Know Your Materials: Polyetheretherketone (PEEK)

Published on June 21, 2021

Originally published on fastradius.com on June 21, 2021

PEEK was first conceived in 1978 — relatively recently by manufacturing standards — as a high-temperature resistant material for cable insulation. Over the past 50 years, PEEK has developed into one of the most widely used materials for high-performance applications.

In fact, PEEK is one of the most commonly manufactured polyaryletherketones (or PAEKs) for large-scale production runs. To make the most out of this versatile and adaptable material, engineers and product teams should familiarize themselves with the properties, characteristics, and limitations of PEEK.

What is PEEK?

PEEK is a polymer created by step-growth polymerization, in which the polymer chain doubles with each polymerization step. This material boasts incredible electrical resistance along with heat resistance, wear resistance, and fatigue resistance. PEEK is also creep-resistant, meaning it will retain its shape in harsh environments and high temperatures, and when placed under mechanical stress. Along with being tough, PEEK is lightweight and easy to manufacture.

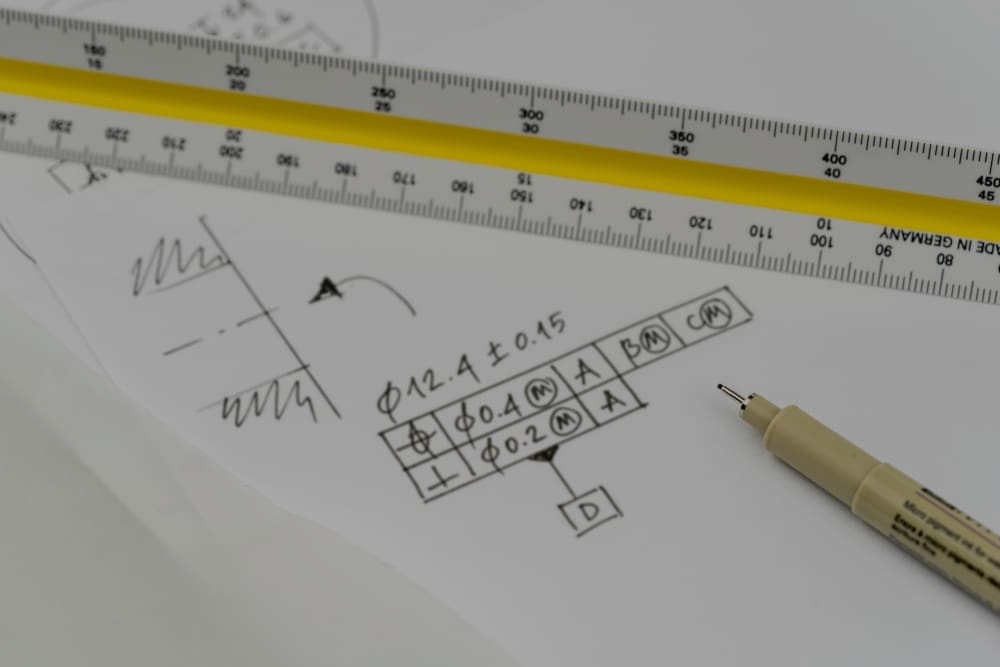

Since PEEK is physically light yet highly resistant to corrosive substances, it is well-suited for a variety of manufacturing methods. PEEK can be processed using injection molding or additive manufacturing, where its high melting point permits faster feeds and speeds. PEEK can also be manufactured via CNC machining. Across manufacturing methods, PEEK offers repeatability and accuracy component-to-component and can produce parts with tight tolerances.

Pure, unfilled PEEK is quite durable on its own, but PEEK is also often reinforced with carbon or glass fibers to become less brittle. Glass-filled PEEK offers more stiffness than unfilled PEEK and is often used in the oil and gas industries to ward off poor reactions to steam, chemicals, and high temperatures.

One disadvantage of glass-filled PEEK is its tendency to wear down mating parts. Carbon-filled PEEK has increased compressive strength, which dramatically lowers its expansion rate and supports better wear-resistance and load-carrying capabilities. Carbon-filled PEEK also has more thermal conductivity, increasing a part’s lifespan and performance.

