7 Common Injection Molding Defects and How to Avoid Them

Published on January 18, 2024

Injection molding is an efficient production method when high volumes of identical parts are needed. However, it also requires a high degree of technical expertise to master. With so many different variables in play, small, seemingly minor mistakes in early phases of product development can lead to major problems — and even compromise product integrity — down the line.

Defects can reduce the speed and cost-efficiency of the entire product development process, and can potentially shorten product life spans if left unchecked. Injection molding issues and defects can be caused by a host of reasons, including poor design, production process mistakes, quality control failures, and more. As such, it’s important to take a proactive approach to risk mitigation throughout the product development process so as to reduce the chances of potential injection molding defects.

Here are a few of the most common defects that may occur in plastic injection molding — and how product teams can avoid them.

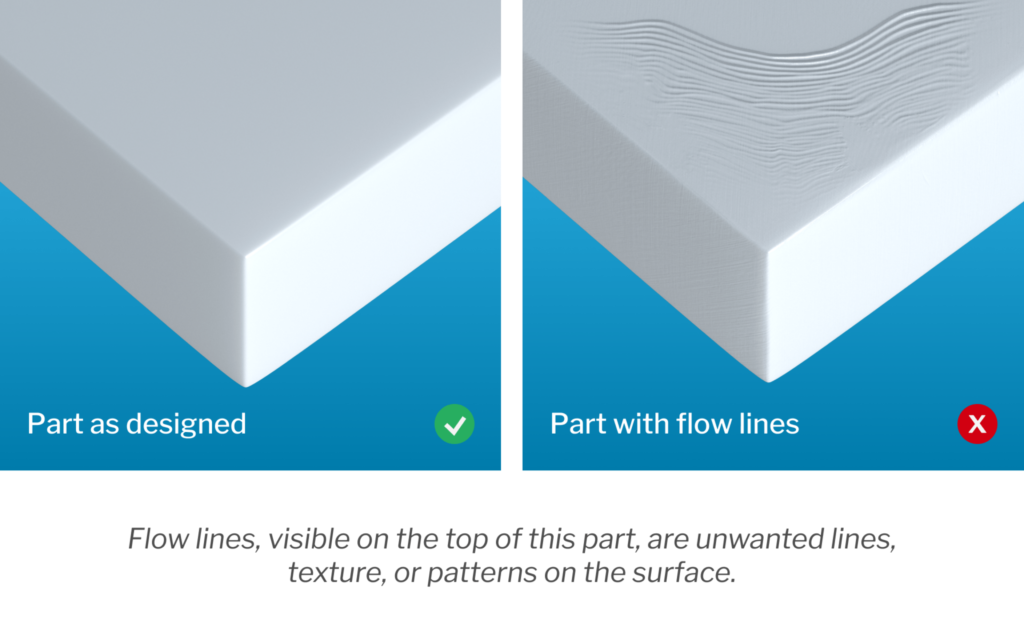

1. Flow Lines

Flow lines are off-color lines, streaks, and other patterns that appear on the surface of a part. These are caused by the shot of molten plastic moving at different speeds throughout the injection mold, which ultimately causes the resin to solidify at different rates. This is often a sign that injection speed and/or pressure are too low.

Flow lines can also appear when the thermoplastic resin moves through parts of the mold with different wall thicknesses — which is why maintaining consistent wall thickness or ensuring that chamfers and fillets are an appropriate length is critical. Placing the gate in a thin-walled section of the tool cavity can further help to reduce flow lines.

