Know Your Materials: Acetal vs. Nylon

Published on June 15, 2021

Previously published on fastradius.com on June 15, 2021

Engineering plastics, a group of plastics that have better mechanical and thermal properties than other plastics, are often used as replacements for traditional engineering materials such as wood, metal, or rubber. Two of the most commonly used engineering plastics are acetal (known by many names like Delrin and POM) and nylon, which both offer low coefficients of friction and excellent durability. These two materials can also be used for many of the same applications, such as bearings, bushing, and high-performance gears.

Since there’s so much overlap between nylon and acetal, it can be difficult to grasp the key differences between the two and choose one over the other. Here’s everything product teams need to know about nylon and acetal, plus how they can determine which is better for their project.

Overview of Nylon Plastic

Like other plastics, nylons are made by distilling hydrocarbon fuels. There are two main processes by which nylons are created — polymerization and polycondensation. Polycondensation involves the reaction of a diamine with dicarboxylic acids and results in the formation of a more biodegradable nylon. Polymerization, on the other hand, involves reacting amine monomers with carboxylic acid.

Nylon’s semi-crystalline structure provides a high level of stiffness, strength, chemical resistance, and heat resistance. For these reasons, nylon is ideal for applications involving friction, such as gears or bearings. However, nylon tends to absorb moisture from its surroundings, which can have a negative impact on a part’s stability and functionality, and it isn’t inherently resistant to UV light. Luckily, the use of preconditioning treatments can mitigate both of these effects and reduce damage.

The numerous types of nylon are all identifiable by number. The three most common types of nylon are Nylon 6, Nylon 66, and Nylon 12, and the physical and chemical properties of nylon will vary by type. Some key mechanical specifications for unreinforced Nylon 6, for example, include:

- Water Absorption: 1.900%, 24 hrs @ 73.4°F (23°C)

- Tensile Strength: 76 MPa

- Flexural Strength: 110 MPa

- Flexural Modulus: 2965 MPa

- Hardness: 116, Rockwell R

- Melting Temperature: 428°F (220°C)

