HP Multi Jet Fusion (MJF) 3D printing service

What is HP Multi Jet Fusion (MJF)?

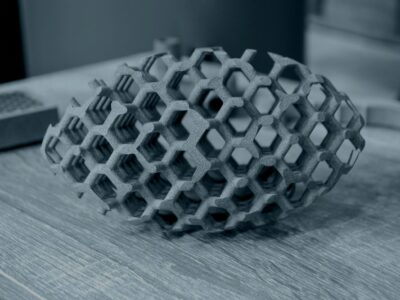

HP Multi Jet Fusion (MJF) is capable of generating functional prototypes and end-use parts with complex geometries and complex assemblies. Parts can be printed in full color, allowing designers to test the aesthetics of a product without the lead times or costs of post-processing. MJF can also produce chemically-resistant and highly dense parts, making it ideal for watertight applications and enclosures.

HP MJF 3D printing is a powder bed fusion process that creates strong parts with high dimensional accuracy. Because MJF doesn’t require support structures, the process allows more design freedom than many other 3D printing processes.

| Technology | Materials | Lead Time |

|---|---|---|

| Digital Light Synthesis (DLS) | Rigid: CE 221, EPX 82, EPX 86 FR (Flame Retardant), FPU 50, IND 405, MPU 100 (biocompatible), RPU 70, RPU 130, UMA 90 Non-Rigid: EPU 40, EPU 41, IND 147 - HDT 230, SIL 30 | Typically four business days; expedited orders in as few as two business days |

| Multi Jet Fusion (MJF) | Standard: Nylon PA-11, Nylon PA-12, PA-12 GF, PP, and TPA Color: CB Nylon PA 12 | Four to five business days depending on material and color |

| Fused Deposition Modeling (FDM) | ABS-ESD7, ABS-M30, ABS-M30i, Antero 800NA (PEKK), Antero840CN03 (PEKK), ASA, Nylon PA-6, Nylon PA-12, Nylon PA-12 CF (Carbon-Filled), PC-10, PC-ABS, PC-ISO, PPSF, ST-130, Ultem 1010, Ultem 9085, Ultem 9085 CG | As few as three business days |

| Stereolithography (SLA) | Accura 25, Black, Color (multiple), Clear, Durable, Elastic, Flexible 80A, High Temp, Surgical Guide (biocompatible), Rigid 4000, Tough 1500, Tough 2000, White | As few as three business days for prototypes; production or high-volume runs are examined on a case-by-case basis |

| Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) | Aluminum (AlSi10), Inconel 625, Inconel 718, Maraging Steel, Titanium (Ti64) | Custom quotes available on a case-by-case basis; lead times vary |

HP MJF Applications

MJF parts have high tensile strength and sufficient resolution for many end-use applications.

- Complex assemblies

Consolidate several parts into one. - Functional prototyping

Durable prototypes suitable for testing in real-world conditions. - Chemical-resistant parts

Resistance to oils, greases, aliphatic hydrocarbons, and alkalies. - Housings, fixtures, tooling, connectors

Ideal for applications requiring high stiffness. - High-volume production runs

3D Printing Guidebook