Precision Tooling for Scalable Production

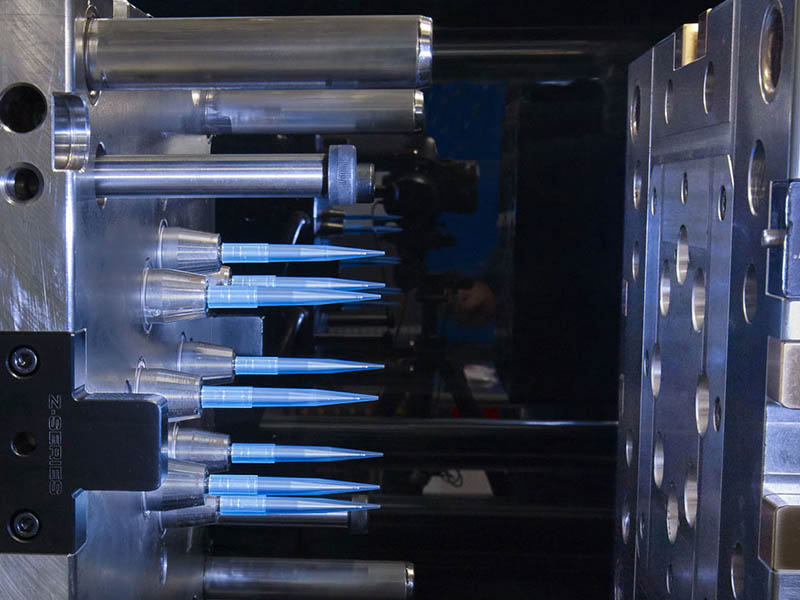

Tooling expertise for optimum total cost of ownership

High-quality tooling for scalable injection molding production volumes

Comprehensive experience in variety of tooling types

Precision tolerances as tight as 0.0002 inches

In-house full-service testing and validation capabilities

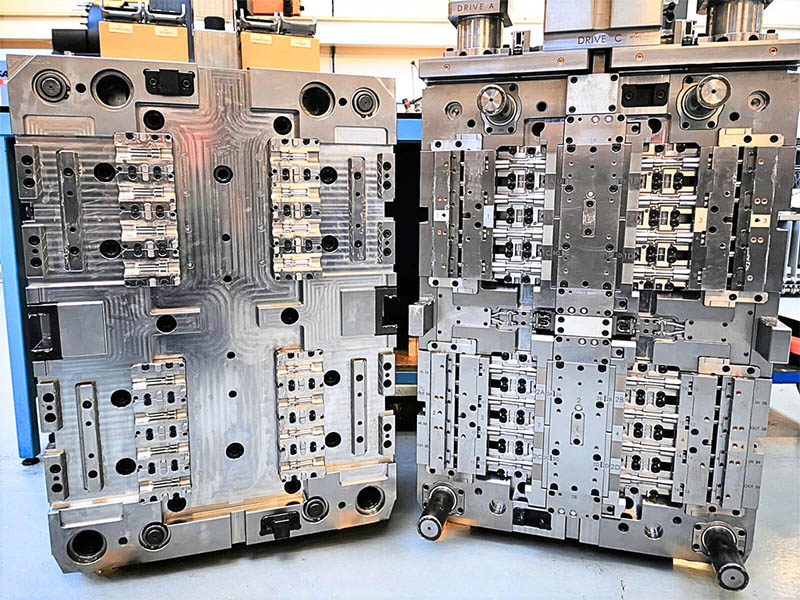

Prototype, Bridge and Production Tooling

With comprehensive capabilities in molding, casting and aluminum tooling, we will take your tooling from concept to production, accounting for your budget and quality requirements at each step.

Mold Types for Tooling Production

Choosing the right mold is a critical step in your tooling development process. SyBridge offers expertise and a myriad of options to find the perfect mold to match your quality, material, speed, volume and budget requirements. Our mold types include:

