What is Fiber Orientation and Why Does it Matter?

Published on May 4, 2020

Originally published on fastradius.com on May 4, 2020

A composite is a heterogeneous mixture of two or more distinct materials brought together to overcome the individual limitations of each material and make a stronger product overall. The final properties of the composite ultimately depend on the physical and chemical properties of the materials with which it’s made.

However, generally speaking, composites can be mechanically strengthened through the addition of fibers. Strength, elasticity, and manufacturability are all enhanced by fiber reinforcement, but to what degree depends on the position of the fibers themselves, or fiber orientation.

But how does fiber orientation impact the quality and performance of a part in its end-use? Here’s everything you need to know about fiber orientation — plus key considerations for engineers.

What is fiber orientation?

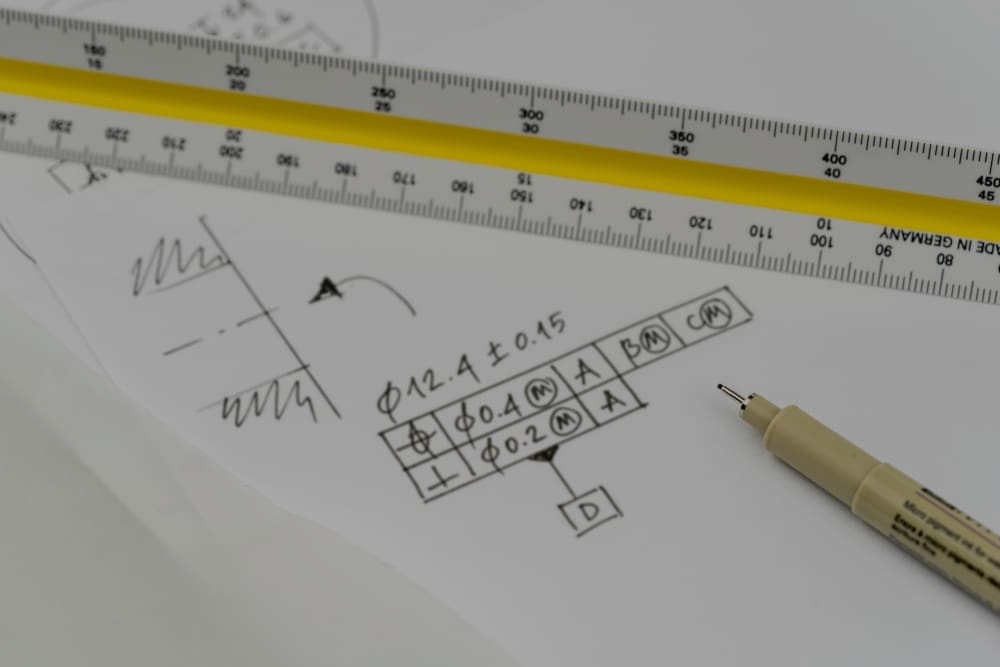

Fiber orientation in injection molding refers to the way individual fibers are arranged to facilitate optimal structural arrangement in a fiber-reinforced polymer composite. As the injected material flows through the mold, the resulting fiber alignment changes the geometry of the mold cavity, which has a direct impact on mechanical properties.

