Making the World of Manufacturing Simple

Accelerate innovation for a faster time to market

High-quality prototyping solutions with speed and agility

Prototyping and production solutions across technologies

Extensive material options and fast lead times

AI-powered instant quotes and design analysis

Get Your Parts Fast

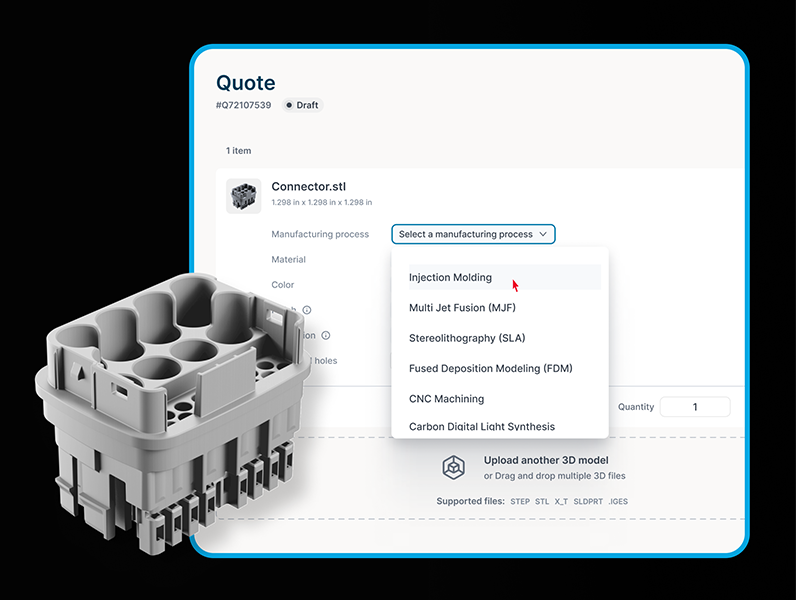

Simplify your manufacturing process in one seamless digital experience with SyBridge On-Demand

An intuitive self-service portal for instant quoting and easy ordering of custom manufactured components. Access a broad range of manufacturing technologies from additive manufacturing to machining and injection molding.

Industry-Leading Capabilities

3D Printing

With six 3D printing technologies and dozens of materials to choose from, you can seamlessly transition from prototyping to full scale production of unique, complex parts and products.

Urethane Casting

Produce parts with high levels of geometric complexity and surface detail without costly post-processing or tooling requirements.

CNC Machining

Achieve the tightest tolerances and select from dozens of plastics and metals to create perfect machined parts with seamless scalability and maximum efficiency.

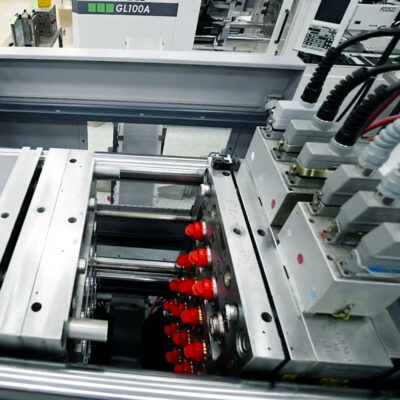

Injection Molding

Manufacture high-quality plastic parts for every stage of the injection molding process, and prepare to scale with bridge to production molding solutions.

Extensive Material Options and Industry-Best Lead Times

SyBridge offers the widest selection of materials across plastics and metals — from advanced polymers and thermoplastics to durable aluminum alloys and various grades of stainless steel. No matter your requirements, we offer materials suitable for your industry or application.