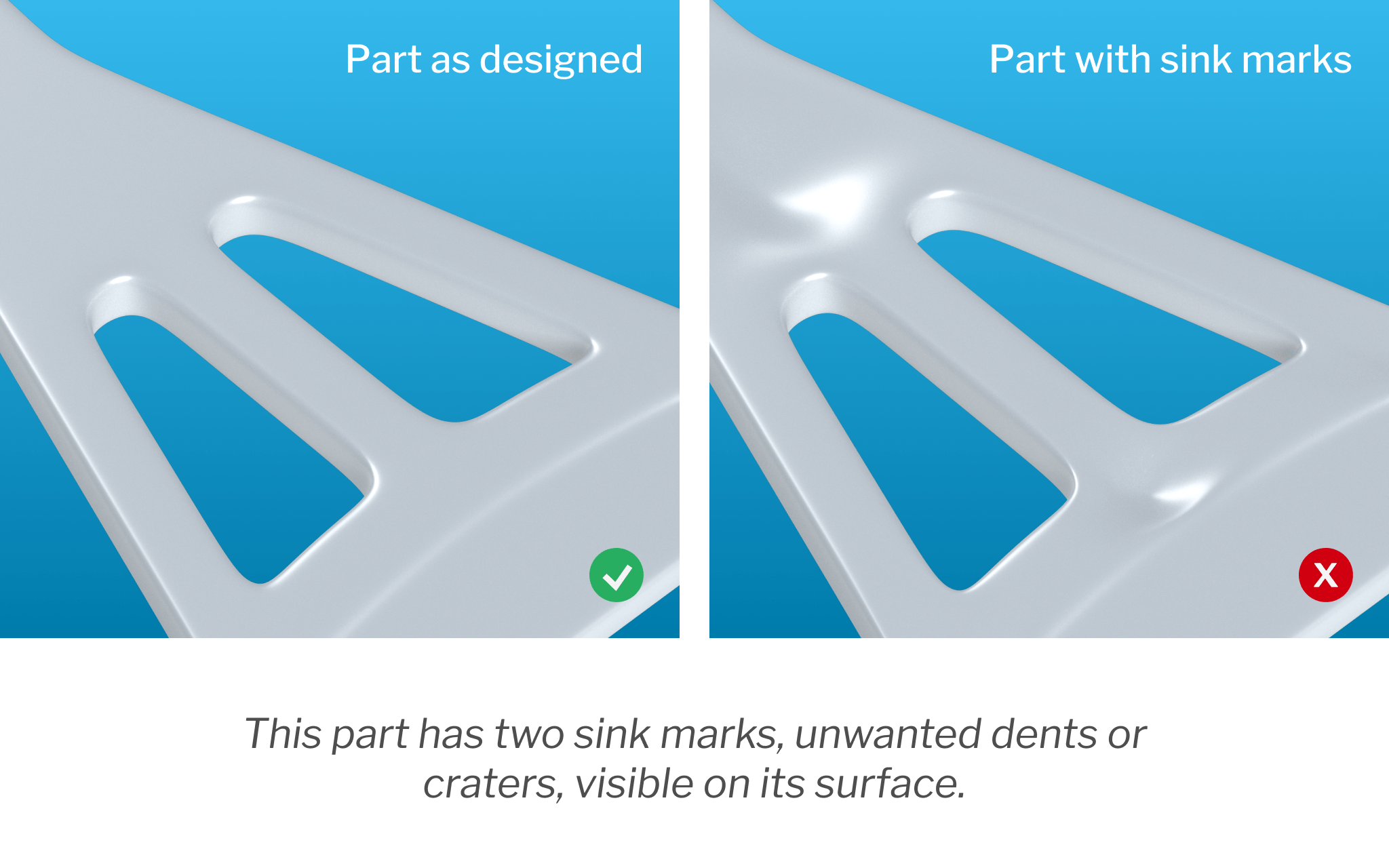

2. Sink Marks

Sink marks appear as depressions, dents, or craters in thick sections of a part. Thicker sections take longer to cool, which can have the often unanticipated side effect of the inner portions of the part shrinking and contracting at a much different rate than the outer sections.

Though most often an indicator that the plastic needs more time inside the mold to properly cool and cure, sink marks may sometimes be remedied by reducing the thickness of the thickest wall sections, which helps to ensure more even and thorough cooling. Inadequate pressure in the mold cavity or higher-than-desirable temperatures at the gate can also contribute to the development of the defects.

