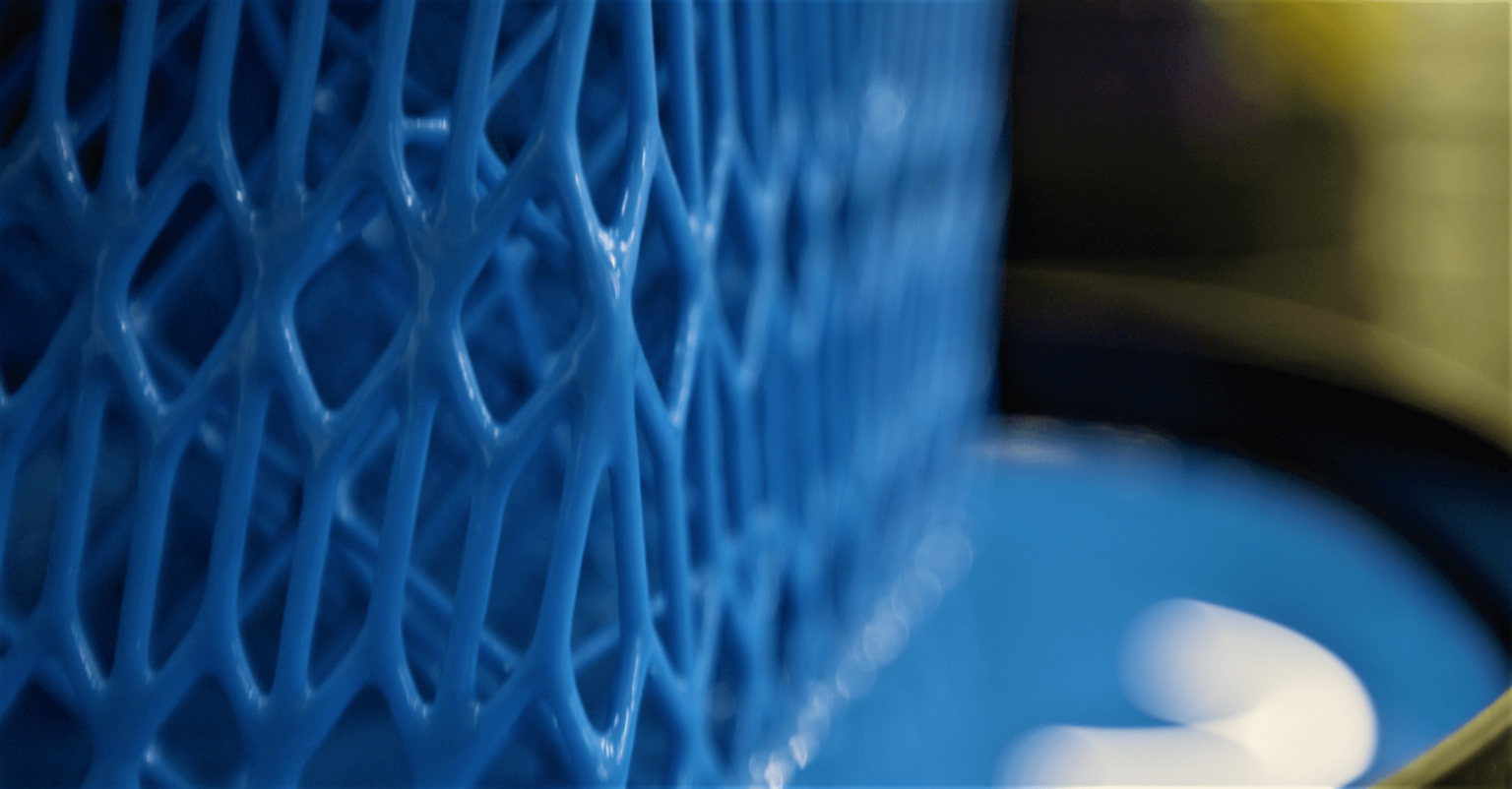

2) Mechanical properties of AM parts behave predictably.

In order to ensure that parts designed using lattices could meet design requirements, mechanical properties were tested and measured, including the stiffness and strength of parts.

The finding: In general, the parts tested behaved in an expected manner based on engineering theory and prediction. In some cases, certain parts were weaker by up to seven percent. By understanding these unique characteristics of the printed parts, designers can tailor part geometries that account for process variables, like part orientation and support.

3) Failure analysis is a critical part of designing for AM.

When particular parts failed, the team was able to analyze how and why the part failed. Different failure mechanisms were found to be at play, and the specific failures depend on the geometry, orientation, and material properties.

The finding: The mechanical strength of a lattice part depends upon the failure mechanism specific to each part. When the failure mechanisms are understood, engineers are able to select lattice designs accordingly.

Understanding the strength of lattice design is the first step to unlocking new opportunities with additive manufacturing. Read our article, “Understanding 3D printed lattices: Performance and design considerations” to start implementing lattice design into your own projects. Contact us today to get started.