Originally published on fastradius.com on May 25, 2020

Plastic injection molding offers many benefits to engineers. This manufacturing process is fast, versatile, and ideal for producing large quantities of complex parts with a high level of precision. What’s more, injection molding is compatible with recyclable materials and produces minimal scrap material, making it one of the more environmentally friendly manufacturing processes available. Injection-molded parts are strong on their own, but plastic alone may not fit the bill for certain high-performance use-cases requiring fasteners.

That’s where insert molding, heat installation, and ultrasonic installation come in. These processes all entail inserting a metal threaded insert into a molded part to make it stronger and more wear-resistant, but they’re very different techniques. Here is a comprehensive breakdown of insert molding vs. heat and ultrasonic installation, plus key considerations for engineers.

Insert molding

Insert molding is a subset of injection molding that involves molding plastic material around a pre-placed insert. During this process, the insert is placed in the mold cavity while the mold is open. Then, the mold is closed, the plastic material is injected, and a solid part forms around the pre-placed insert. Insert molding has wide-ranging applications in many industries, from aerospace to medical supplies, and is commonly used to create parts used for further assembly.

Insert molding can produce a high-quality bond between the plastic part and the insert. However, it can be a complicated process to create a mold after the fact that is able to accept a threaded insert. Engineers who know they’re going to want an insert in their part can optimize their design with this in mind and avoid time-consuming modifications.

Heat installation

In contrast to insert molding, heat installation is a flexible way of adding threaded inserts that can be done at any time. Heat installation involves preheating the insert and then using a manual or pneumatic press to push it into preformed holes in the plastic. A controlled force and temperature change must be applied to make sure that the surrounding plastic is sufficiently melted before the insert can be installed.

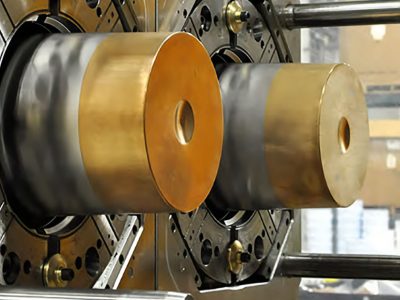

Because the insert must be heated before installation, certain materials and simpler geometries are preferred. The insert material must be highly conductive, like brass or aluminum, enabling it to conduct heat quickly during installation and rapidly cool afterward. Inserts often have knurls designed to grip the mating surface and create strong retention forces. Heat installation, like ultrasonic installation, is best used for prototyping because it’s easy to make changes. For example, if the selected insert is too small, the engineer can simply make the hole a little bigger and start the installation over again. There’s no need to modify the entire tool.

Heat installation has numerous advantages. It’s versatile, reliable, and the use of heat allows the molten thermoplastic to freely flow into retention features. Heat installation is also highly cost-effective. On average, heat installation machines cost 50% less than ultrasonic installation machines. However, heat installation generally requires more time to execute than ultrasonic installation.

Ultrasonic installation

Where heat installation uses a resistive heating element, ultrasonic installation uses high-frequency vibrations to install inserts. This process utilizes a two-pronged approach. While a pneumatic cylinder exerts a downward force on the insert and presses it into the molded hole, an ultrasonic horn turns electrical power into mechanical vibratory output. The horn, made of various metals, such as stainless steel and aluminum alloys, sends vibrations into the insert. The high-frequency vibrations create heat which melts the thermoplastic surrounding the insert.

In addition to the ultrasonic horn, ultrasonic installation also requires a steady source of electricity, cycle controlling timers, and an electrical or mechanical energy transducer. All of these components may sound complex, but ultrasonic installation is actually a very quick and adaptable process. Ultrasonic machines can be easily modified to accommodate inserts of various sizes, shapes, and complex geometries.

Cycle times vary according to insert size, but this process is generally fast for inserts less than ¼” OD. What’s more, ultrasonic installation is safer than heat installation since extreme heat isn’t involved. Ultrasonic installation has the same or better consistency as heat installation, but it’s typically more expensive.

Get started with insert molding

Since up to 75% of an insert’s performance depends on how well it was installed, it’s critical that engineers and product managers weigh all relevant considerations to ensure they make the best decision for their project. Engineers should consider using insert molding if they know their design will require an insert and have accounted for that need from the beginning of production.

Heat installation offers high performance and consistency for a lower price, but ultrasonic installation is faster and often more readily adaptable. It’s easier for engineers to make a measured decision regarding installation methods with the help of a trusted manufacturing partner.

At SyBridge, we’re passionate about helping innovators bring their visions to life through additive and traditional manufacturing methods. We offer strategic advice regarding the best installation method for your insert molded part, as well as end-to-end support throughout the manufacturing lifecycle — from design and prototyping to fulfillment. Contact us today if you’re ready to get started.