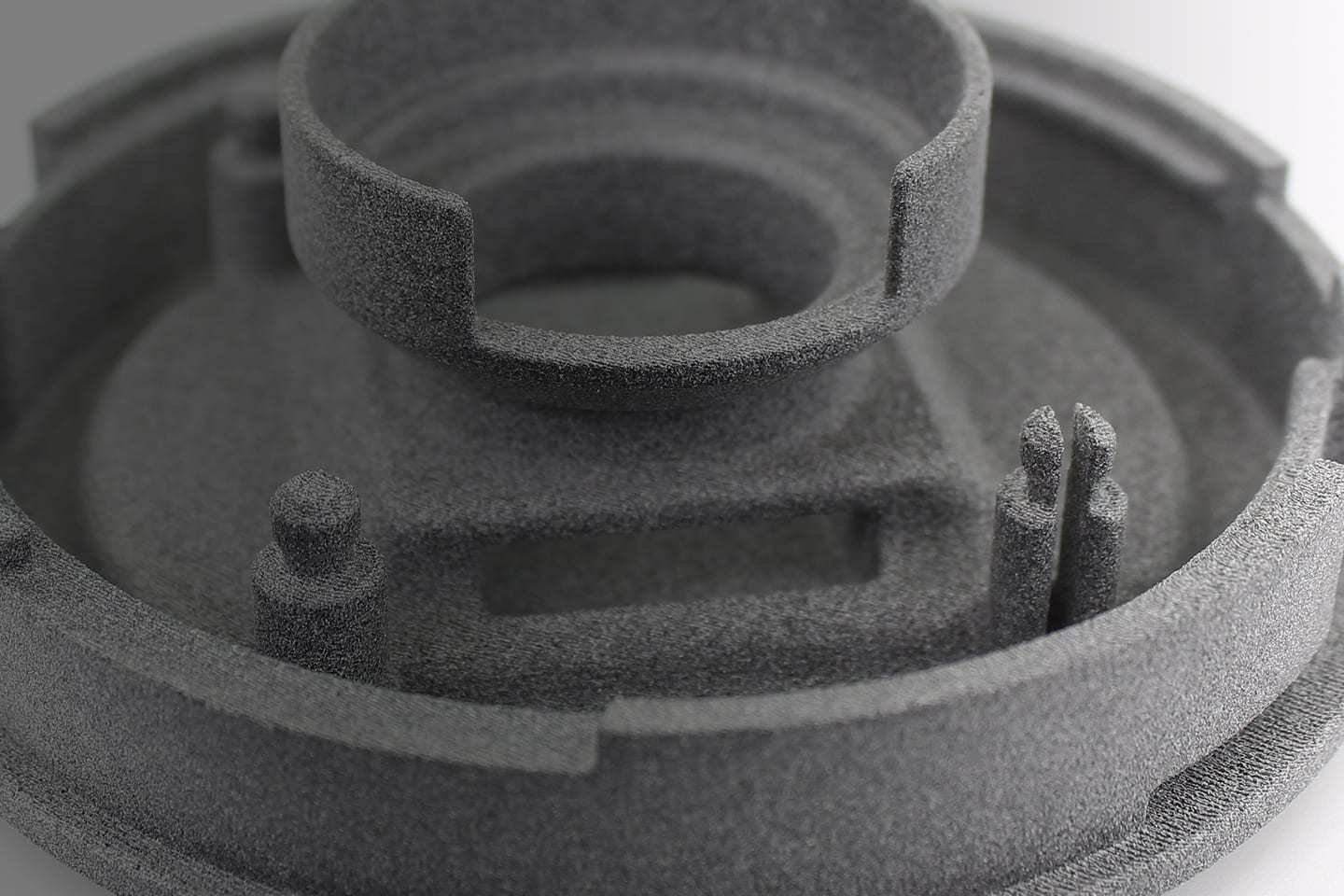

A fiber-reinforced polymer composite (FRP) consists of three parts — the polymer matrix, fiber reinforcements, and the fine interphase region. The polymer matrix, typically a thermoset or thermoplastic, is a binding agent that holds the reinforcing fibers in place during injection molding. It also determines the composite’s degradative properties like chemical resistance or creep. If the matrix is the flesh and the fiber reinforcements are the bone, together they form a strong limb or composite.

FRPs are known for their high mechanical performance, corrosion and wear resistance, durability, and design flexibility. For these reasons, fiber-reinforced polymer composites have wide-ranging applications in aerospace, biomedical, and marine sectors, but they are especially popular in the dental industry.

Engineers can customize fiber-reinforced polymer composites by mixing and matching different matrices and reinforcing fibers to achieve their desired effect. Fiber orientation is the primary way engineers make injection molded materials stronger, and the secret to an FRP’s success.

Glass vs. carbon fibers

A fiber-reinforced polymer composite is only as strong as its composite materials, and that goes for polymer matrices as well as fiber reinforcements. Matrices made out of thermosets like polyesters or epoxies have high dimensional and thermal stability and solvent resistance. Thermoplastics like polyether ether ketone (PEEK), on the other hand, are tougher than thermosets in this case, and any composite made with this polymer matrix would be less brittle.

Fiber reinforcement materials have a tremendous impact on a part’s composite density, mechanical properties, and electrical and thermal conductivities. Generally, the best kinds of fibers for use in injection molding are glass and carbon.

Glass fibers are affordable and have a high tensile yield strength and high chemical/heat resistance. They are also good insulators, perfect for electrical applications. Glass fiber composites also have a much higher tensile modulus than non glass fiber plastics.