On the design side, the risk of sink marks can be minimized by ensuring proper injection molding rib thickness and wall thickness. These actions can also help to increase the overall strength of the part.

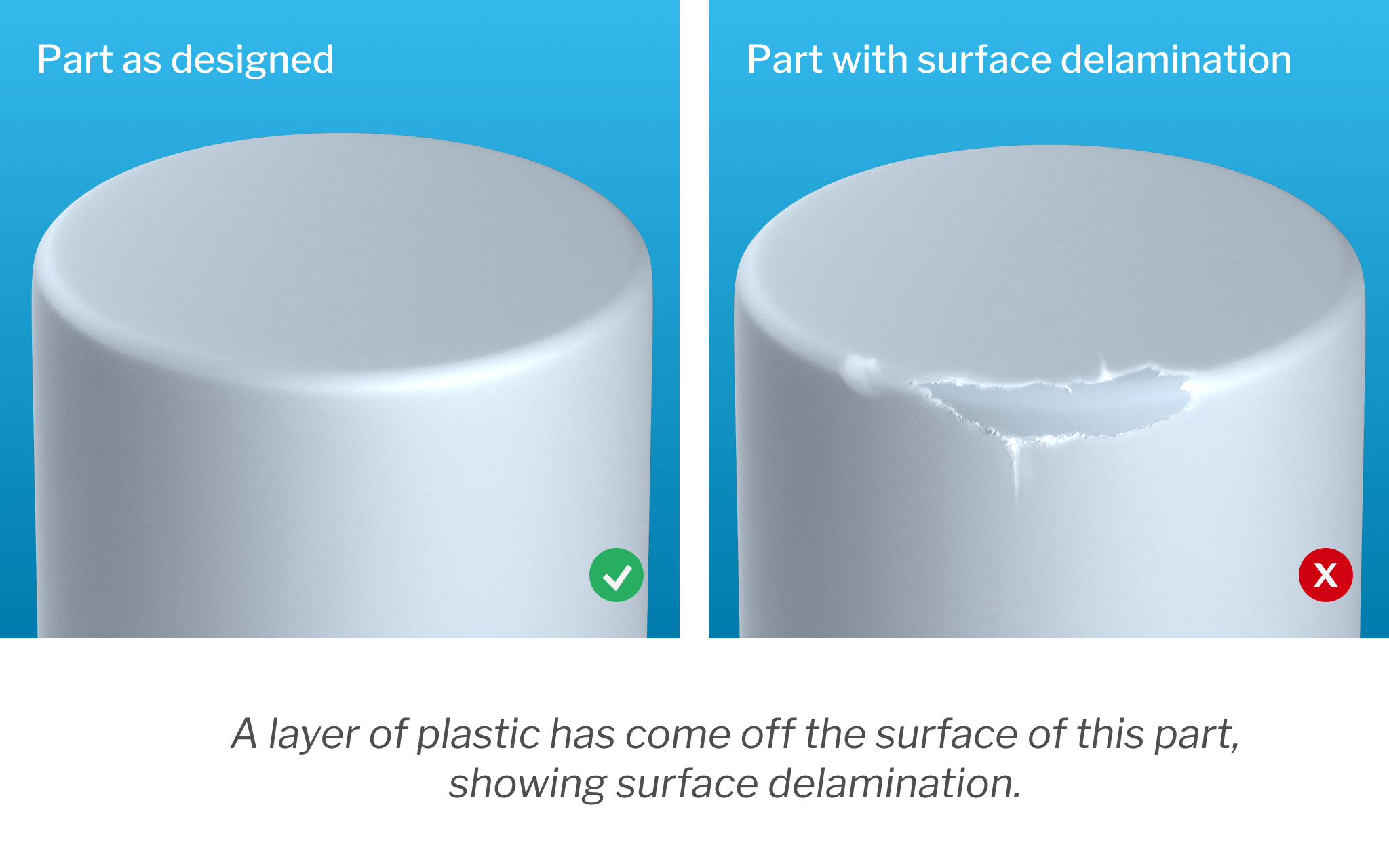

3. Surface Delamination

What is delamination? Delamination is a condition that causes a part’s surface to separate into thin layers. These layers, which appear like coatings that can be peeled off, are caused by the presence of contaminants in the material that do not bond with the plastic, creating localized faults. An over-dependence on mold release agents can also cause delamination.

