Previously published on fastradius.com on November 5, 2019

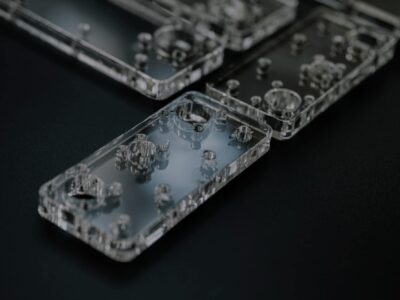

Silicone 30 (SIL 30), is an additive material specifically developed by Carbon® for its Digital Light Synthesis (DLS) process. This silicone urethane offers a unique combination of biocompatibility, low durometer, and tear resistance. Applications that require comfort for skin contact are perfect use cases for SIL 30. SIL 30 is comparable to thermoplastic elastomers with a Shore A hardness of 35.

Mechanical Specifications

SIL 30 is soft to the touch and allows the ability to print customized parts – especially wearables. It’s a specialty material that is only available for specific production applications. Below we have broken down some of SIL 30’s key mechanical specifications:

- Ultimate tensile strength: 3.2 MPa

- Elongation at break: 330%

- Tear strength: 6 kN/m

- Durometer: 35, Shore A

Read the Carbon SIL 30 technical data sheet for more information.

Why SIL?

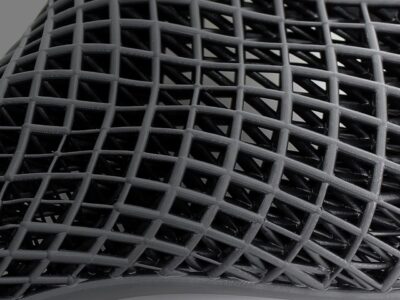

Design tools created specifically for silicon elastomers allow us to tune the performance of SIL 30 through lattice design, allowing it to meet unique requirements in a wide range of applications. SIL 30 prints as a rigid green-state material, only becoming flexible and elastomeric after fully curing. This is important because it allows for better “printability” than other elastomeric materials and enables engineers to produce a wide variety of geometries.

Popular Applications

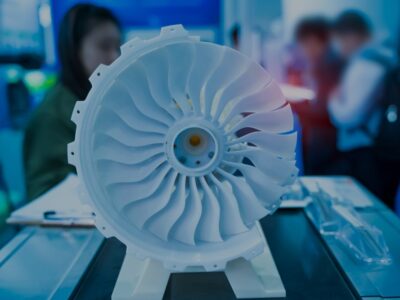

SIL 30’s biocompatibility, tear resistance, and softness make it an ideal candidate for comfortable skin-contact applications such as headphone pads, bike handles, and wristbands. At SyBridge, we’ve had success using this material for grommets, small industrial bellows, and cushioning/foam replacement.

Getting Started With SIL

If you’re interested in learning more about SIL 30, including lead times and design considerations, contact us today.