Our Injection Mold Tooling Services

Solutions for Every Stage

of Manufacturing

As a trusted partner to OEMs and contract manufacturers, SyBridge provides end-to-end injection mold tooling solutions that support every stage of your program. From prototype to unit tools for early validation to high-cavitation production molds built to withstand millions of cycles, we ensure precision and reliability at every step. Our full lifecycle services help extend tool life, reduce downtime, and protect your investment, keeping your programs running smoothly from concept to long-term production.

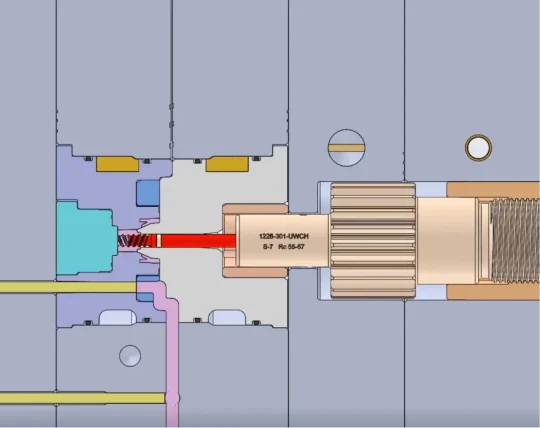

Design & Engineering

Unlock efficiency and innovation with expert tooling design. Our team collaborates with your R&D and manufacturing teams to create production-ready, cost-efficient, and performance-optimized molds. Advanced simulation and DFM/DFX approaches ensure manufacturability, scalability, and long-term reliability before the first steel is cut. The quality of your final product starts here.

Explore Design & Engineering

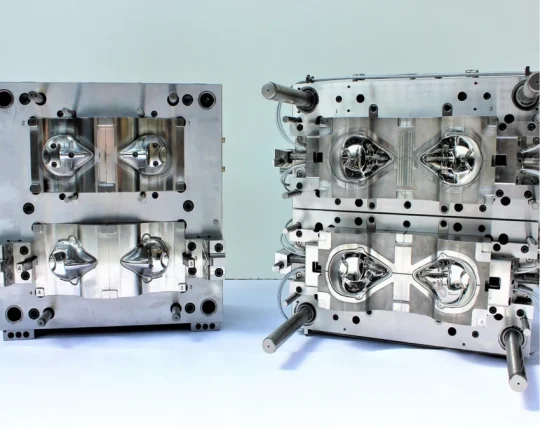

Pre-Production Tooling

Accelerate your speed to market with expert-built prototype and pre-production molds. Validate designs, reduce risk, and iterate quickly using cassette, unit or modular tooling in either steel or aluminum. Our solutions ensure seamless transition from prototype to high-cavitation production tooling.

Explore Pre-Production Tooling

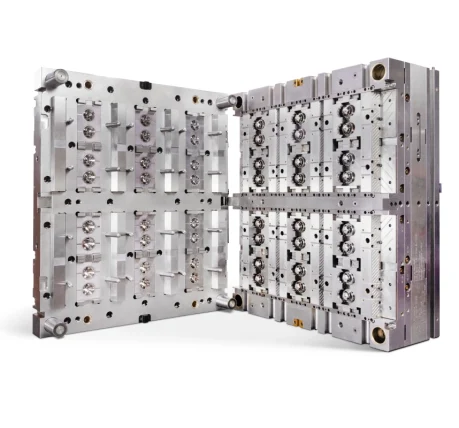

Production Tooling

SyBridge delivers production tooling that drives consistent quality, uptime, and efficiency. Our advanced engineering capabilities and extensive manufacturing network enable the design and build of complex, multi-cavity tools that maintain tight tolerances over millions of cycles–tailored to the needs of the most demanding markets and applications.

Explore Production Tooling

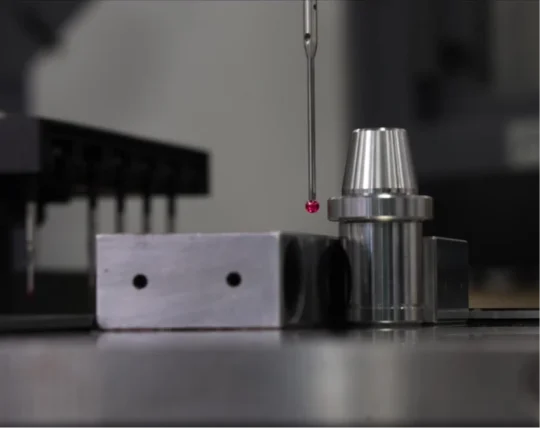

Tool & Part Validation

Ensure every part meets the highest standards and repeatable quality with SyBridge’s turnkey validation services. From complete mold qualification and scientific molding to advanced inspection and documentation, we ensure your molds and parts are repeatable, reliable, and production-ready.

Explore Tool & Part Validation

Repair & Maintenance

A mold is a long-term asset; keep it performing like new with SyBridge’s comprehensive maintenance, repair, and refurbishment services. Our local and global networks offers repairs, rebuilds, and spare components for seamless tool transfers and ongoing production reliability.

Explore Repair & maintenance

FAQs

SyBridge Technologies offers complete injection mold tooling solutions including design and engineering, prototype and pre-production tooling, high-volume production tooling, validation services, and post-production maintenance and repair.

SyBridge Technologies offers complete injection mold tooling solutions including design and engineering, prototype and pre-production tooling, high-volume production tooling, validation services, and post-production maintenance and repair.

SyBridge ensures quality through unified global standards, advanced Design for Manufacturing (DFM) processes, and rigorous tool and part validation. We use high-precision machining, scientific molding principles, and ISO-certified facilities to guarantee tight tolerances and consistent quality to deliver high-performance production molds.

Yes. SyBridge offers comprehensive production support across its global footprint. This includes preventive maintenance, rapid-response precision repairs, mold refurbishment, and tool landing services to maximize uptime and extend the operational life of your production tools.

SyBridge Technologies combines decades of tooling expertise with advanced digital technologies, simulation, and global manufacturing resources to deliver start to finish solutions that ensure speed, quality, and reliability.