- Class 101 and Sub-Class 101 Molds

- Plastic Injection Molds

- Silicone Molds

- Thermoset Molds

- Die Cast Molds

- High-Pressure Die Molds

- Compression Molds

- Blow Molds

- Hydroform Molds

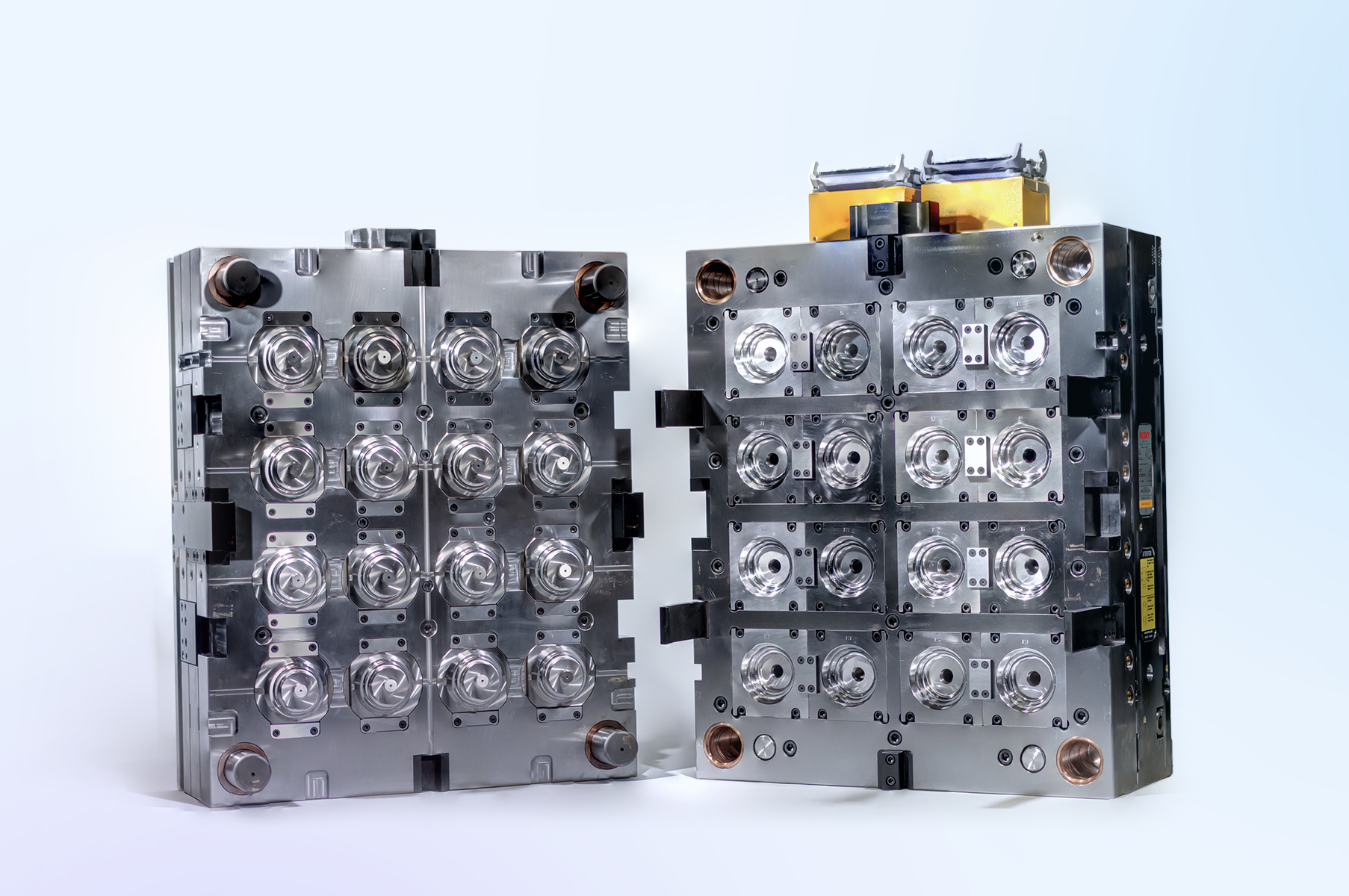

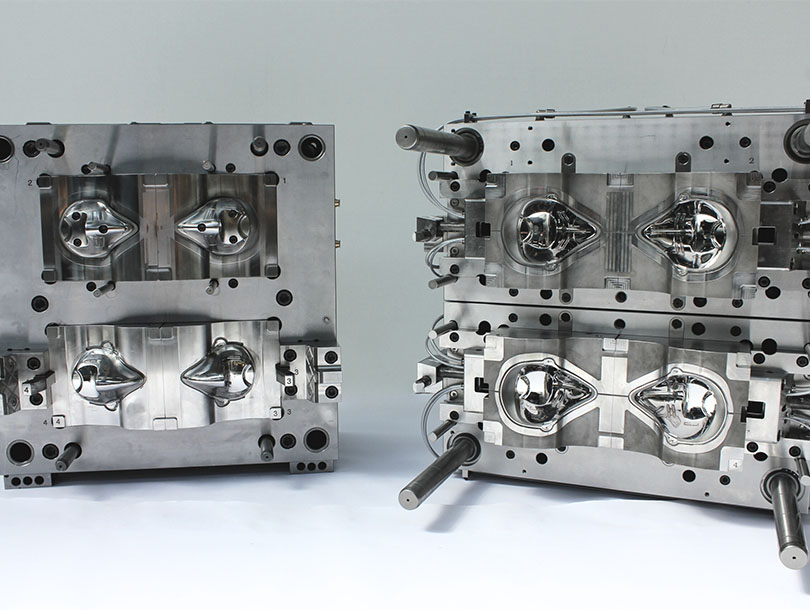

Specialty Tooling Capabilities

For manufacturers that require the highly complex precision tooling, SyBridge has the technology and expertise to offer specialty tooling, including:

- High-Cavitation Molds

- Multi-Shot Molds

- Stack Molds

- Unwinding

- Insert Molds

- Lift & Strip

- In-Mold Closing

- Class 8 Clean Room Molds