Originally published on fastradius.com on March 1, 2021

Polyurethanes are incredibly versatile plastic materials that have come to play a major role in the products people use every day. Polyurethanes were invented in 1937 by Dr. Otto Bayer and primarily used as replacements for rubber during World War II. By the 1950s and 60s, polyurethanes were being used in elastomers, adhesives, and flexible cushioning foams.

Today, this material is so ubiquitous that it can be found in almost any product in any major industry. Common applications include leather garments, thermal insulation systems, spoilers in cars, surgical drapes, and much more.

How is it possible that polyurethanes can take so many vastly different forms? It all comes down to the polyurethane chemical formula. Here’s what engineers and product teams should know about the different kinds of polyurethanes, why polyurethane formulation matters, and how formulation can impact their final parts.

Polyether vs. polyester — what’s the difference?

Most commonly polyurethanes are derived from polyethers and polyesters. Both have elastic properties, both can be made to any hardness, and both have a variety of applications across industries. However, polyether and polyester are not interchangeable. Engineers should familiarize themselves with the key differences between these two materials to ensure they’re choosing the best-fit polyurethane plastic for their application.

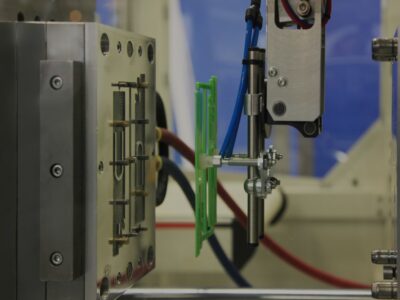

Polyester-polyurethanes are used in softer urethanes (below 90A durometer) and are known for their strong cut-, abrasion-, tear-, and solvent-resistance. They can withstand higher temperatures longer than polyether-polyurethanes and have higher tensile strength. Polyester is also an excellent choice for shock absorption and widely used in applications requiring vibration dampening. Popular applications include banking equipment rollers, bumper pads, and automation clamps.

However, polyester does have its drawbacks. The material generally has poor moisture-resistance and is not recommended for parts that will be exposed to water or high-humidity environments. Hydrolysis will break down the physical properties of the material.

Polyether-polyurethanes, on the other hand, are used in harder urethanes (above 90A durometer) and tend to offer greater moisture-resistance and more dynamic properties than polyester-polyurethanes. This material also has better rebound, better low-temperature flexibility, and performs better in high-speed applications. Its excellent mechanical properties also make it well-suited for parts that will experience medium to high stress.

Popular applications of polyether include skate wheels, elevator wheels, sheet metal forming rollers, and a variety of food-safe applications. Even though polyether is used in harder urethanes, this material actually offers less abrasion-resistance than polyester and is more likely to tear. It also generally comes at a higher price tag.

Why polyurethane formulation matters

To understand why polyurethane formulation is so important, it’s helpful to understand the basics of polyurethane chemistry. Polyurethanes are created through a chemical reaction between a polyol and an isocyanate, which creates a pre-polymer. That pre-polymer is then cross-linked with a curative to form polyurethane. This polyurethane chemical formula might seem simple, but there’s a lot of room for complexity and variability.

Take thermoset polyurethanes as an example. Typically, these kinds of polyurethanes are made up of TDI or MDI backbones — which respectively offer good mechanical properties at high and low temperatures — combined with either ether or ester chemical bonds. Ester-polyurethanes include two oxygen atoms and two carbon atoms, while ether-polyurethanes include only one oxygen atom and two carbon atoms.

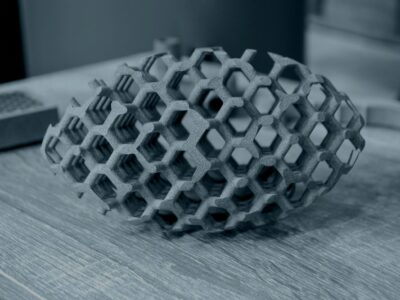

Each unique combination of these backbones and chemical bonds will give the resulting material different physical properties. There are also dozens of chemicals that can be used for curatives in polyurethanes, plus the possibility of blending curatives and additives to create something totally new.

With all of these factors in play, it’s possible to create a seemingly infinite variety of formulations by making small adjustments to the polyurethane chemical formula. That’s why engineers and product teams must evaluate all aspects of their prospective polyurethane plastic and avoid choosing a material based on one or two criteria.

If two polyurethane bouncy balls have the same hardness but different chemical synthesis, one might fall to the floor while the other might spring back up. To make sure a final part performs exactly as it should, engineers and product teams must take polyurethane formulation into careful consideration during the product development process.

Let SyBridge be your polyurethane formulation guide

To sum it up, polyester polyurethanes are better-suited for lower durometer formulations, high-temperature applications, and parts that require shock or vibration absorption. Polyether polyurethanes are better for higher durometer formulations, high-speed or high-stress applications, and parts that will be exposed to water.

Product teams and engineers must evaluate the unique chemical formulations of any prospective polyurethane to ensure their final parts have their desired properties and meet all critical requirements. Working with an experienced manufacturing partner can help.

SyBridge Technologies can help product teams unpack all of the complexities of polyurethane formulation so they can select the right polyurethane plastic for their specific use case. Our talented team of designers, advisors, and engineers know how important material selection is, and can help get a project started the right way. Contact us today to get started and learn more about the services we offer.