A Brief History of Plastic Injection Molding

Published on July 13, 2021

Originally published on fastradius.com on July 13, 2021

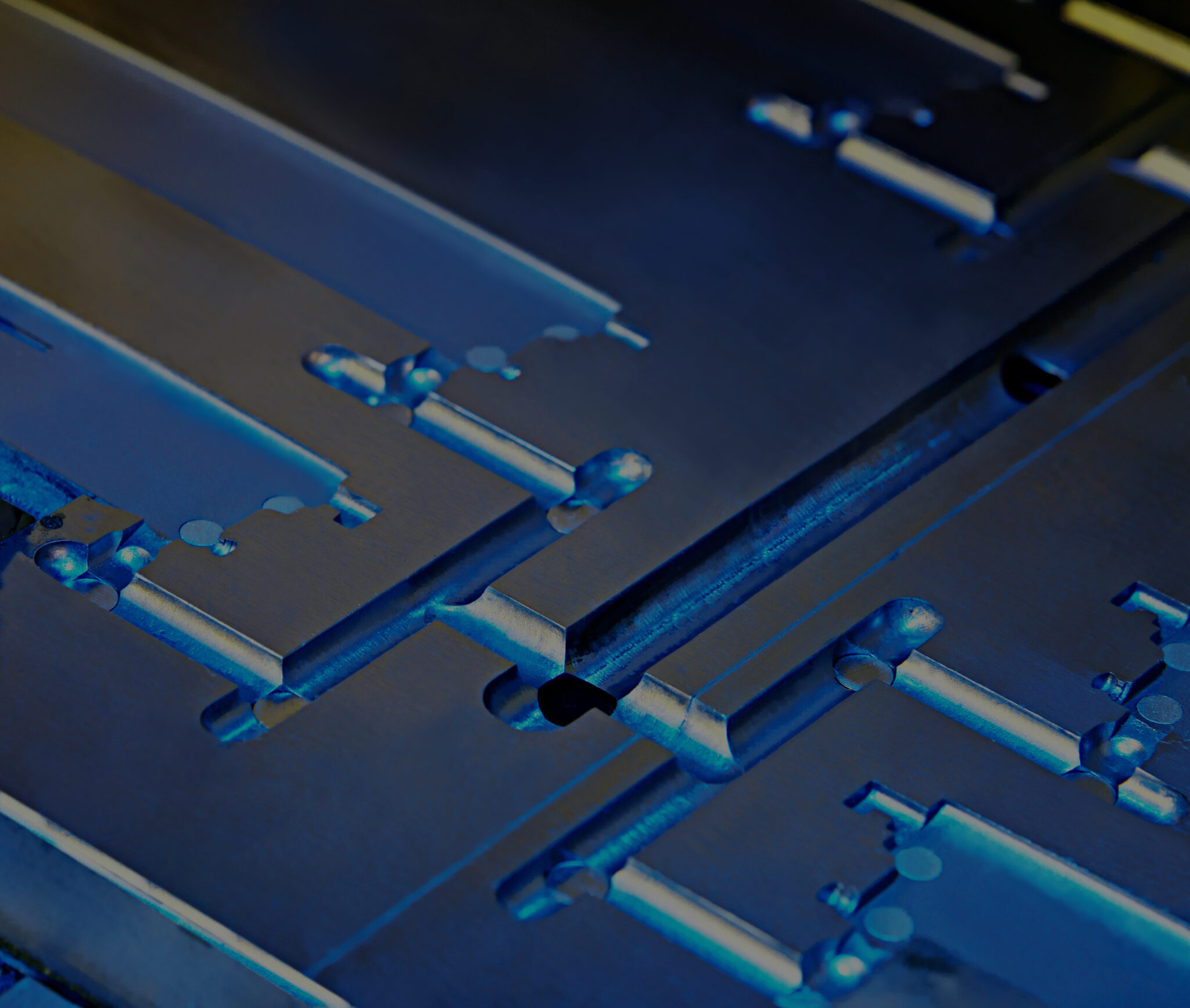

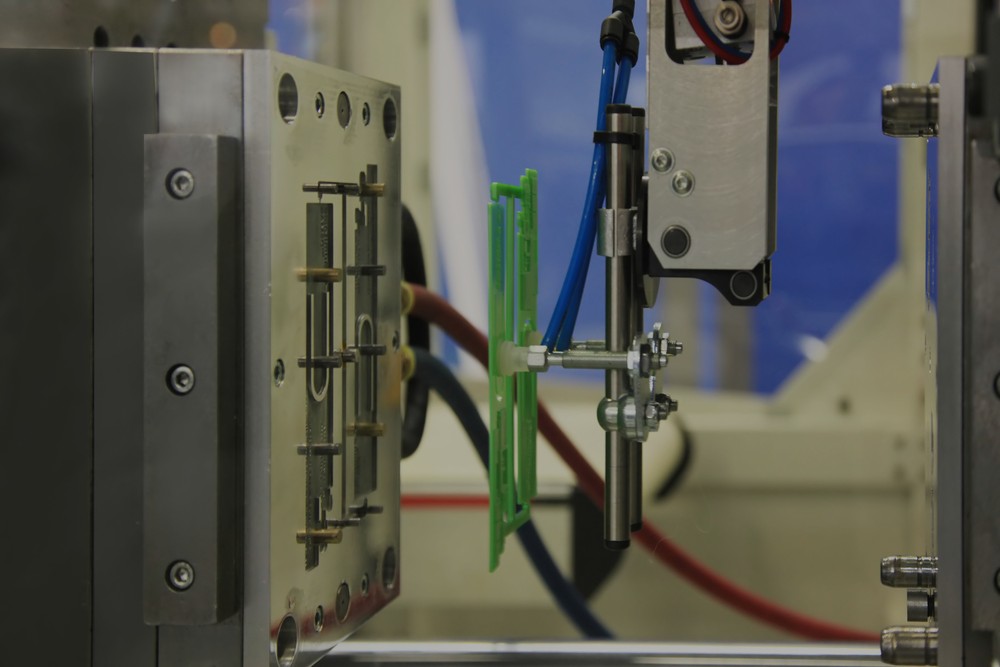

Injection molding is a popular manufacturing process that makes it possible for product teams to quickly create large volumes of identical parts with consistently high quality. The process works by injecting melted plastic through a heated and pressurized nozzle and into a durable, temperature-controlled metal mold. Once the part cools, the mold opens, the part is ejected, the mold closes, and the process repeats.

These molds — typically machined from steel, though aluminum is a common alternative — are time consuming and expensive to make, but the high production volumes dramatically reduce the per-unit cost, allowing both manufacturer and customer to profit. Injection molding is commonly used to create items like plastic water bottles, packaging, mechanical parts, one-piece chairs and tables, and more.

While the process might seem like a relatively recent invention, plastic injection molding has been around for more than a century. In this article, we’ll follow the history of this manufacturing process from its simple beginnings to current day, including the new technologies that are poised to shape the future of injection molding.

The Development and Emergence of Plastic Manufacturing

The history of plastic injection molding begins in 1868 when inventor John W. Hyatt patented the process of creating celluloid, a material originally intended to replace the ivory used in billiard balls. In 1872, Hyatt and his brother Isaiah patented the first injection molding machine, which used a simple plunger mechanism to push celluloid through a heated cylinder and into a mold. The device led to the development of a booming manufacturing industry that produced buttons, combs, collar stays, and other items from celluloid.

Soluble forms of cellulose acetate became available in the early 1900s, offering a much less flammable substitute for previous materials. In the lead-up to World War II, many of the thermoplastics commonly used today — including polystyrene and polyvinyl chloride (PVC) — were developed.

The Impact of World War II on Plastics Manufacturing

Developments in warfare technology, including aircraft, marine battleships, tanks, and other forms of weaponry, consumed vast amounts of raw materials during the course of the Second World War. The post-war industrial boom experienced by many developed Western countries coincided with skyrocketing demand for affordable materials that could be used to mass-produce parts. This was due in large part to how the war disrupted global shipping lanes and required the extraction of huge amounts of natural resources to manufacture tanks, ships, and other war-time products, leading to worldwide shortages of rubber and metal.

