Originally published on fastradius.com on June 29, 2020

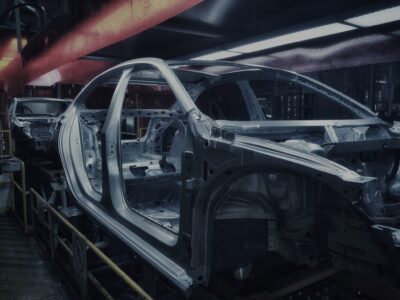

As concerns over driver safety and fuel economy have become more prominent, automotive manufacturers have sought to make all aspects of the vehicle production lifecycle more efficient. Part of this ongoing optimization process includes thoroughly considering the material properties that are most effective or beneficial in automotive applications, and attempting to incorporate more materials that provide these desired characteristics. One key breakthrough in this area has been the development of advanced high-strength steels (AHSS).

Advanced high-strength steels are new generations of steel grades that offer a unique combination of durability, ease of manufacturability, and high strength to weight ratio that ensures steel parts and components meet critical safety and efficiency regulations in a cost-effective manner.

Automakers have been using advanced high-strength steels for years, and as manufacturing processes have improved, so too has each subsequent generation of steels. Using precise heating and cooling processes and different strengthening mechanisms, engineers can achieve optimum mechanical properties — such as high ductility or tensile strength — while also meeting requirements for crash performance, ductility, fatigue, stiffness, and other characteristics.

The various types of advanced high-strength sheet steels provide different properties, as well, which allows manufacturers to tailor their part composition to meet the specific needs of each application. Automobile frames, for instance, require greater stiffness (to maintain the structural integrity of the vehicle) than the parts used in the crumple zone, which are designed to undergo controlled deformations that help protect passengers if a collision occurs.

Types of advanced high-strength steels

Steels that have yield strength levels of 550 megapascal pressure units (MPa) or higher are typically considered to be advanced high-strength steels. For the first and second generation of these metals, engineers were quick to leverage the differences in chemical composition and multiphase microstructures of specific steels to meet the performance demands of automotive components.

- Dual Phase (DP) steel: One of the most widely used advanced high-strength steels and is exceptionally ductile and resists fractures, which allows it to be used in a range of automotive applications, including in structural components.

- Transformation-Induced Plasticity (TRIP) steels: Exhibit high malleability, which gives TRIP steel parts a high endurance capacity. Both provide high energy absorption, which makes them well suited for crumple zones.

- Martensitic steels: Have a microstructure that features increased carbon content, which boosts the strength and hardness of the material but doesn’t increase the weight of components in the same way that a conventional steel part would. Martensitic steels resist permanent deformation, which makes them an excellent material choice for fortifying automotive passenger compartments or safety cages.

New research and developments in the past few years have led to the new, third generation of advanced high-strength steels, which are designed to provide increased combinations of strength and ductility, often at significantly lower costs. While the industry is still working toward a standardized definition of third generation high-strength steels, the typical desired properties are a minimum strength of 1200 MPa and a ductility of 30% elongation — a notable increase over earlier generations of steels.

The applications of advanced high-strength steels

While they’ve been used for years for automotive applications, advanced high-strength steels have also been increasingly incorporated into other manufacturing sectors. The crash safety features of high-strength steels make them ideal for applications in rail transport systems, for instance.

Advanced high-strength steels have also been found to improve engine performance and speed limitations not only for automobiles, but also for aircraft, ships, and trains. The advanced high-strength steel market is also poised to offer significant energy savings to manufacturers worldwide as methods become more efficient.

Challenges of advanced high-strength steels

Advanced high-strength steels do come with some limitations. The increased ductility of third generation advanced high-strength steels requires increasing the alloying content of the metal. This allows the steels to be cold formed into more complex shapes while still retaining material ductility, but leads to increased wear on forming dies and increased springback.

Weldability also presents a challenge, as the microstructures created by higher carbon and alloying content of advanced high-strength steels can be negatively impacted by the rapid heating and cooling involved in the welding process.

One goal in the ongoing development of third generation advanced high-strength steels is to reduce the alloying content of high-strength steels in order to keep costs lower, while also maximizing strength and ductility and avoiding embrittlement.

The manufacturing partnership that redefines what’s possible

Advanced high-strength steels may be well-suited to improve the tensile strength and durability of a variety of parts across industries. Advances in energy efficiency and engineering are likely to make the next generation of advanced high-strength steels even more versatile.

SyBridge is the manufacturing partner of choice if you’re looking to manufacture parts using advanced high-strength steels. Our dedicated team of designers and engineers provides on-demand manufacturing services with comprehensive support throughout the product development and manufacturing lifecycles. We work closely with each of our customers to ensure that every part is optimized for design and manufacturability, using the right processes and techniques to create consistently superior products. Contact us today to get started.