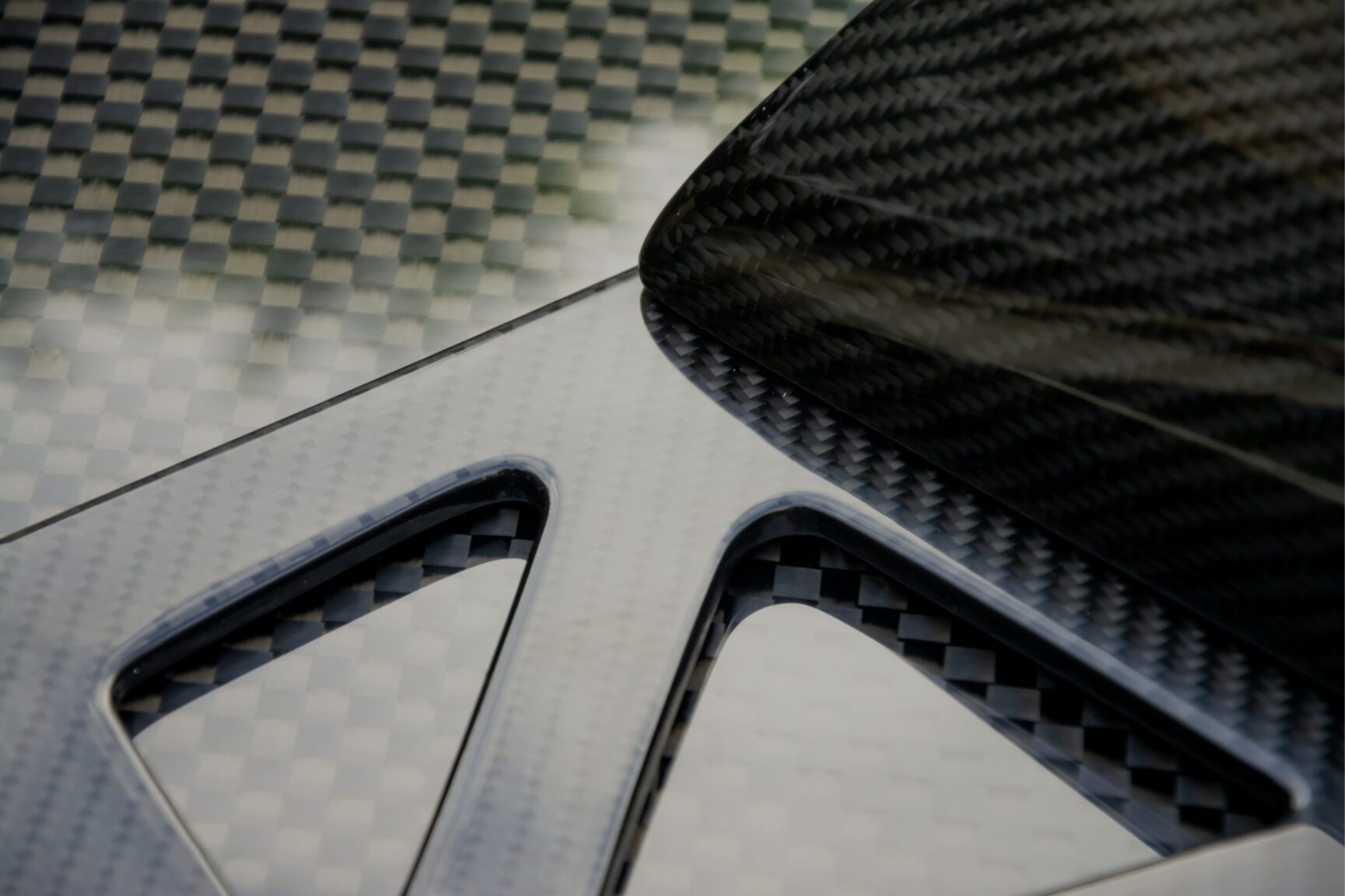

Carbon fibers come in two varieties: polyacrylonitrile-based (PAN) carbon and pitch-derived carbon. Carbon fibers are extremely thermally conductive, with a low coefficient of linear thermal expansion. They also have high tensile strength and modulus, plus high fatigue strength.

Drawbacks to carbon fibers include the fact that they can be relatively cost-inefficient, they have low impact resistance, and they often oxidize in the presence of high heat. Further, the high electrical conductivity of carbon fibers might cause unwanted electrical discharge in unprotected equipment.

Why is fiber orientation in composites important?

Within composite materials, fiber orientation can greatly impact a part’s strength. Four of the most common orientations in fiber-reinforced composites are unidirectional, random, bidirectional, and multi-directional. Regardless of the direction of fibers within the material, fiber orientation can dramatically enhance an injection molded part’s mechanical and chemical properties.

Reinforcing fibers can help evenly distribute a part’s structural load across a network of supportive points instead of placing it all on one or two centralized pressure points. Fiber orientation provides macroscopic stiffness and strength, which plays a vital role in improving a part’s mechanical properties.

What’s more, fiber-reinforced composites benefit from the chemical properties lent to them by their polymer matrices and fiber reinforcements. Glass fibers offer excellent heat resistance while carbon fibers offer superior thermal conductivity. Engineers can imbue their injection molded parts with almost any mechanical or thermal property with the help of fiber-reinforced composites.

Fiber orientation with SyBridge Technologies

Fiber-reinforced composites are as strong as the sum of their parts, which is to say they’re very strong. Composite materials are a good choice for engineers looking to create parts that require high heat resistance, strength, and durability. An experienced manufacturing partner can help you choose the glass or carbon fiber orientation that will make your design as strong as possible.

At SyBridge Technologies, we’ve made it our mission to serve as a one-stop shop for everything manufacturing-related, from design to prototyping to fulfillment. Our team of highly experienced designers and engineers are prepared to provide end-to-end support on any project. Together, we can make new things possible. Contact us today for a quote.