Smarter, Greener

Manufacturing

Innovating Responsibly.

Building for Tomorrow.

At SyBridge, sustainability isn’t an afterthought—it’s built into how we design, build, and operate. From advancing sustainable injection molding practices to ensuring responsible sourcing across our global supply chain, we’re committed to creating lasting value for our customers, communities, and the planet.

Sustainable Tool Design

and Production

We integrate sustainable manufacturing practices during tooling design and build to minimize environmental impact and maximize resource efficiency.

Optimized steel utilization

Our design-for-manufacturability (DFM) process selects the smallest

viable stock sizes to minimize material waste.

Runnerless mold designs

Our expertise in runnerless systems reduces plastic waste during molding operations.

Cycle time optimization

Designing for shorter cycles reduces energy use while improving

product quality.

Operational efficiency

Continuous process improvements cut rework and lower energy

consumption during production.

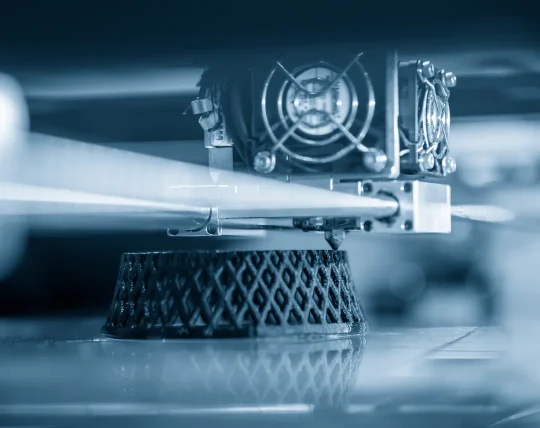

3D Printing: Reducing

and Reusing Materials

Our 3D printing technologies provide sustainable alternatives that minimize material waste and enable more responsible production.

- Less waste from the start: Additive manufacturing uses only the material needed, unlike subtractive methods.

- Resin and powder reclamation: With Carbon® Digital Light Synthesis and HP Multi Jet Fusion™, excess resin and powder is reclaimed and reused.

- Sustainable filaments: FDM printing supports recycled and biobased options, including oyster- and wheat-based Francofil® materials.

Ethically Sourced,

Sustainably Made

Our sustainability standards extend beyond our own operations to our global supply chain. Through our Sustainable Purchases Policy, we require suppliers to:

- Uphold ethical labor practices and human rights.

- Meet strict environmental standards and comply with local and international regulations.

- Act with transparency and integrity throughout the supply chain.

We also expect our suppliers to cascade these values through their own networks, ensuring accountability from raw material to finished product. Non-compliance may result in corrective action or termination.

Strengthening

Our Communities

Sustainability is also about people. We invest in the communities where we live and work by:

- Hosting university and student design events

- Leading manufacturing tours and job fairs

- Partnering with academic institutions to inspire the next generation of engineers and innovators