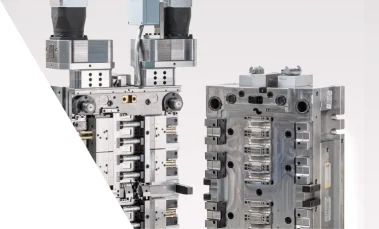

Advanced Tooling

Solutions for Critical

Medical Applications

Powering the next generation

of drug delivery, diagnostics,

and surgical devices

From high-volume drug delivery systems to intricate diagnostic devices, SyBridge delivers best-in-class injection mold tooling that meets the uncompromising standards of medical and pharmaceutical manufacturing. In healthcare, precision isn’t optional—it’s essential. Tooling is the foundation of scalable, compliant, and repeatable production, and our expertise ensures your products perform flawlessly every time.

Your Foundation for

Manufacturing Success

At SyBridge, we help you minimize risk and maximize results by delivering the precision tooling your products demand. From design through production, we craft every tool with meticulous attention to detail, ensuring tight tolerances, high repeatability, and consistent quality for critical healthcare applications.

- State-of-the-art medical focused manufacturing facilities across North America and Europe

- Collaborative engineering to align design intent and manufacturability

- Tolerances to 0.0002” across all steel components

- ISO 13485:2016 and ISO 9001:2015-certified sites

- Class 8 cleanrooms

- Robust tool and part validation (FAI, CMM, OGP, SmartScope, in-house IQ/OQ/PQ)

- Specialty tooling solutions (rapid & prototype tooling, pilot, unit & pre-production, high cavitation etc.)

Solutions Engineered for

Healthcare’s Most Vital Applications

We specialize in precision tooling for a wide range of healthcare submarkets and applications.

Drug Delivery Systems

Precision tooling is critical for ensuring reliability, dosing accuracy, and patient safety in drug delivery devices. SyBridge provides specialized tooling for a wide range of life-critical devices, supporting manufacturers in producing high-quality, consistent components that perform exactly as intended. We are experts in:

- Complex auto injectors and pen injectors

- Inhalers

- Syringes

- Infusion pump and sets

- IV catheters and cannuals

- Opthalmic and ocular delivery products

- Wearable drug delivery devices

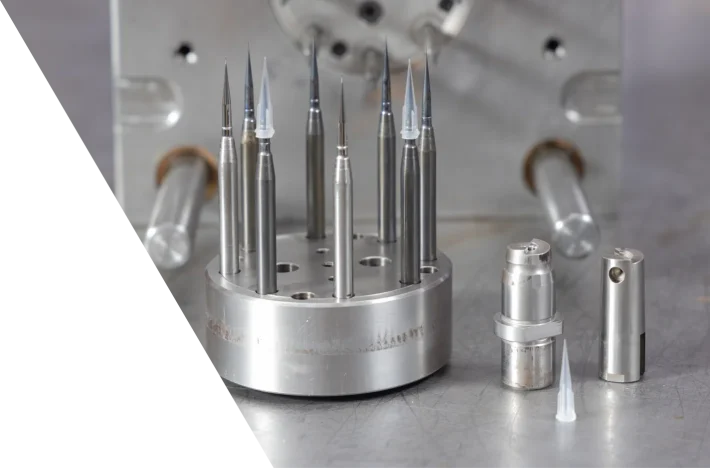

Diagnostics

Accurate and repeatable results start with high-precision components. SyBridge enables diagnostic manufacturers to produce consistent, reliable parts for laboratory and point-of-care testing, helping ensure performance, compliance, and ease of use across a variety of applications such as:

- Pipettes and

pipette tips - Cuvettes

- Microfluidic cartridges

and chips - Assay trays

- Multiwell plates

- Sample collection devices

Medical Consumables & Disposables

Our tooling is designed for high-volume, efficient, and repeatable production while meeting strict medical quality standards. SyBridge supports manufacturers in producing critical single-use items and consumables that must perform reliably in clinical, hospital, and laboratory environments including:

- Vial adapters and IV components

- Infusion sets, valves and clamps

- Dosing cups, scoops, and oral syringes

- PPE and other single-use items

Medical Devices

& Surgical Equipment

SyBridge tooling supports the manufacture of complex, high-precision components essential to the safety, reliability, and performance of medical and surgical devices. Our solutions help OEMs and contract manufacturers produce parts that meet the most demanding regulatory and functional requirements in both clinical and surgical applications such as:

- Laparoscopic devices

- Instrument handles, hubs, and strain reliefs

- Cardiovascular devices (catheters, closure systems)

- Orthopedic device components

- Multi-lumen joiners and other specialty parts

- Endoscope components

Veterinary

Our tooling enables precise, durable production of components for the veterinary market, supporting animal health and care. From medical devices and implants to diagnostics and consumables, SyBridge helps manufacturers produce parts that meet rigorous standards for clinics, hospitals, and research facilities, including:

- Medical device components

- Sample collection and diagnostic tools

- Veterinary-specific syringes, injectors, and dosing systems

- Consumables and single-use items for clinics and labs

FAQs

Yes. Our ISO 13485:2016 and ISO 9001:2015-certified facilities provide full validation support, including FAI, CMM, OGP, SmartScope, and in-house IQ/OQ/PQ processes, ensuring compliance from design through production. For more info, visit our Tool & Part Validation page

We build tooling for a wide range of submarkets, including drug delivery, diagnostics, surgical devices, consumables, and veterinary applications—always engineered for reliability, repeatability, and performance.

Yes. We offer rapid, prototype, pilot, and pre-production tooling solutions to help you accelerate development, validate designs, and scale seamlessly into full production. Learn more about our pre-production tooling offerings.