Originally published on fastradius.com on by August 11, 2021

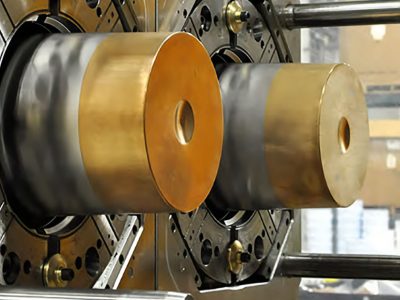

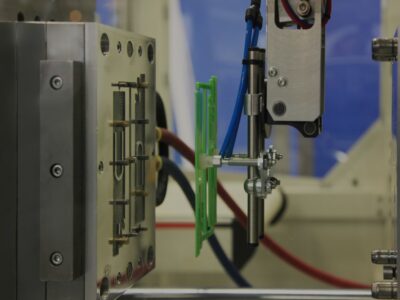

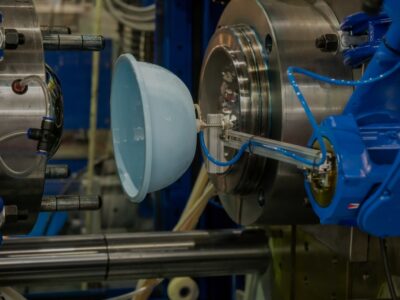

Injection molding is a versatile manufacturing process that generally involves injecting molten plastic resin into durable metal molds, which enables the production of high volumes of identical parts. While injection molding can be incredibly cost effective at scale, plastic parts usually go through design reviews, 3D printing, simulations, and testing before injection molding a final product. Here are a few tips to keep in mind as you’re designing plastic injection molded parts that will help improve the strength of the final product.

Material selection: Foundational to creating strong parts

First, a quick note about material selection. It may seem obvious to say, but the particular materials your components are made of will have a significant impact on the durability, strength, and toughness of the final part or assembly. One simple way to improve the strength of your parts and assemblies? Use stronger thermoplastics. Here are a few common injection molding materials to consider if you’re specifically looking to improve the strength of your injection molded parts.

ABS

Acrylonitrile butadiene styrene (ABS) is an impact-resistant engineering thermoplastic that has both domestic and industrial uses — everything from remote controls and electronics housings to compressors and manufacturing nebulizers can be made from this affordable resin. However, ABS is susceptible to weathering and stress cracking when introduced to certain chemicals.

Polycarbonate

Also known as PC, this plastic offers incredible impact resistance (even more than ABS) and can be made transparent, making it a common alternative to glass. Consumer goods like protective goggles, face shields, interior and exterior signage, and windows are manufactured from this resin, which is also occasionally used to protect building exteriors. While resistant to impacts, PC is prone to scratching and expensive to work with.

Nylon

Nylons are a versatile family of plastics that are well-suited for applications that require a low friction coefficient paired with good wear-and-tear, chemical, and thermal resistance. While unfilled nylon tends to have a degree of flexibility and stiffness, stabilizers and additives can be incorporated into the material to optimize specific properties of the part. Glass fibers, for instance, improve the compressive strength, stiffness, and heat deflection temperature of the material while also making it brittle. Nylon is prone to absorbing moisture from its surroundings and is easily damaged by UV light without the use of stabilizers.

Acetal

Acetal is valued for its stiffness, low friction coefficient, and resistance to abrasion, water, and chemicals. Acetal is commonly used to produce electronics, zippers and gears, automotive components, parts for the food industry, and many other applications. Acetal is not compatible with additive manufacturing technologies and therefore tends to be used less for prototyping than nylon. It is also not well suited for cosmetic parts or those that require paint or printing.

Design tips for building stronger parts

Avoid thick sections

Cooling time, typically the longest stage of the injection molding process, is determined by the thickest sections of the part. Longer cooling time means longer cycle time, which in turn increases the cost of production. Thicker cross-sections also increase the risk that different sections of the part will cool at different rates, which can lead to defects like warping and sinks.

Injection molding as a process is generally stable and consistent when used to produce parts with wall thicknesses ranging from 0.040” (1.016mm) – 0.140” (3.556mm), but the ideal nominal wall thickness will vary by material. Parts with wall thickness greater than 0.120” (3mm) are generally moldable but often require additional attention to ensure that the mold cavity fills during each cycle. Around 0.150” (3.8mm), cross-sections become prone to developing sinks, making additional processes or support necessary in order to maintain part viability.

Reinforce walls or bosses with ribs

Walls and bosses are two features that often exceed the maximum wall thickness guidelines above, in part because they must be sufficiently strong in order to function properly. Ribs add strength to key areas that require greater-than-nominal wall thickness, embossed features, and tall walls — all without impacting cycle time. In some cases, incorporating more ribbing into the part design can reduce material usage.

To minimize the risk of sinks or voids as the part cools, the wall thickness of a boss should be 40-60% of the component’s nominal wall thickness. Bosses should be fixed in place with ribs or fillets to minimize warping. Bosses can introduce additional stress points, but they can actually reinforce stress points in a part’s design if they are properly incorporated.

Use fillets and radii to strengthen corners

Sharp corners are no one’s friend in manufacturing, especially for injection molded parts. The solution for getting around corners? Fillet radii and round radii. The two are similar — fillet radii being the rounding of an internal corner and round radii the rounding of a part’s external corners.

Rounding inside corners provides a number of benefits, including improving the part’s load-bearing strength while helping to mitigate stress concentration. This also ensures a more uniform cavity fill during production, which helps prevent corner material from expanding and cracking part quality. Fillet radii can be added between bosses and ribs, connecting them to nearby walls for additional strength. Rounding an outside corner further helps to increase load-bearing strength, reduces the likelihood of fractures, and removes difficult-to-fill corners from the part design, making it easier to guarantee more consistent mold fills.

Improve the strength of your injection molded parts with a skilled expert

Durability and toughness aren’t the only material properties that product teams are after — finding the right balance between strength, function, affordability, and other desired material characteristics is vital. Otherwise, you run the risk of ending up with a part that’s too flexible or too brittle.

Working with an experienced manufacturing partner like SyBridge means you get to rest easy. Our team works hard to help each of our customers optimize their designs and provide the insight needed to ensure that every part we produce with you exceeds expectations when it comes to part strength, production schedule, and cost. Ready to get started? Contact us today to hear more about our injection molding services.