Properties and Mechanical Specifications of PEEK

PEEK was developed as a high-heat-resistant plastic and only melts at an extremely high temperature. PEEK also releases very low smoke and toxic gas emissions when exposed to fire, reducing hazards when near flame or extreme heat. This makes PEEK an excellent choice for manufacturing methods that require heating and melting, like injection molding.

Some other mechanical specifications for pure, unfilled PEEK include:

- Tensile strength: 14,000 psi

- Tensile modulus: 590,000 psi

- Water absorption: 0.50% over 24 hours

- Melting point: of 343°C (nearly 650°F)

- UL 94 V-0 flammability rating: (0.059″ thickness)

PEEK is also highly chemical-resistant and abrasion-resistant, and can maintain its shape throughout continuous exposure to hot water or steam. PEEK is also biodegradation-resistant and can survive extreme natural conditions, like intense environments and temperatures.

Key Considerations for Manufacturing With PEEK

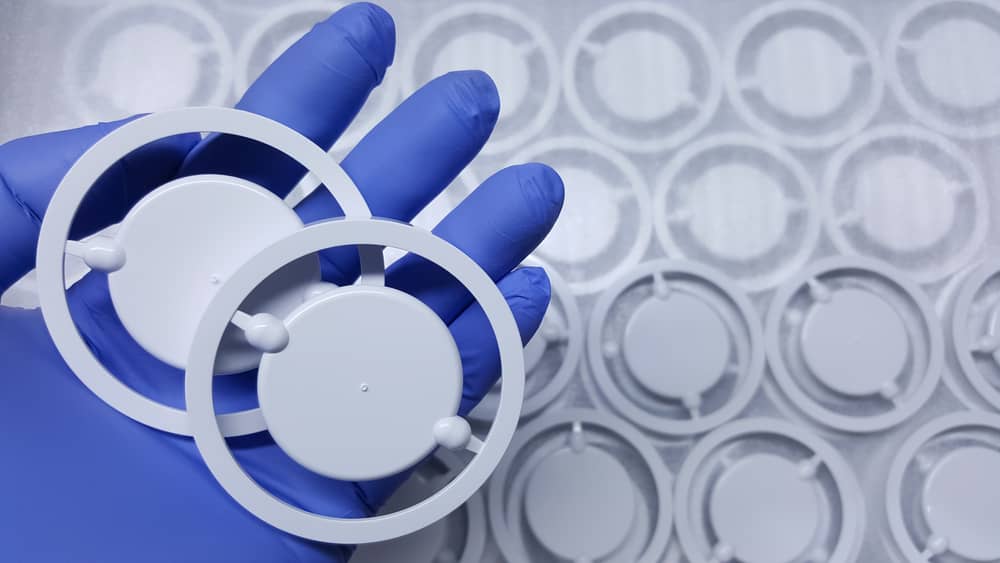

PEEK is a very adaptable material, but there are a few engineering considerations to keep in mind to ensure the best results. For instance, even though PEEK is very heat-resistant, it doesn’t dissipate heat well and must be cooled during machining to prevent breakage or deformation. This can be achieved by using standard liquid coolants, but doing so can affect biocompatibility. In cases where PEEK products require direct human contact, pressurized air is the better alternative for cooling PEEK.

