Originally published on fastradius.com on October 28, 2020

Most consumers don’t think about the surface finishes of their favorite products, but post-processing is top of mind for engineers and product teams. The difference between an inferior product and a superior one often comes down to finishing, and engineers treat parts after manufacturing to achieve certain aesthetic and mechanical properties. For example, sand or bead blasting creates a smooth surface texture that’s very noticeable in softer metals and buffing acrylic improves appearance.

Electroplating, also known as electrodeposition, is a common metal finishing process that uses electricity to coat a part with metal to improve certain properties. Here’s everything you need to know about electroplating, from how it’s done to its most useful applications.

How does electroplating work?

Electroplating using electrical currents to dissolve metal, transform it into a thin layer, and deposit it on to the surface of a part. The electroplating process is comprised of four components — an anode, a cathode or substrate, an electrolytic solution that includes salts and the metal to be plated, and a power source.

First, the anode and cathode are placed in a bath of the electrolytic solution and connected to each other. Then, the power source sends a direct current (DC) of electricity to the anode. The current oxidizes the metal and allows the metal alloys to dissolve into the solution as positive ions. From there, the positive metal ions move over to the negatively charged substrate and settle onto the part as a thin layer of metal over time.

A wide variety of metals and combinations of metal alloys are compatible with electroplating, and each material offers different properties. Engineers often electroplate with copper for added heat resistance, zinc for added corrosion resistance, and nickel for added wear resistance. Careful material selection and requirements evaluation are key to achieving success with electroplating, as certain materials are ill-suited for this finishing option. Product teams must do their due diligence to ensure they’re using the best material for their project.

Although plastic generally doesn’t conduct electricity, it’s possible to electroplate plastic parts if the material is given a few extra treatments. Once plastics like nylon or polycarbonate have been electroplated, they have all the benefits of plastic, but feature a shiny, metallic finish. Plated plastic is also lighter and cheaper than metal, and doesn’t require any polishing in post-processing, making it an ideal choice for some product teams.

Outside of material considerations, there are a number of other factors that can impact the success of electroplating, including solution conditions, part placement, and electrical current. The temperature and chemical composition of the electrolyte bath can impact the effectiveness of electroplating, and so can the voltage of the electrical current. The placement of the anode relative to the cathode also matters — the distance that the dissolved metal must travel will impact how well the substrate is plated. Product teams should be sure to account for these factors.

Advantages and disadvantages of electroplating

The primary benefits of electroplating can be broken down into three broad categories — aesthetics, protection, and conductivity. This finishing process is a cost-effective way to improve the surface appearance of a substrate by coating it with an aesthetically pleasing material. Costume jewelry is an excellent example — manufacturers can use electroplating to coat a cheaper metal like pewter in a thin layer of gold or silver to offer the luxurious appearance of precious metals at a fraction of the cost.

Electroplating places a protective barrier around the substrate that protects the part from environmental wear, which adds hardness, corrosion-resistance, heat-resistance, and thickness.

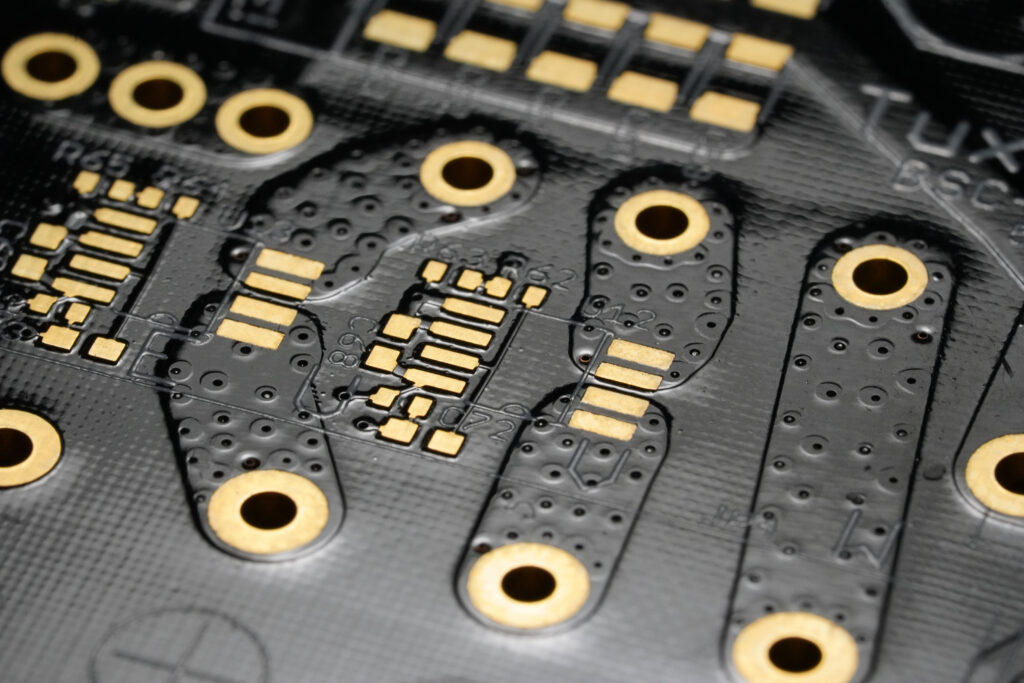

What’s more, electroplating offers a cost-effective and efficient conductivity solution. Gold and silver are excellent electrical conductors, but they’re prohibitively expensive for many product teams. However, coating a part in just a thin layer of these materials via electroplating is enough to offer superior conductivity to electrical components and integrated circuits.

On the downside, electroplating is relatively time-consuming and does not provide the most uniform finish. Also, if the electroplating solution is not disposed of properly, it can become an environmental hazard, so pollution is a concern.

Common applications for electroplating

These limitations notwithstanding, electroplating is a versatile finishing process that’s applicable to a wide range of industries. Electroplating is very common in medical device manufacturing because many devices contain nickel, but nickel cannot come into contact with the body. To work around this and improve biocompatibility, engineers often plate with palladium or gold. This process also improves catalytic converter performance in the automotive industry and improves the conductivity of circuits, making it well-suited for a variety of applications in the semiconductor industry.

Getting started with electroplating

Engineers should consider electroplating if they want to protect their part from heat, corrosion, wear, and other environmental factors, or give their part an attractive, decorative finish. As always, it’s important for product teams to do their research and make sure they’re considering all of the factors at hand — cost, aesthetics, function, and other relevant project-specific requirements — when selecting a post-processing or finishing option.

A trusted on-demand manufacturing partner like SyBridge Technologies makes choosing the right finishing process much easier. Our team of seasoned engineers and designers is well-versed in traditional and additive manufacturing, and we’ll help you bring your ideas to life with clean, functional, well-designed parts. Partner with SyBridge Technologies for end-to-end support that delivers superior results. Contact us today.