To encourage delamination repair and prevention, teams should increase mold temperatures and tailor the mold ejection mechanism to be less dependent on mold-release agents, since these agents can increase the risk of delamination. Properly pre-drying the plastic before molding can also help.

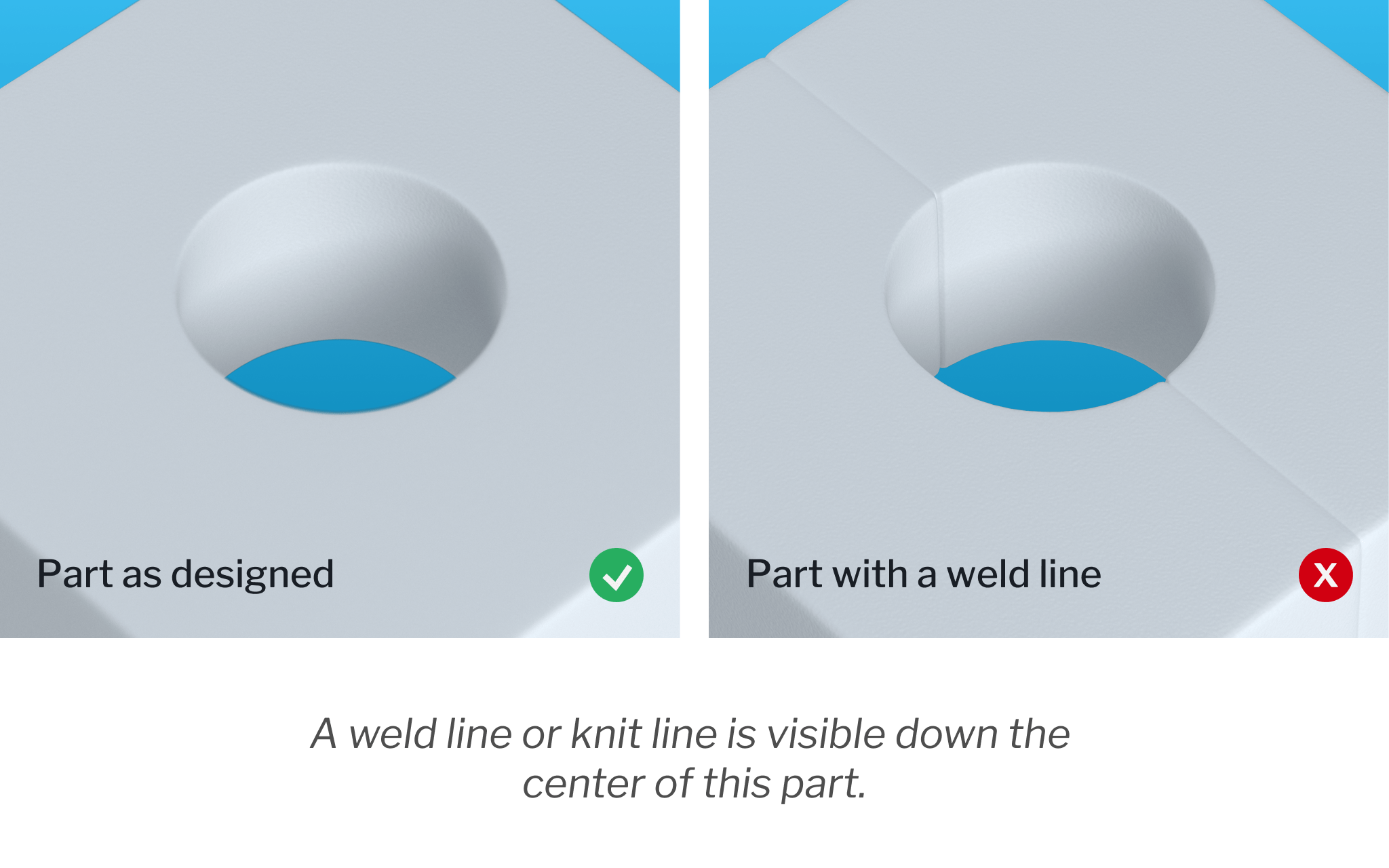

4. Weld Lines

Also called knit lines, these defects mark where two flows of molten resin came together as they moved through the mold geometry. This happens around any part of the geometry that has a hole. As the plastic flows and wraps around each side of a hole, the two flows of plastic meet. If the temperature of the flow isn’t just right, the two flows won’t properly bond together and will instead cause a visible weld line. This reduces the overall strength and durability of the component.