Thermoplastics presented affordable options capable of filling many of the market gaps created by these material shortages. Injection molding made it possible for manufacturers to quickly and cost-effectively manufacture parts in large volumes. As markets and supply chains worldwide shifted toward plastic, injection molding emerged as a mainstay and fixture for modern manufacturing companies.

In 1946, James Watson Hendry’s extrusion screw injection machine revolutionized the modern plastic injection molding field. The machine’s rotating screw gave the operator better control over the production process, resulting in significant improvements to the quality of the injection-molded parts. Hendry also pioneered the gas-assisted injection molding process, which made it possible to manufacture long and complex hollow parts.

During the latter half of the twentieth century, plastic materials became more advanced and competitive, offering comparable strength to some metals but at a greatly reduced weight.

Plastic production overtook steel production in terms of market share by the 1970s, and the introduction of lightweight aluminum molds in the 1990s offered a faster, more cost-effective substitute to steel tooling in some instances.

The Future of Plastic Injection Molding

The future is bright for the plastic injection molding industry, with several new technologies showing a great degree of promise.

Internet of Things (IoT) technologies like sensors and automation solutions, for instance, allow for increased connectivity across the entire production system. This provides better visibility into the status of the injection molding process while also better positioning manufacturers to produce higher-quality parts at reduced costs. Automated solutions like robotic unloaders that can stack and unstack parts more efficiently can use programmable setups, sensors, and other IoT features to help shorten production timelines without sacrificing part quality.

Micro-injection molding is another emerging process that applies the mechanisms of injection molding at a microscopic scale. This is especially of interest in medical device manufacturing circles, where the technology could allow product teams to design smaller device assemblies capable of performing potentially life-saving procedures using less-invasive methods and tools.

Eco-friendly injection molding materials are increasingly in demand. While most thermoplastics can be reclaimed and reused simply by melting and re-integrating them, sustainability advocates are pushing for more ambitious goals. Out-of-the-box thinking is leading manufacturers to develop and use materials with less or no thermoplastic content, including next-generation, plant-based materials like corn- and flax-based plastics.

Plastic Injection Molding: Right for Your Part?

Injection molding allows manufacturers to produce parts of consistent quality in massive quantities — a key capability for modern production. Partner with SyBridge for your next job, and we’ll help you get the most out of your production run. Contact us today to get started.