High-Precision

Tooling for Packaging

Excellence

Robust, repeatable solutions

engineered for speed, scale,

and reliability

In consumer packaging, speed, quality, and scale are everything. Whether it’s a complex threaded cap, a thin-wall container, a 5-gallon pail, or a dispensing system, SyBridge helps you launch packaging solutions that perform at scale—faster. Our expertise and end-to-end support mitigate risk, reduce cost, and accelerate time to market while ensuring every part meets consumer expectations.

Delivering Precision Solutions

for Packaging Leaders

SyBridge is more than a toolmaker—we’re a strategic partner in product development and manufacturing. We specialize in complex packaging systems engineered for scaling production in today’s competitive CPG market. Our precision tooling enables packaging solutions that perform under pressure, elevate shelf presence, and protect product integrity.

- Packaging-focused facilities across the US, Canada, Europe, and Asia.

- Cycle time optimization expertise—faster output without sacrificing quality or budget

- Collaborative engineering to balance aesthetics, functionality, and manufacturability

- 50+ years designing complex packaging systems for durability, repeatability, and visual appeal

- Global and local program management with a single point of contact

- Tolerances to 0.0002″ across all steel components

- High-cavitation molds (32, 64, 128-cavity) to maximize throughput and reduce cost per part

- ISO 9001:2015-certified packaging-focus facilities

Solutions for the Most Demanding

Packaging Applications

From industrial pails to personal care packaging, SyBridge delivers tooling that meets high-volume demands while supporting brand identity and consumer experience.

Caps, Closures & Dispensing Systems

Closures are more than function—they can be the gateway to your brand, often the first touchpoint for consumers and a defining element of product experience. SyBridge’s highly complex and and tight-tolerance tooling ensures your caps, closures, and dispensing systems deliver consistent sealing and dispensing, reinforcing your brand’s quality from the first interaction for a memorable brand impact.

- Closures: threaded, flip-top, snap-top, disc-top

- Dispensing systems: actuators, pumps, pour spouts, trigger sprays, aerosols

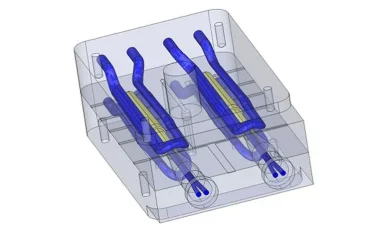

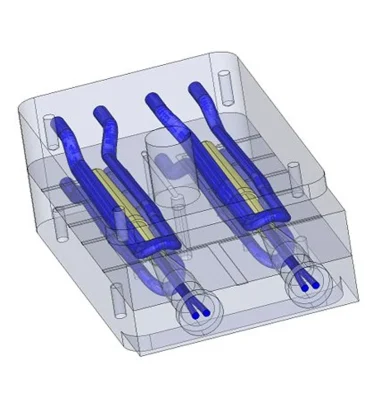

Thin-Wall Packaging

High-speed tooling for thin-wall food and product packaging requires precise engineering to prevent warp, ensure fill balance, and maintain fast cycle times. SyBridge excels at robust tooling with advanced design, conformal cooling, and robust tooling construction to produce lightweight, sustainable containers that reduce material costs and transportation weight. Common end-use products include:

- Food storage containers

- Food packaging (trays, tubs, clamshells)

- Sustainable packaging solutions

Pails & Buckets

As one of North America’s largest pail and bucket tooling manufacturer—and consistently ranked #1 for fastest cycle times—SyBridge sets the standard for high-performance production. Our advanced molds help you achieve ultra-tight tolerances for an exception seal integrity to prevent leaks and safeguard product quality. Designed for industrial and food applications, our engineered solutions ensure your products remain protected from production to shelf, with reliable performance at every cycle.

- Small to large sizes

- Round and square configurations

- Snap-on or threaded lids

- Robust designs for stackability

Beauty & Personal Care Packaging

Our tooling combines aesthetic excellence with precise functionality for personal care, cosmetics, and homecare products. We deliver solutions that ensure consistent quality and flawless performance. We’re experts in applications including:

- Cosmetic containers and compacts

- Dispensing containers and lids

- Deodorant and lip balm sticks

- Tampon applicators

- Contact lens and homecare containers

FAQs

We design and build precision tooling for a wide range of packaging applications, including pails and buckets, thin-wall food packaging, beauty and personal care containers, caps, closures, and dispensing systems.

Our engineering teams optimize cycle times through advanced cooling designs, high-cavitation molds, molds, precision machining, and over 50 years of experience.. Techniques such as conformal cooling can shorten cycle times by 20–40% while maintaining dimensional accuracy and repeatability.

Yes. We have deep expertise in high-cavitation molds (32, 64, 128 cavities) that maximize throughput, reduce cost per part, and ensure consistent performance across millions of cycles.

We deliver tolerances to 0.0002″ across all steel components, allowing us to meet the most demanding requirements for complex packaging systems.