Raising the temperature of the molten resin can help to prevent the solidification process from beginning too soon, as can increasing injection speed and pressure. Resins with lower viscosity and lower melting points are less prone to developing weld lines in injection molding, which can also be eliminated by removing partitions from mold design.

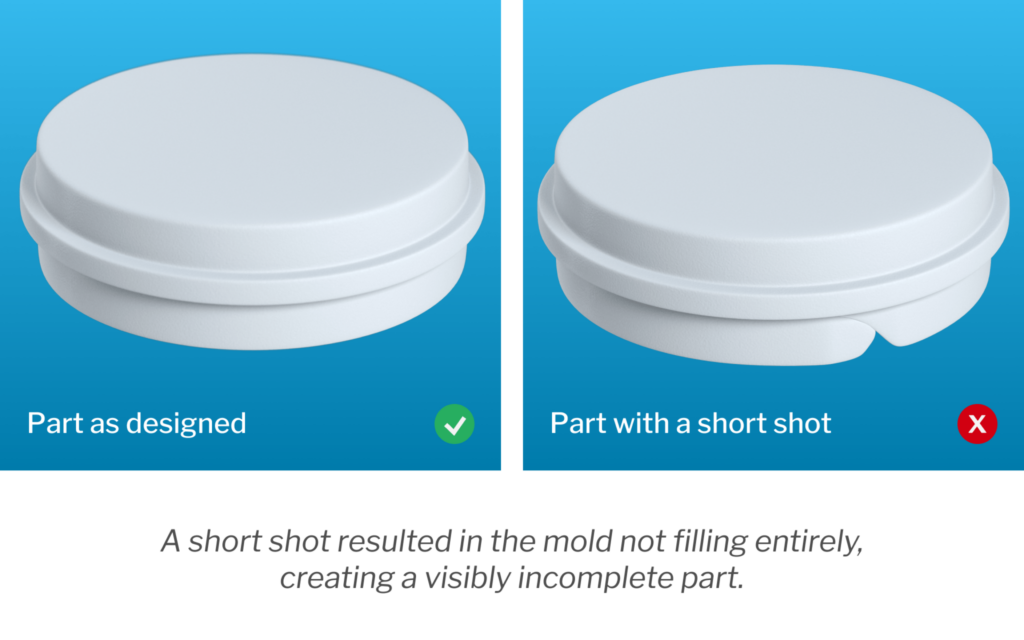

5. Short Shots

“Short shots” refer to instances in which the resin doesn’t entirely fill the mold cavity, resulting in incomplete and unusable parts.

What causes short shots in injection molding? Typically, they are the result of restricted flow within the mold, which can be caused by gates that are too narrow or have become blocked, trapped air pockets, or insufficient injection pressure. Material viscosity and mold temperature are also contributors. Increasing mold temperature and incorporating additional venting into mold design to allow air to properly escape can help prevent the occurrence of short shots.

