An Overview of Cast Urethane Materials

Published on December 10, 2020

Originally published on fastradius.com on December 10, 2020

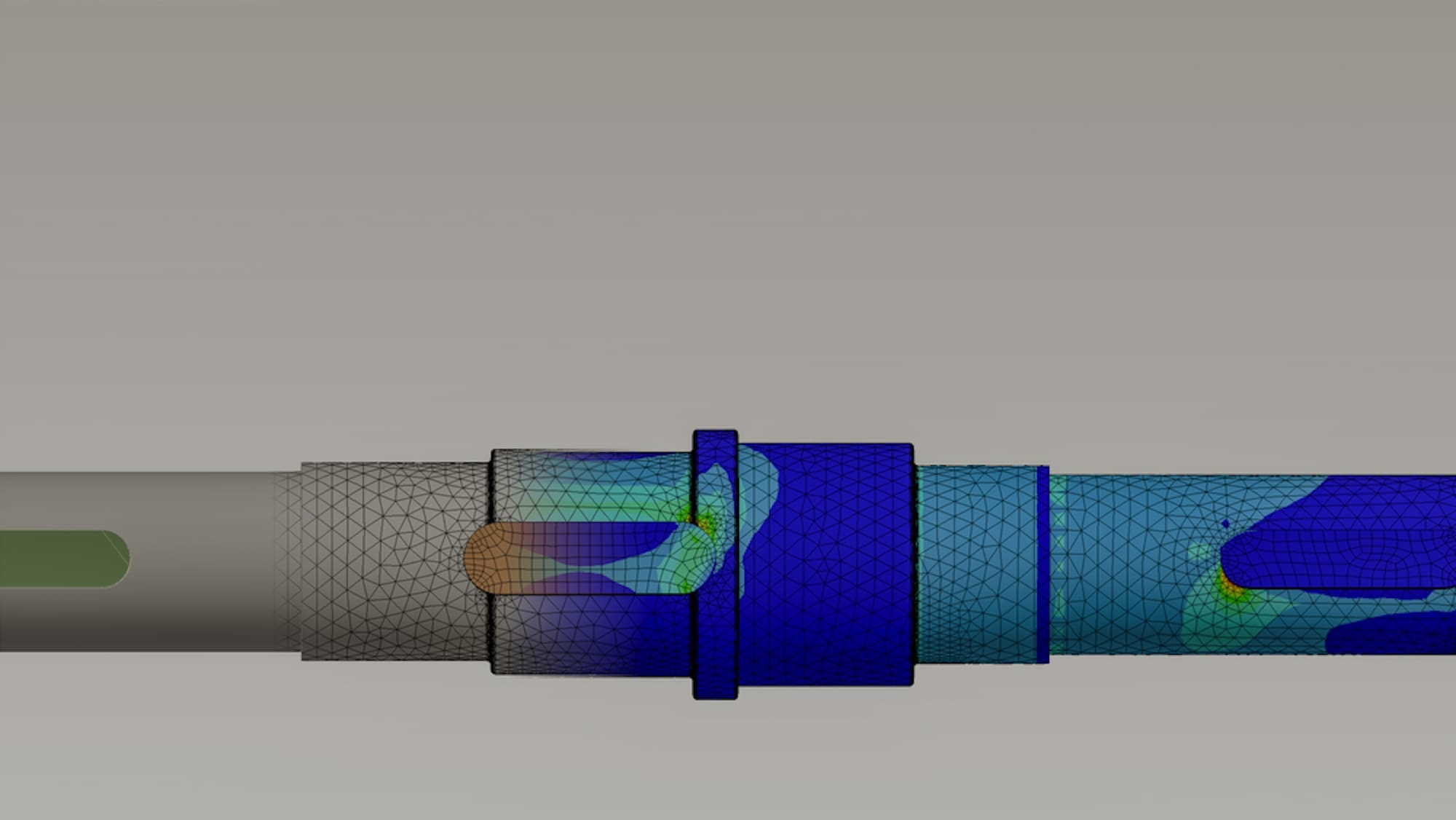

Cast urethane is a manufacturing method that allows designers and engineers to consistently create production-quality plastic parts with a range of material properties. The process begins by placing a master pattern — which is essentially a replica of the desired final part — in a mold box and covering it with liquid silicone. Once the silicone has cured, the block is cut in half to extract the master from the silicone mold. As a final series of steps, the master pattern is replicated by filling the mold with casting resin and curing the part in a heated vacuum chamber.

