Originally published on fastradius.com on July 7, 2022

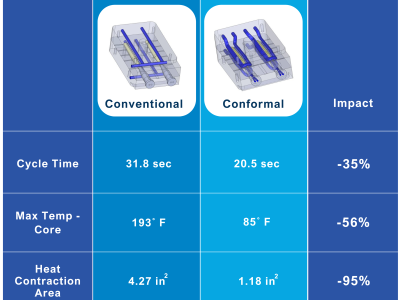

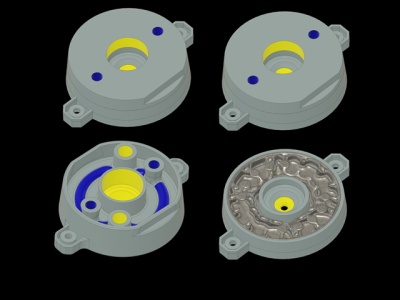

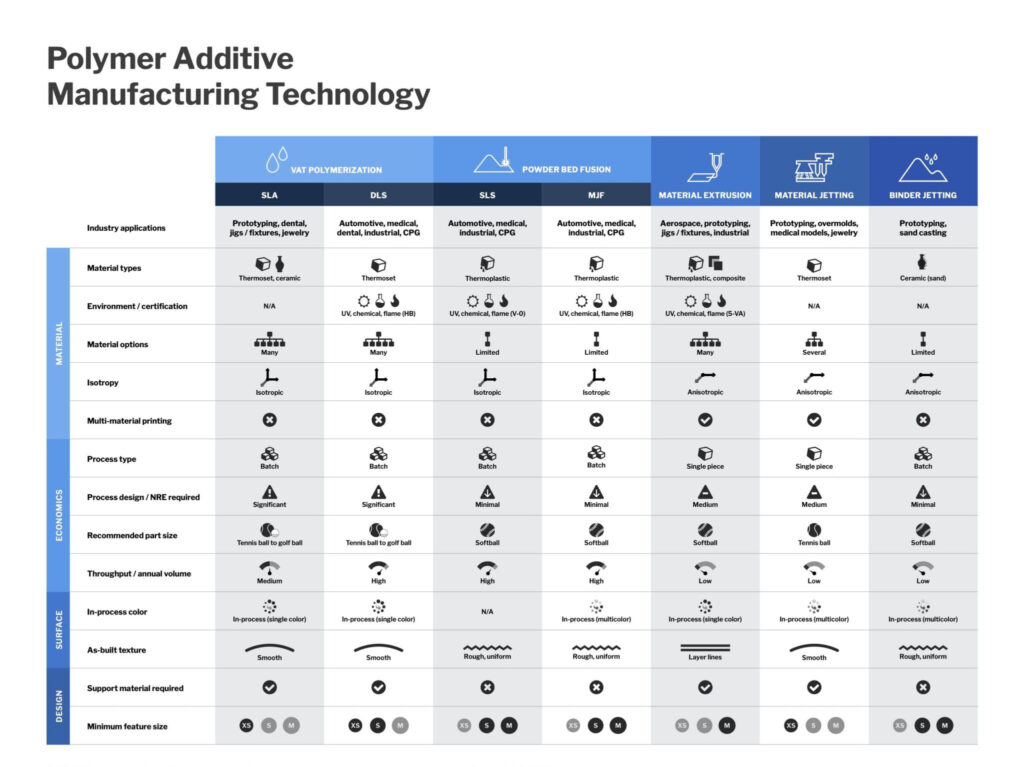

Each additive manufacturing technology has its own unique capabilities and its own set of strengths. To help you better understand each of these technologies and what sort of products and parts they’re best suited for, we’ve drawn upon the knowledge of our engineers to create these comprehensive, easy-to-read charts.

