Global Capabilities Backed by State of the Art Technologies

Integrating innovations in value-added manufacturing and digital design

Solutions for every step of the manufacturing process

From end-to-end, our industry-leading capabilities give you the highest quality results with maximum efficiency.

Technology-enabled solutions for high-precision products

Expertise in AI and computational geometry

Large qualified network for scalable capacity

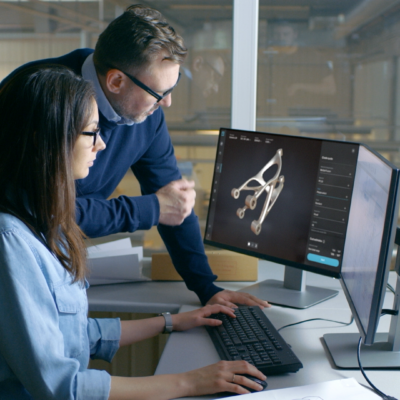

Design & Engineering

Design is the first and most critical step in the manufacturing process. Team up with SyBridge’s expert engineers to access all the resources you need to optimize your design for form, fit and function.

Our design capabilities include:

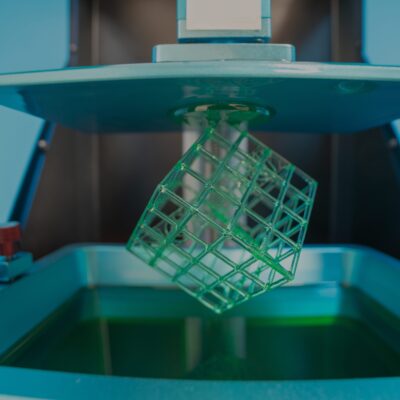

Rapid Prototyping

Our comprehensive portfolio of technologies enables you to produce production-quality prototypes fast. From simple, one-off parts to complex, exacting designs, we invite you to bring it to us. We love a challenge.

Our prototyping capabilities include:

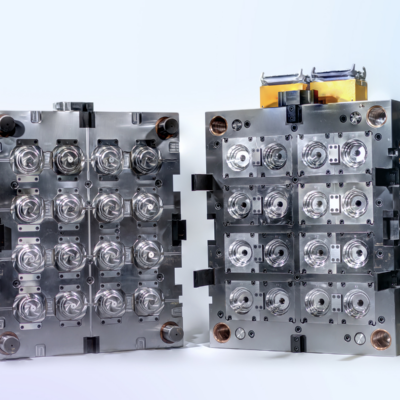

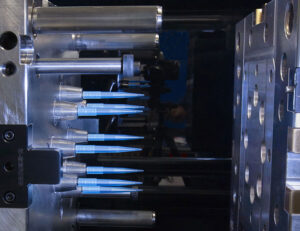

Tooling

High-volume production requires high-quality tooling. Our all-encompassing tooling services ensure we will find the perfect solution for your operation.

Our tooling capabilities include:

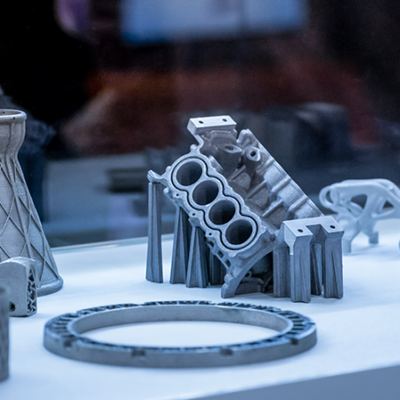

Advanced Manufacturing

Our advanced manufacturing solutions enable us to produce precision parts with complex geometries from a variety of materials. We are capable of manufacturing millions of unique parts to best meet your needs.

Our advanced manufacturing capabilities include:

Supportive Injection Molding

With 15+ injection molding plants globally, our expertise ranges from functional mold testing (FMT) and validation to short-run production.

Our supportive injection molding capabilities include:

Reliability Services

SyBridge offers world-class preventative maintenance services to support your tooling reliability and production uptime. With over 20 facilities worldwide, including five dedicated service locations, we are available where you need us for prompt, reliable and cost-effective repair and maintenance.

Our reliability services include:

Capabilities at a Glance