| Technology | Type | Materials | Lead Time | |

|---|---|---|---|---|

| 3D PRINTING | Digital Light Synthesis (DLS) | Rigid: CE 221, EPX 82, EPX 86 FR (Flame Retardant), FPU 50, IND 405, MPU 100 (biocompatible), RPU 70, RPU 130, UMA 90 Non-Rigid: EPU 40, EPU 41, IND 147 - HDT 230, SIL 30 | Typically four business days; expedited orders in as few as two business days | |

| 3D PRINTING | Multi Jet Fusion (MJF) | Standard: Nylon PA-11, Nylon PA-12, PA-12 GF, PP, and TPA Color: CB Nylon PA 12 | Four to five business days depending on material and color | |

| 3D PRINTING | Fused Deposition Modeling (FDM) | ABS-ESD7, ABS-M30, ABS-M30i, Antero840CN03, ASA, Nylon PA-6, Nylon PA-12, Nylon PA-12 CF (Carbon-Filled), PC-10, PC-ABS, PEKK (Antero 800NA), PPSF, ST-130, Ultem 1010, Ultem 9085, Ultem 9085 CG | As few as three business days | |

| 3D PRINTING | Stereolithography (SLA) | Accura 25, Black, Color (multiple), Clear, Durable, Elastic, Flexible 80A, High Temp, Surgical Guide (biocompatible), Rigid 4000, Tough 1500, Tough 2000, White | As few as three business days for prototypes; production or high-volume runs are examined on a case-by-case basis | |

| 3D PRINTING | Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) | Aluminum (AlSi10), Inconel 625, Inconel 718, Maraging Steel, Titanium (Ti64) | Custom quotes available on a case-by-case basis; lead times vary | |

| CNC MACHINING | Plastic: ABS, Acetal (Delrin), Nylon 6, Nylon 30%GF, HDPE, PEEK, PC, PTFE (Teflon), PVC, UHMW Metal: Aluminum (2024, 6061, 6082, 7050, 7075), Stainless Steel (303, 304, 316, 17-4, 420), Other Steel (Mild Steel, Alloy Steel, Tool Steel), Other Metals (Brass, Copper, Titanium) | Eight to 10 business days for orders of <50 parts | ||

| INJECTION MOLDING | Most Common: ABS, PC, PE, PP Other Supported Materials: HDPE, LDPE, Nylon (PA 6, PA 11, PA 12, PA 66), PC/ABS, PEEK, PEI, PET, PMMA/Acrylic, POM (Acetal/Delrin), PS, PSU, PU, TPE, TPU, TPV Additives and Fibers: Colorants, flame retardants, glass fibers, plasticizers, UV absorbers | T1 Samples: As little as two weeks Post-T1 Approval: As little as one week for orders of <10,000 parts | ||

| URETHANE CASTING | Shore D (65 D–85 D) | Standard: ABS-like (80D), PC-like (84D), PE-like (65D), PP-like (70D) High-Performance: 12 Sec Burn (78D), ABS-High Impact (78D), High Impact FR (UL-94V0) (85D), Hi Temp (84D), Nylon/Delrin-like (84D)FDA: ABS-like (80D), ABS-High Strength (85D), Hi Impact Class VI (85D)Clear: Optical Clear (80D, water-clear), PC-like (84D, haze/pale yellow) | First Article (FA): As few as three days, depending on part geometry Post-FA Approval: As little as two weeks | |

| URETHANE CASTING | Shore A (15 A–94 A) | Standard Elastomers: 15A–94A High-Performance Elastomers: 15A–90A Water-Clear Elastomers: 45A, 65A, 70A, 90A Silicone: 15A, 25A, 35A, 38A (medical-grade), 40A, 42A, 50A, 53A, 60A, 75A | First Article (FA): As few as three days, depending on part geometry Post-FA Approval: As little as two weeks |

Post-Processing

We offer a complete range of finishing and post-processing options, including:

- Anodizing

- Powder Coating

- Inserts

- Bead Blasting

- Brushing

- Optical Polishing

- Screen Printing

- Laser Engraving

- Heat Treating

- Light Assembly

- Passivating

- Painting

- Plating

- Ultrasonic Welding

We also offer several custom options depending on your part’s geometry and material.