Your High-Volume

Additive Manufacturing

Partner

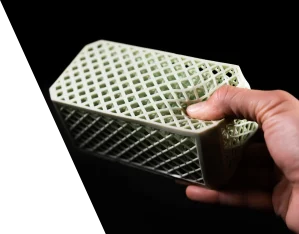

Unlock advanced geometries

and scale with speed, precision,

and consistency.

We are North America’s fastest-growing 3D printing production manufacturer, trusted by leading companies to deliver high-quality, end-use parts at scale. Backed by deep additive manufacturing expertise and significant investment in Carbon® Digital Light Synthesis, SyBridge provides the speed, precision, and consistency you need. Beyond production, we also offer rapid 3D prototyping to support every stage of your product lifecycle.

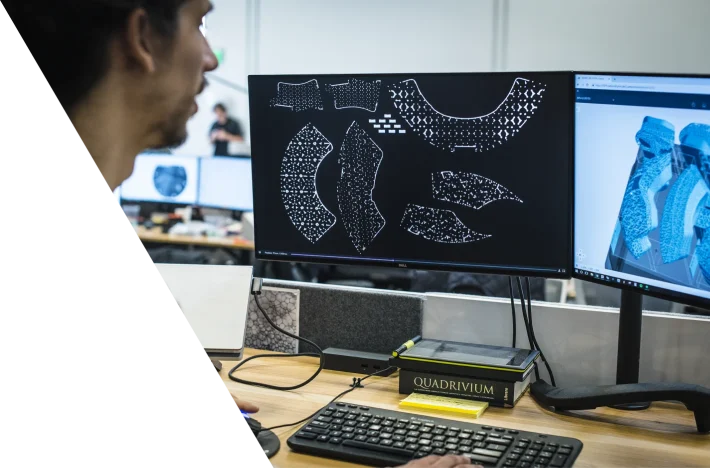

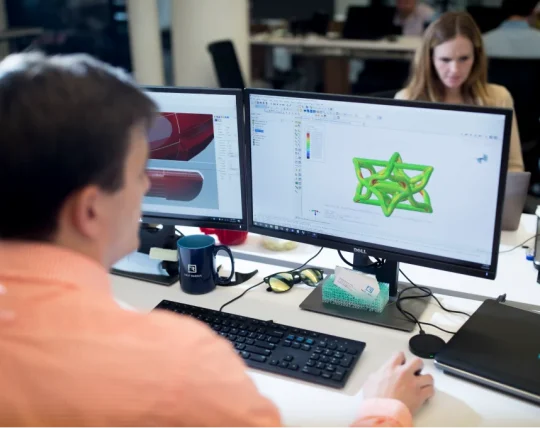

Full Range of Additive Manufacturing Services

Why Choose SyBridge for 3D Printing?

- Industry-leading scale: We have one of the fastest-growing additive facilities, including the #1 production capacity for high-volume DLS elastomer parts in North America

- Technology breadth: 3 leading 3D technologies covering a wide range of applications and geometries

- Wide material selection: 60+ plastic and elastomeric materials meeting demanding mechanical, thermal, and aesthetic requirements

- Engineering partnership: Expert support to recommend the right technologies, optimize designs, and scale efficiently to production

Carbon® Digital Light Synthesis (DLS)

DLS uses digital light projection, oxygen-permeable optics, and programmable resins to rapidly produce isotropic, functional parts with excellent mechanical properties.

Ideal for: High-fidelity end-use parts with complex geometries, smooth surface finishes, and injection-molding-like strength.

Available Materials:

Rigid: EPX 82, EPX 86 FR (flame retardant), EPX 150, FPU 50, IND 147, IND 405, MPU 100 (biocompatible), RPU 70, RPU 130, UMA 90

Non-Rigid: EPU 40, EPU 41, EPU 45, EPU 46, HDT 230, SIL 30

HP Multi Jet Fusion™ (MJF)

MJF builds parts by jetting agents onto a powder bed and fusing them with infrared energy. It produces durable, watertight parts with fine feature resolution and excellent detail, and can support full-color printing.

Ideal for: Functional prototypes, complex assemblies, and color applications like housings, enclosures, and consumer products.

Available Materials:

Standard: Nylon PA-11, Nylon PA-12, PA-12 GF, PP, and TPU

Color: CB Nylon PA 12

Stratasys Fused Deposition

Modeling™ (FDM)

FDM extrudes thermoplastic filament layer by layer to build parts. Known for its material strength, low cost, and scalability, FDM is suitable for both prototyping and functional end-use parts.

Ideal for: Large, strong, and cost-effective parts, especially in production-grade thermoplastics.

Available Materials:

ABS-ESD7, ABS-M30, ABS-M30i, Antero 800NA (PEKK), Antero840CN03 (PEKK), ASA, Nylon PA-6, Nylon PA-12, Nylon PA-12 CF (Carbon-Filled), PC-10, PC-ABS, PC-ISO, PPSF, ST-130, Ultem 1010, Ultem 9085, Ultem 9085 CG

FAQs

Yes. Our team offers DfAM (Design for Additive Manufacturing) expertise to help optimize part geometry, reduce cost, and ensure the best performance in production.

Production lead times vary case by case depending on material, technology, and order size. For small orders (e.g., prototyping), parts ship within 5 days of receiving your order.

We typically work with STL, STEP, and IGES files, but our engineering team can accommodate most common CAD formats.

Absolutely. We provide material certification, production validation, and quality documentation to meet demanding industry requirements.