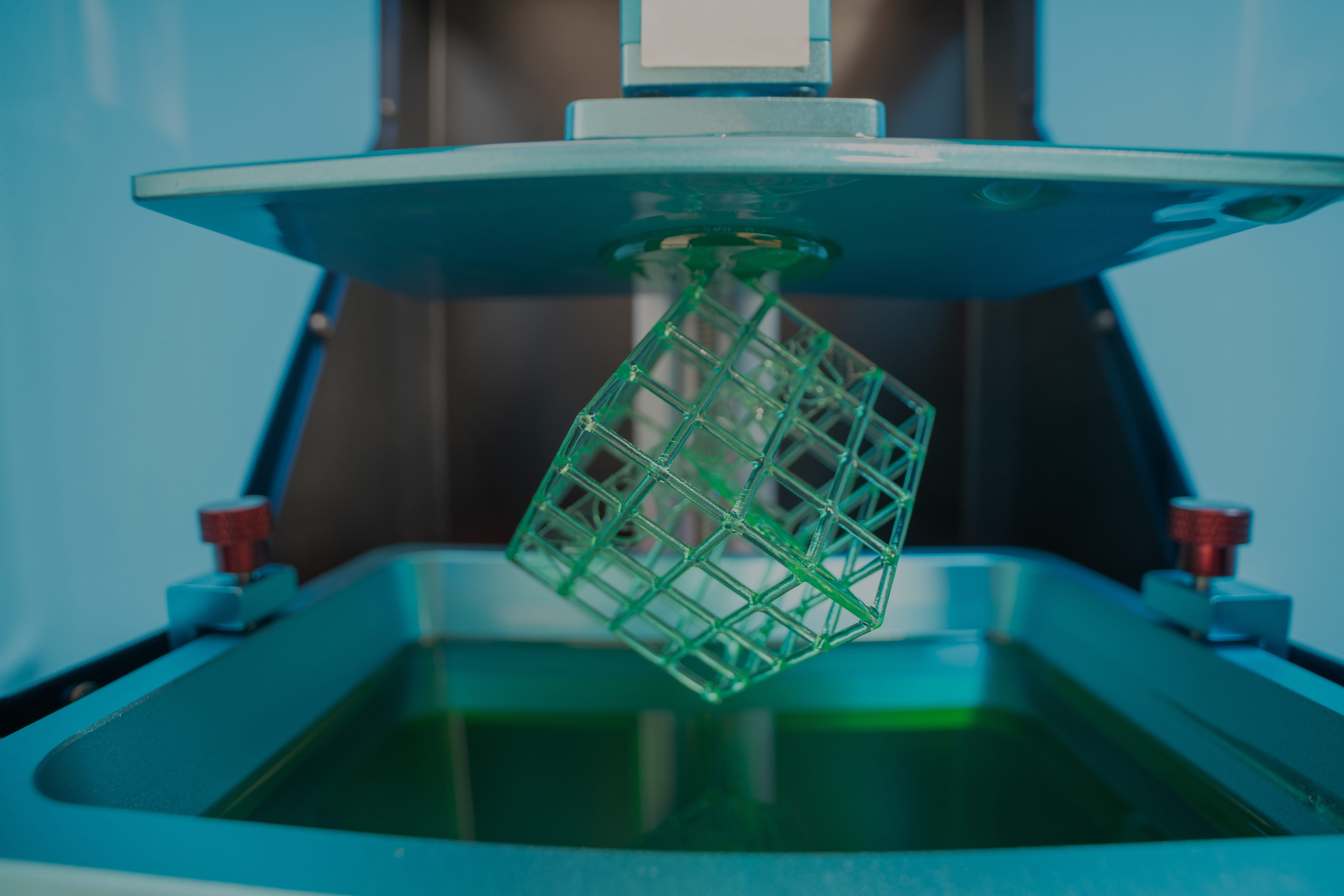

Nylon is highly valued for its strength and versatility, as well as its natural low-friction properties. It can be shaped into filaments, fibers, films, and sheets, and it’s compatible with a range of manufacturing processes, including injection molding, CNC machining, and 3D printing. For these reasons, nylons are often used from prototyping to high volume serial production. Nylons are also used across a variety of industries for a wide range of applications. Nylon film is often used for food packaging, nylon parts frequently replace aluminum components in engines, and nylon is often used for electrical applications like cable ties, insulators, and switch housings.

Overview of Acetal Plastic

There are two main types of acetal — homopolymers and copolymers. Homopolymers and copolymers have different chemical compositions, are used for different applications, and require different manufacturing processes. Homopolymer acetal is produced by reacting aqueous formaldehyde with alcohols to form hemiformal, then distilling this mixture and polymerizing it with catalysts. Acetal copolymer manufacturing is more complex and involves converting formaldehyde to trioxane, which is then distilled and polymerized with catalysts.

Homopolymers tend to be stiffer and harder with a more slippery texture. Copolymers, on the other hand, have better dimensional stability and greater resistance to chemicals. Both types of acetal are favored for applications that require strong resistance to abrasion, water, and chemicals, as well as low friction. Some of these applications include gears, zippers, consumer electronics, plastic furniture, and medical supplies.

Other common applications for acetal include mechanical gears, electrical insulation, housing parts, automotive parts like power windows and door locks, food industry materials like food conveyors, and more. However, unlike nylon, acetal isn’t particularly compatible with 3D printing. For this reason, it’s not used for prototyping to the extent that nylon is.

Acetal plastic material properties vary by type, but its typical mechanical and physical properties include:

Homopolymer Acetal

- Water Absorption: 0.25%, 24 hrs @ 73.4°F (23°C)

- Tensile Strength: 10,000 psi

- Flexural Modulus: 420,000 psi

- Coefficient of friction: 0.20

Copolymer Acetal

- Water Absorption: 0.20%, 24 hrs @ 73.4°F (23°C)

- Tensile Strength: 9,800 psi

- Flexural Modulus: 370,000 psi

- Coefficient of friction: 0.21

Acetal is highly favored for its high strength, low friction properties, and excellent wear properties in both hot and cold environments. What’s more, because it’s easy to machine, it tends to be an excellent material choice for applications that require tight tolerances.

Getting Started with Acetal and Nylon

Nylon and acetal are versatile thermoplastics that are both excellent choices for many projects. However, despite the similarities between the two, they’re not the same material and should not be conflated. Nylon is an abrasion-resistant material that’s particularly compatible with 3D printing. Acetal, on the other hand, is more resistant to moisture and exceptionally compatible with CNC machining. Product teams must always do their due diligence to ensure the plastic they’re choosing for the project is truly the right fit. Luckily, an experienced partner can help make the material selection process a breeze.

When product teams partner with SyBridge, they’re partnering with a team of experienced on-demand manufacturing experts with a strong track record of success bringing products to life. With expertise in both traditional and additive manufacturing methods, our team of designers, engineers, and advisors can guide you through the entire manufacturing process, from material selection to the finished product. Contact us today to get started.