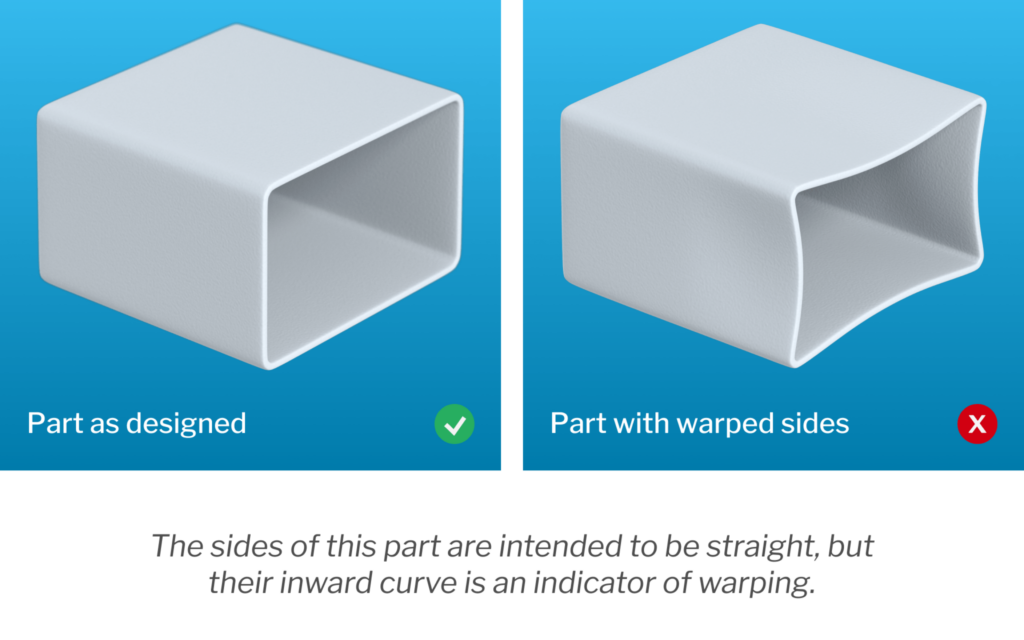

6. Warping

Injection molding warping refers to unintended twists or bends caused by uneven internal shrinkage during the cooling process. Warping defects in injection molding are generally the result of non-uniform or inconsistent mold cooling, which creates stresses within the material.

Preventing warpage defects in injection molding is a matter of guaranteeing that parts are given enough time to cool — and at a sufficiently gradual rate — to prevent internal stresses from forming and damaging the piece. Uniform wall thickness in mold design is crucial for many reasons, critical among them being that it helps ensure that the plastic flows through the mold cavity in a single direction.

It’s worth noting that materials with semi-crystalline structures are more likely to develop warping.