The process combines the strength of injection-molded parts with high-quality surface finishes and chemical and abrasion resistance. The short lead times and low cost of soft tooling make the process especially useful for prototyping and for low- to medium-volume production that doesn’t warrant the expense or time required for hard tooling.

Cast urethane is compatible with a wide range of materials, and its versatility is a benefit for designers and engineers. However, it’s critical that product teams select an appropriate material based on their specific project requirements — which can include cost, functionality, aesthetics, and other factors — in order to maximize the quality and performance of the final part. Here’s what teams need to know.

Key Considerations for Cast Urethane Material Selection

As with most manufacturing projects, the desired qualities and characteristics of the final part application should inform the material selection process. For example, gaskets, overmolds, and skateboard wheels — while all commonly manufactured via cast urethane — have widely differing performance requirements. In order to provide better sealant and fit, gaskets and overmolds should be made from softer, rubber-like materials, while skateboard wheels need to offer a combination of durability and noise- and shock-absorption.

The urethane resin family is highly versatile and can provide material and performance characteristics comparable to many engineering-grade plastics. Resins can often be augmented with additives, such milled glass fibers and other particulates, to improve the part’s strength, anti-static qualities, flame resistance, or other desirable properties. The material and additive offerings of individual suppliers will vary, but urethane resins are often broadly categorized according to the Shore durometer hardness scale (in which an “A” rating indicates softer, elastomeric materials, and a “D” rating refers to highly rigid materials).

Rigid Polyurethanes

ABS-like polyurethanes are low-cost, general purpose resins that provide comparable — if not better — strength and impact resistance to acrylonitrile butadiene styrene (ABS), a thermoplastic polymer commonly used in vehicle exteriors.

With typical durometers of 80-85 Shore D, these resins make excellent product enclosures and components that will stand up to frequent handling (such as game console controllers). Urethanes are susceptible to UV radiation and will therefore require stabilizers or coatings if used in exterior applications.

Acrylic-like polyurethanes are another common casting material. These resins are stiff and transparent, offering similar properties to polymethylmethacrylate (PMMA), a lightweight acrylic commonly used as a glass substitute. Offering durometers around 87 Shore D, these materials are excellent for creating durable, transparent parts such as light tubing.

Softer rigid resins (such as those that fall between 60 and 75 Shore D on the durometer scale) can also be used to create firm parts with a degree of flexibility, such as car tires or hard hats. These resins have low viscosity and are therefore excellent for filling complex mold designs.

Elastomeric Polyurethanes

Elastomeric polyurethanes offer similar properties to flexible materials like TPE, TPU, and silicone rubber, making them ideal for manufacturing products such as wearable components and bumper pads.

Much like rigid resins, elastomeric polyurethanes come with a number of mechanical advantages. Those with durometers of 50 Shore A and below provide high tensile strength, toughness, and flexibility, while those between 60 and 80 Shore A are well-suited for producing abrasion-resistant parts and fixtures with a degree of flex. Shore A resins can also be used to create urethane casting molds that are more durable than their silicone counterparts.

Hard elastomeric urethane materials include durometers ranging from 90 Shore A to 60 Shore D, and are ideal for demanding industrial applications like forming dies and gears. In some cases, these resins are able to outlast metal patterns.

Getting Started With Cast Urethane

Urethane casting is an efficient and effective process for many manufacturers, as it enables short production timelines, flexible material choice, and inexpensive tooling costs. In addition, polyurethane materials can endow a part with a range of desirable properties — from malleability and heat resistance to high tensile strength and rigidity.

However, a trusted manufacturing partner like SyBridge can ease some of that burden. Our talented team of designers and engineers work closely with every customer, providing expert advice and assistance from ideation through to post-processing and fulfillment. Contact us today to discover how we can optimize the product life cycle for maximum efficiency.