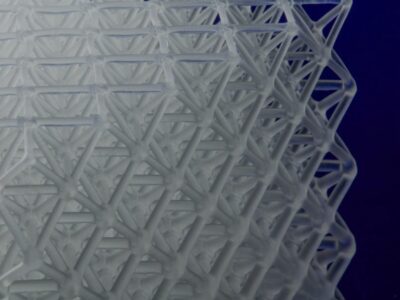

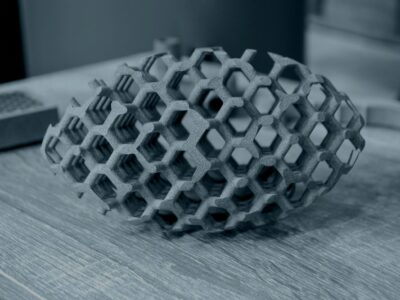

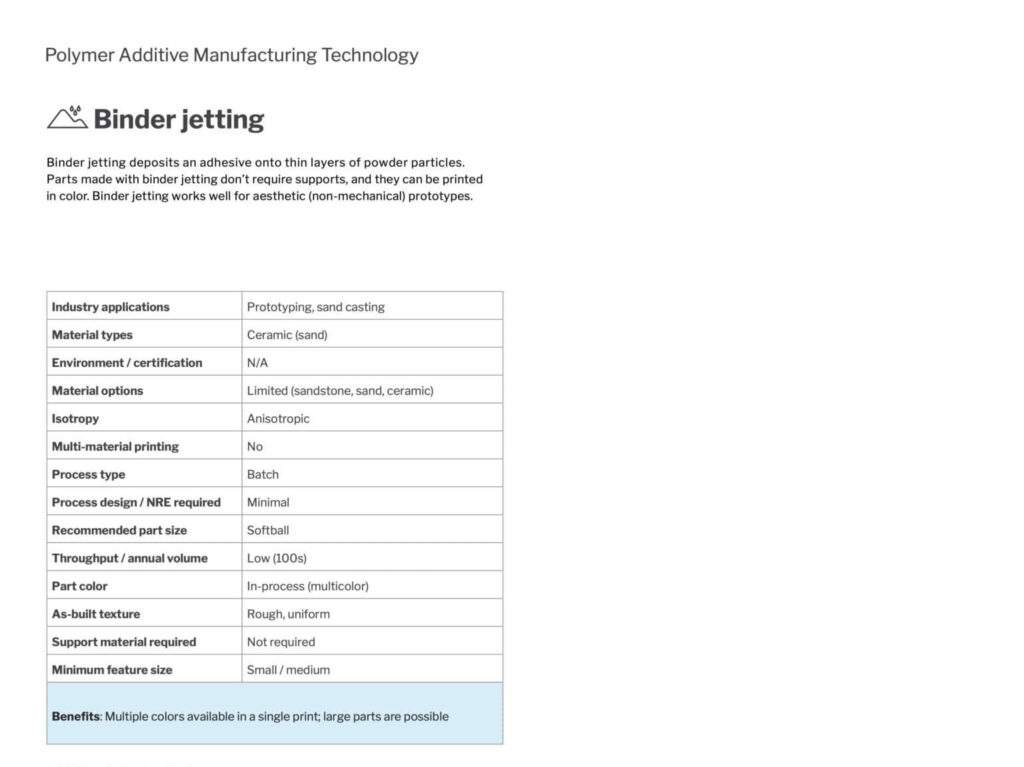

As you look at these charts, you’ll find information about the capabilities of vat polymerization technologies, including stereolithography (SLA) and Carbon® Digital Light Synthesis™; powder bed fusion technologies, including selective laser sintering (SLS) and HP Multi Jet Fusion (MJF); material extrusion; material jetting; and binder jetting.

Looking for more details about specific additive technologies? Keep scrolling.

