HP Multi Jet Fusion (MJF) 3D printing service

What is HP Multi Jet Fusion (MJF)?

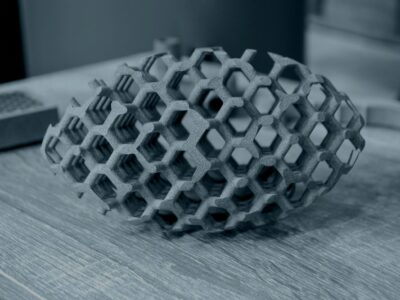

HP Multi Jet Fusion (MJF) is capable of generating functional prototypes and end-use parts with complex geometries and complex assemblies. Parts can be printed in full color, allowing designers to test the aesthetics of a product without the lead times or costs of post-processing. MJF can also produce chemically-resistant and highly dense parts, making it ideal for watertight applications and enclosures.

HP MJF 3D printing is a powder bed fusion process that creates strong parts with high dimensional accuracy. Because MJF doesn’t require support structures, the process allows more design freedom than many other 3D printing processes.

HP MJF Applications

MJF parts have high tensile strength and sufficient resolution for many end-use applications.

- Complex assemblies

Consolidate several parts into one. - Functional prototyping

Durable prototypes suitable for testing in real-world conditions. - Chemical-resistant parts

Resistance to oils, greases, aliphatic hydrocarbons, and alkalies. - Housings, fixtures, tooling, connectors

Ideal for applications requiring high stiffness. - High-volume production runs

3D Printing Guidebook