Originally published on fastradius.com on July 24, 2020

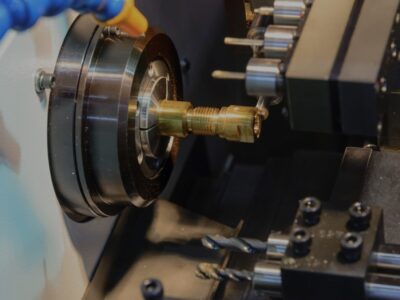

CNC machining is a subtractive manufacturing method that uses tools and rotation to create parts from solid blocks of material. Parts can be machined in a number of different ways, which makes CNC machining a versatile manufacturing process that can be used to create everything from automobile chassis to surgical equipment.

Heat treatments are a technique that have been developed to either make metals more workable during the manufacturing process or to improve the material characteristics after machining has been completed. Applying heat and other elements to metal parts in strategic ways enables the creation of parts with superior ductility, hardness, toughness, and other properties.

Here are some of the most common heat treatments for CNC-machined metal parts.

Annealing

The annealing process involves heating metals to a critical temperature, which varies by alloy, maintaining that temperature for a period of time, and then slowly air cooling the metal to create the desired microstructure within the metal.

Annealing is typically applied to metal alloys after forming to increase the ductility of the material, which makes harder metals less prone to cracking or fracturing during the machining process.

Case hardening

Case hardening is a heat treatment method that increases the hardness of the exterior layer of carbon or alloy steel without hardening the interior material. Metals like iron and steel often have a low carbon content, so applying a combination of heat and a carbon-rich substance to the surface gives an otherwise low-carbon alloy a high-carbon, hardened exterior. This makes case hardening ideal for applications that require flexibility but a durable, wear-resistance outer layer, such as engine camshafts.

While hardening processes provide tremendous improvements to the strength of metals, they also tend to increase the material’s brittleness. For that reason, case hardening is typically performed after machining.

Stress relieving

CNC machining can create stress within part material that, if left untreated, can severely compromise the part’s overall quality. Like annealing, stress relieving involves heating metal alloys to high temperatures and slowly cooling them. However, unlike annealing, this heat treatment is applied after the machining process to remove residual stresses. Stress relieving improves the mechanical properties of a part without changing the material’s structure or hardness.

Quenching and tempering

Also known as martensitic transformation, quenching and tempering is a two-part method specifically designed to increase the hardness of steel parts.

In the quenching process, the steel or steel alloy is heated to a high temperature, which causes the iron’s crystalline structure to change from ferrite to austenite. This allows the metal to absorb more carbon.

The steel is then rapidly cooled to “lock in” the iron phase change, while the addition of carbon results in an extremely strong crystal lattice structure called martensite, which has excellent surface hardness properties.

Tempering, on the other hand, is the process of heating metals to high temperatures (although temperatures much lower than the material’s critical temperature, as opposed to annealing) after the metal has been quenched. This reduces the material’s brittleness, while improving its toughness and prolonging the life of the part.

Precipitation hardening

Precipitation hardening is used to increase the strength of malleable metals like aluminum, stainless steels, and superalloys. The process is similar to quenching and tempering and involves heating metal to a high temperature, quenching it, then heating it to a lower temperature for an elongated period. This allows precipitates in the alloy to disperse and reduce dislocation (irregularity) movement within the microstructure, drastically increasing the strength and hardness of the metal.

Precipitation hardening is commonly applied to components in aerospace applications where reducing weight without sacrificing strength is critical — pieces made from precipitation-hardened aluminum, for instance, can achieve strengths comparable to stainless steel, but at about one-third of the weight.

Choosing the ideal heat treatment process

Heat treatments can deliver incredible improvements to the material properties of metal parts. However, it’s important for product teams to do their research to determine which heat treatment is best-suited for a given part. While quenching and tempering may be ideal for creating high strength steels, it’s a far less useful process for treating aluminum alloys. Luckily, determining which treatment process is right for you is made simpler with the help of a trusted manufacturing partner.

SyBridge believes that going the extra mile should be the norm. We’re a team of engineers and designers who are passionate about making the things we once thought impossible. We bring this drive to each project, providing end-to-end support on projects of all varieties, volumes, and timelines. If you’re ready to find out what superior quality at competitive prices looks like, contact us today.