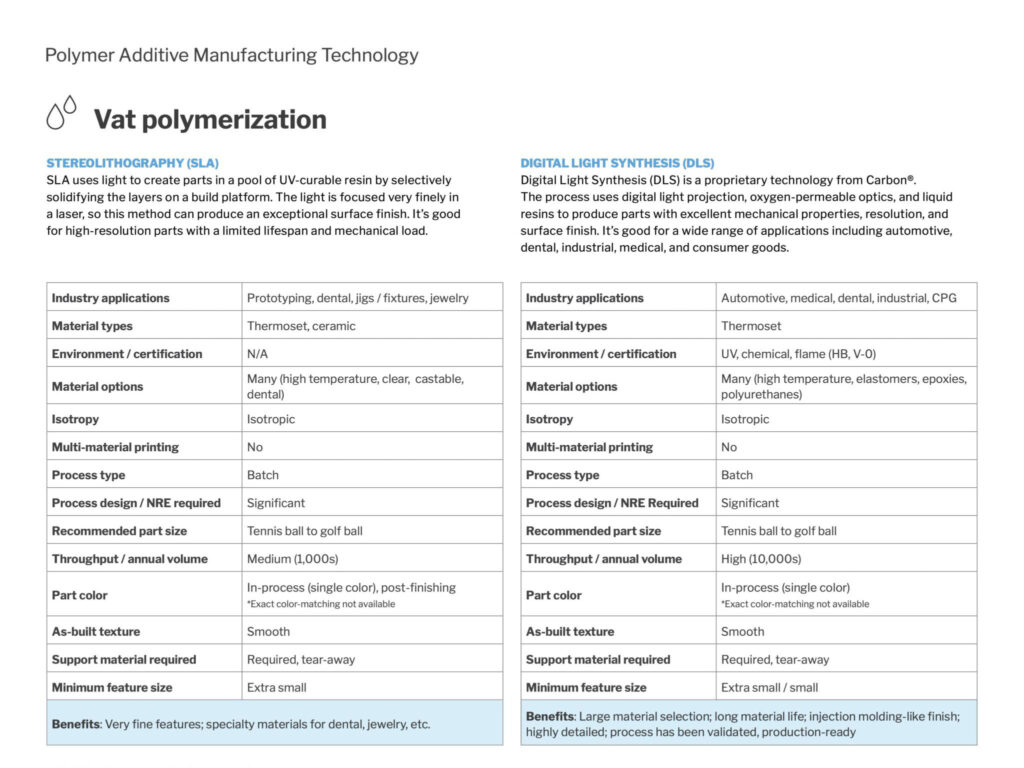

Vat polymerization: Stereolithography (SLA) and Carbon® Digital Light Synthesis™ (DLS)