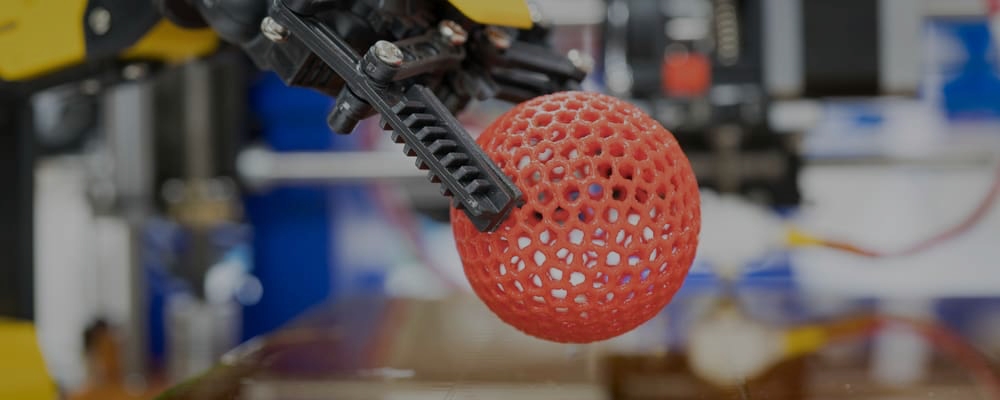

A mold temperature of 160°C to 190°C (320°F to 374°F) is recommended when using PEEK, as this will help minimize warping and yield optimal crystallization. When utilizing PEEK for additive manufacturing, the printing nozzle temperature should be 360°C to 400°C (680°F to 752°F) with a heated bed of 120°C (248°F).

Other considerations include:

- Lower elongation: Since PEEK has lower elongation than other plastics, it can crack if you drill into it deeply. Special handling is often required to minimize heat cracks and other internal stress damage.

- Susceptibility to cracking: Annealing is also required when using PEEK. This process helps reduce the chance of stress surface cracks and deformation, which PEEK is prone to during machining. Depending on how much PEEK will be machined, multiple annealing stages could be necessary.

- Tool choice: Oftentimes, you can machine PEEK with silicon carbide cutting tools. Diamond tools might be required when using carbon-filled PEEK or when trying to achieve tight tolerances. Also, ensure your cutting tools were not previously used on metals to avoid contamination.

Popular PEEK Applications

There are three main industries that utilize PEEK components — the industrial sector, the healthcare sector, and the food and beverage industry.

Industrial Applications

Industrial-grade PEEK is inherently pure and supports high mechanical and chemical stability. This minimizes contamination and maximizes safety efforts for chemical and energy applications, as well as for components in the automotive, aerospace, and electronics industries. PEEK can even outperform metals, such as stainless steel, when it comes to industrial wheels and pumps.

Medical Applications

PEEK can create components for the healthcare industry such as orthopedic devices and spinal fusion devices. PEEK can also be used for dental implants, healing caps, and more when manufactured with biocompatible methods.

Food and Beverage Applications

PEEK was recently approved by the US Food and Drug Administration (FDA) for safe human contact when properly prepared. Now, PEEK is finding its way into the food and beverage industry for use in components like cookware, beverage dispensers and nozzles, and processing applications.

Why Choose PEEK?

PEEK can be melt-processed without creating corrosive gasses, making it extremely safe and effective to use with injection molding and additive manufacturing. PEEK’s high melt point also opens it up to CNC machining possibilities, as fast-moving tools can cut PEEK without causing any melting.

Manufacturing PEEK using any of these methods results in good mechanical performance and consistency between parts. PEEK can also support complex designs and geometries with additive manufacturing — in fact, PEEK offers a significantly higher tensile strength and tensile modulus than polyethersulfone (PES), a primary material competitor.

PEEK is more heat resistant than PES and polyphenylene sulfide (PPS), another material product teams often swap out for PEEK. While PES can be used up to 220ºC and PPS can stand continuous use up to 250ºC, PEEK doesn’t even begin to melt at these temperatures. PEEK offers similar water and chemical resistance to PPS while boasting increased temperature control, resulting in total outperformance across high-heat applications.

Getting Started With PEEK

PEEK is a relatively new polymer that offers incredible heat resistance, electrical resistance, and corrosion resistance. Along with its durability, PEEK is lightweight and incredibly processable, allowing for accurate and consistent production runs even when using tight tolerances. Product teams must perform their own research in order to determine if PEEK is the right material for a particular part, but making these decisions is far simpler with the help of a trusted manufacturer.

At SyBridge, we’re dedicated to helping you reach your manufacturing goals. Our expert manufacturing team has experience with a wide breadth of material types and manufacturing methods. If you think PEEK is the right material for your upcoming project, we’ll guide you through the entire manufacturing process from material selection to launch. Contact us today.