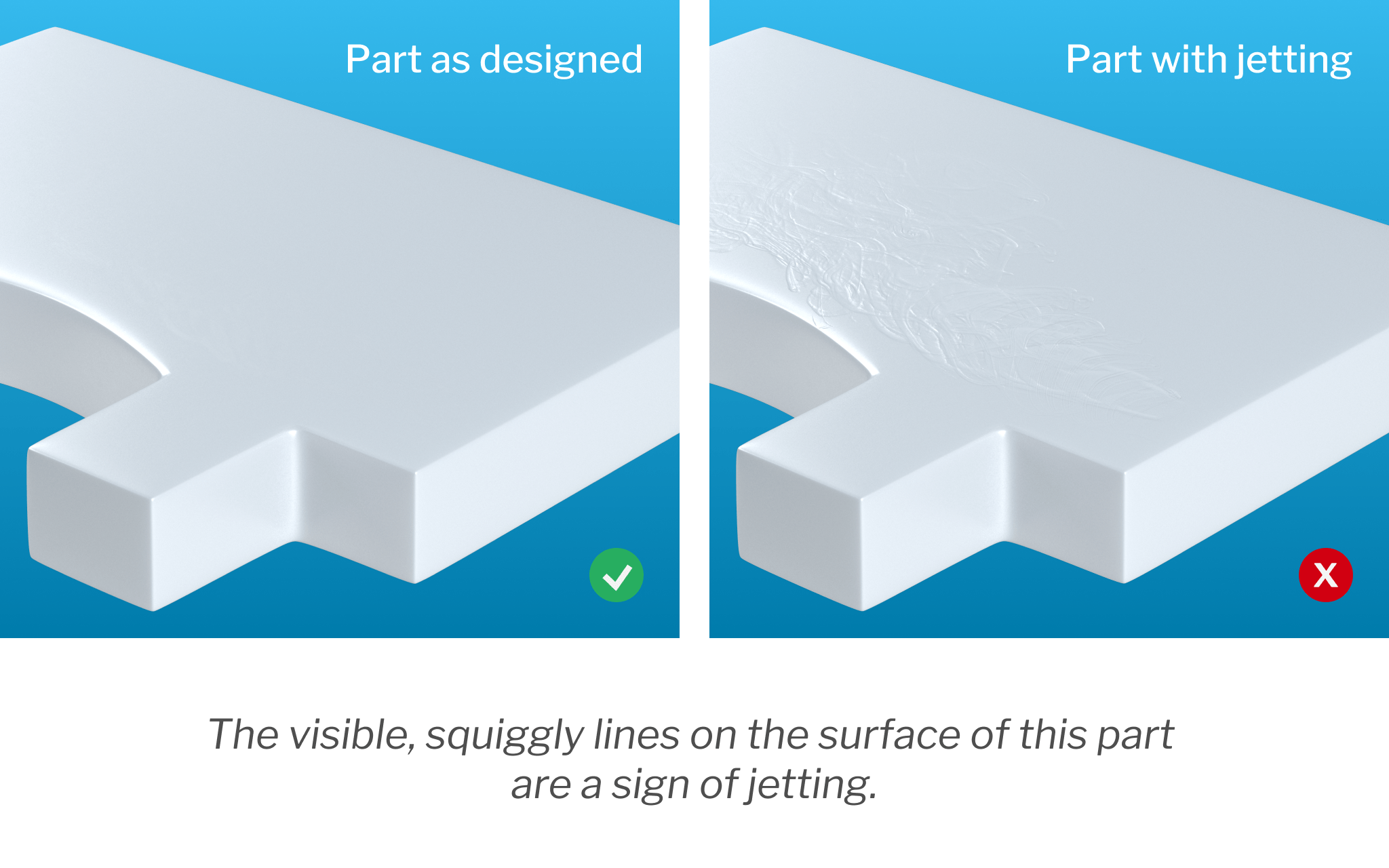

7. Jetting

Jetting defects in injection molding are another potential result of an uneven solidification process. Jetting occurs when an initial jet of resin enters the mold and has enough time to begin setting before the cavity fills. This creates visible, squiggly flow patterns on the piece’s surface and decreases the strength of the part.

Reducing injection pressure is often the best way to ensure more gradual fills, but increasing the mold and resin temperature can also help to prevent any jets from preemptively setting. Placing the injection gate so that the flow of material runs through the shortest axis of the mold is another effective means of minimizing jetting.

Prevent Injection Molding Defects and Causes

Injection molding can be a highly efficient manufacturing method for producing highly repeatable plastic parts, but, as with many processes, producing high quality end-parts requires a high level of attention to detail and a proactive approach to risk management. Everyone involved in the product development process — from the initial design and proof-of-concept stages all the way to fulfillment — needs to do their due diligence to ensure products meet the highest quality standards and avoid these common plastic injection molding issues.

Choosing a manufacturing partner like SyBridge, who is well-versed in common defects in injection molding and their troubleshooting, can mean the difference between high-quality parts — produced on-time and within budget — and those marked with weld lines, jet, flash, sink marks, and other defects. In addition to being an experienced on-demand manufacturing shop, we also provide design consulting and optimization services that ensure we’re able to help every team create functional, elegant, high-performance parts as efficiently as possible. Contact us today to learn more about our injection molding services.