Our Specialty Manufacturing Services

Fast, Flexible, and Scalable

Parts Production

SyBridge offers two primary manufacturing services: production-level 3D printing and quick-turn molded parts. No matter the project, you’ll work directly with our expert engineers and local program management to ensure precision and speed at every stage. Explore each service below to see how we can help you bring products to market faster, more efficiently, and with uncompromising quality.

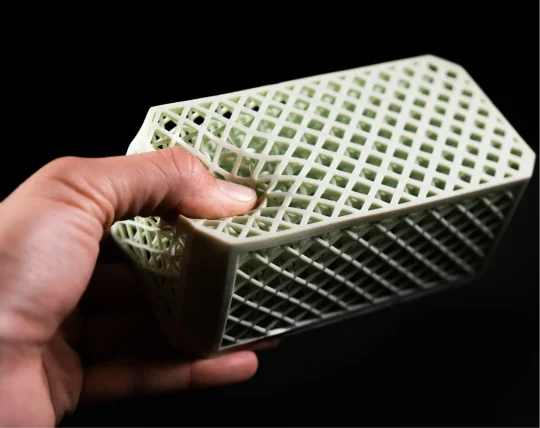

3D Printing

Learn how SyBridge is your perfect partner for high-volume additive manufacturing. With one of North America’s fastest-growing 3D printing production facilities, we’re trusted by leading companies to deliver high-quality, end-use parts at scale.

Explore 3D Printing

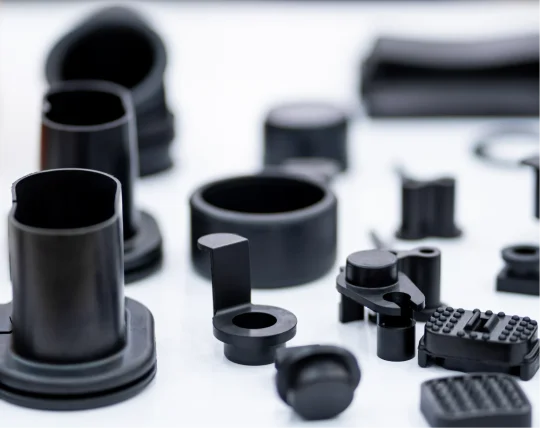

Quick Turn Production

SyBridge can help you drastically compress your product development cycles with quick-turn injection molded parts, ideal for design validation and bridging production gaps to meet your delivery and production requirements.

Discover Quick Turn Production

FAQs

We primarily serve the healthcare, packaging, consumer products, mobility, and industrial sectors, supporting companies that need precision, speed, and scalable solutions.

We offer a wide range of advanced polymer materials suitable for end-use parts. Our production-grade 3D printing technologies include Carbon® Digital Light Synthesis (DLS), HP Multi Jet Fusion™ (MJF), and Stratasys Fused Deposition Modeling™ (FDM)—all optimized for quality and repeatable performance.

Turnaround depends on part complexity and size, but we typically deliver high-quality, functional plastic parts within 2–4 weeks from approved drawings.

Yes. Our 3D printing and quick-turn molding capabilities support small runs through high-volume production, providing a seamless path from prototype to market-ready parts.