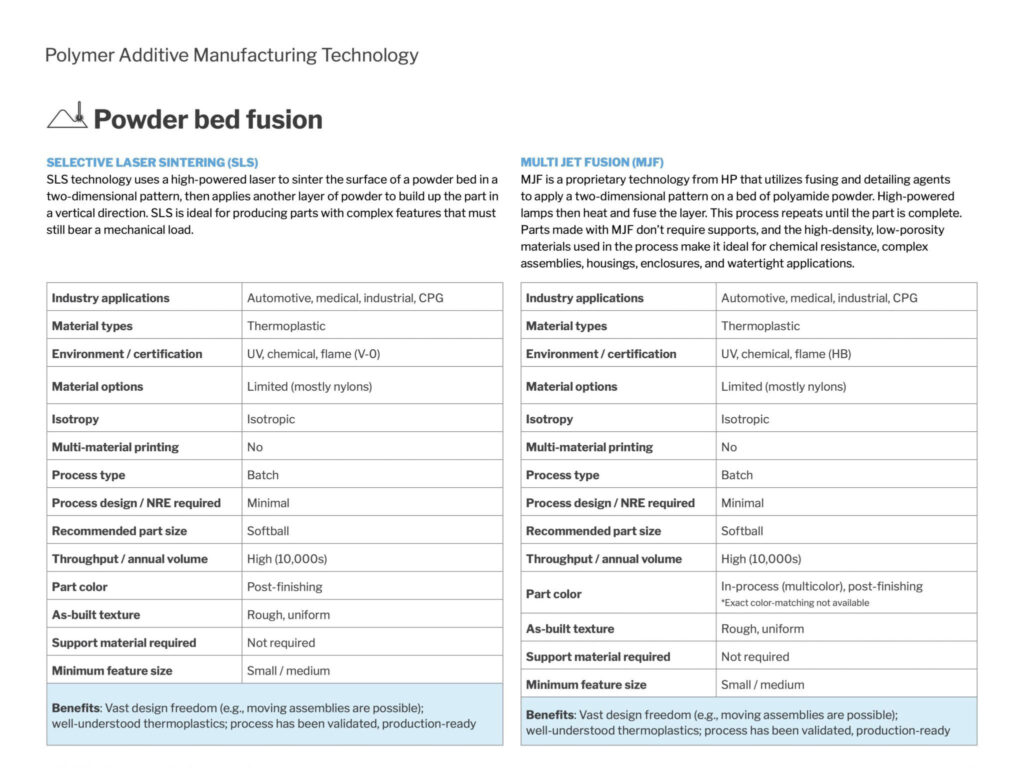

Powder bed fusion: Selective laser sintering (SLS) and HP Multi Jet Fusion (MJF)

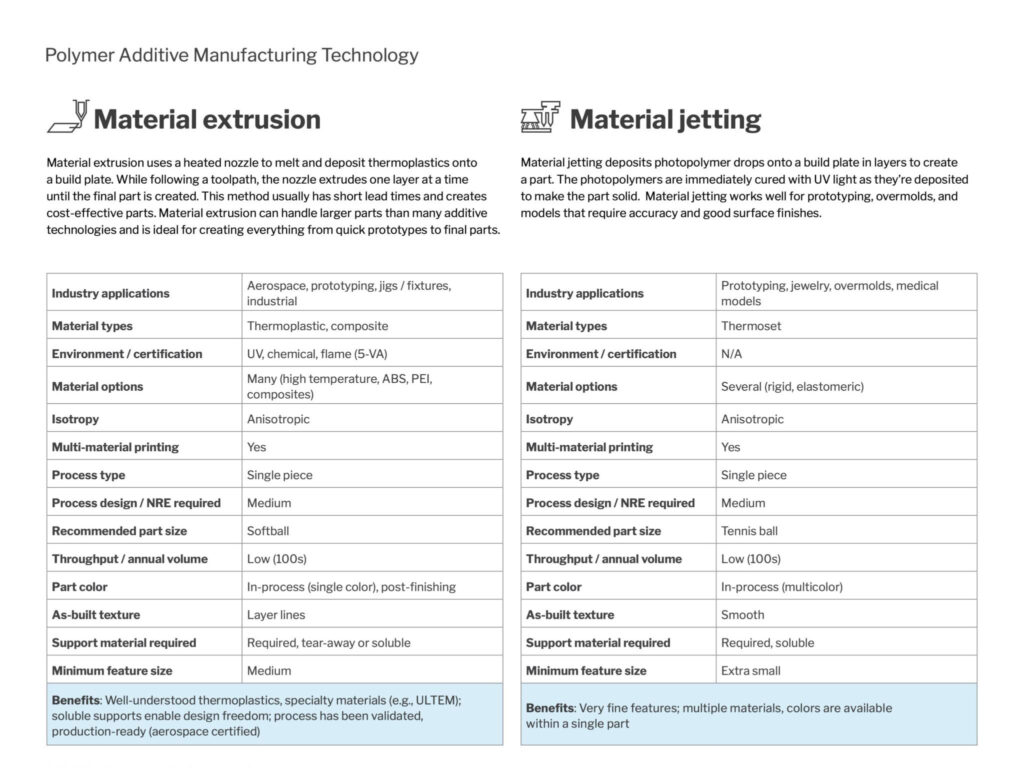

Material extrusion, material jetting, and binder jetting

As always, if you have any questions or are unsure about which additive technology is best for your product and budget, contact us. We’ll guide you in the right direction. You can also compare manufacturability, costs, and lead times for additive technologies by logging in to your SyBridge Technologies account.