Originally published on fastradius.com on October 7, 2020

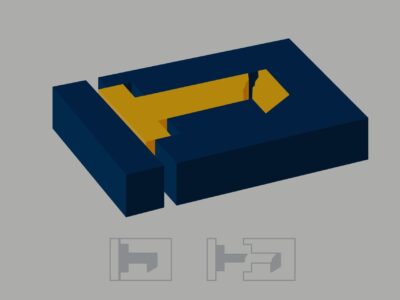

In manufacturing, an undercut refers to a recessed surface, groove, or overhanging feature that inhibits a part from being removed from an injection mold without damage, as seen below.

To understand why undercuts occur, it’s necessary to understand what an injection mold is and how it works. Typically, an injection mold is composed of two halves. Those halves come together and are filled with a molten material, which cools and hardens. Then, the cooled material is ejected from the mold, ideally resulting in a usable part.

Unfortunately, not all injection-molded parts follow this clear process — further design optimization is often required, and undercuts are one of the most common and troublesome problems. In most cases, it’s advantageous — and cost-effective — to eliminate potential undercuts during the design phase. Undercuts lead to added costs, greater complexity, and molds with greater maintenance requirements.

In some cases, those hooks, indentations, or grooves are essential elements of a part’s design. When that occurs, there are several ways to facilitate smooth part ejection and thus injection molding success.

Design solutions for undercuts

While there are numerous design solutions for undercuts, each has different applications, benefits, and drawbacks. Some of the most common solutions include slides or holes. You can also optimize the manufacturability of a part with undercuts by orienting it in the mold so that there are as few undercuts impeding the ejection of the part as possible.

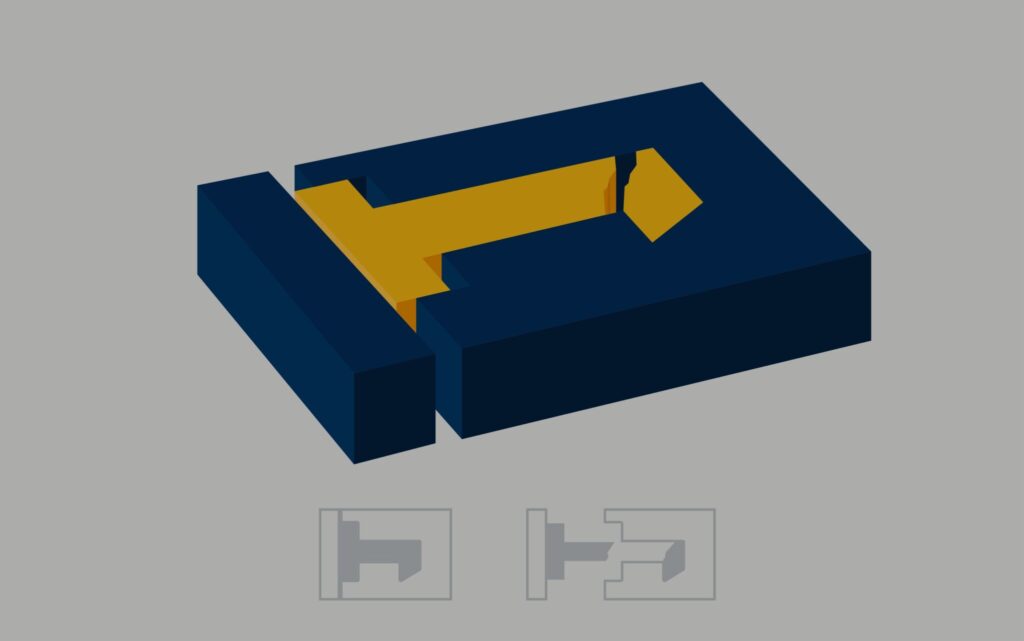

Slides, also called actions, are small pieces that can be removed from the injection tool for easier part ejection. When the slide is removed, the two halves of the mold separate, resulting in the ejection of the part from the mold. Unfortunately, because slides have to be carefully custom-made to accommodate any potential undercuts, they can be a very expensive and complex solution.

Fortunately, they’re not the only option for avoiding undercuts. A more simple and less costly solution is to design features that are parallel to the draw line, or the axis on which the injection mold separates. This enables the injection mold to open and the part to safely eject without damage to its features, thereby avoiding an undercut.

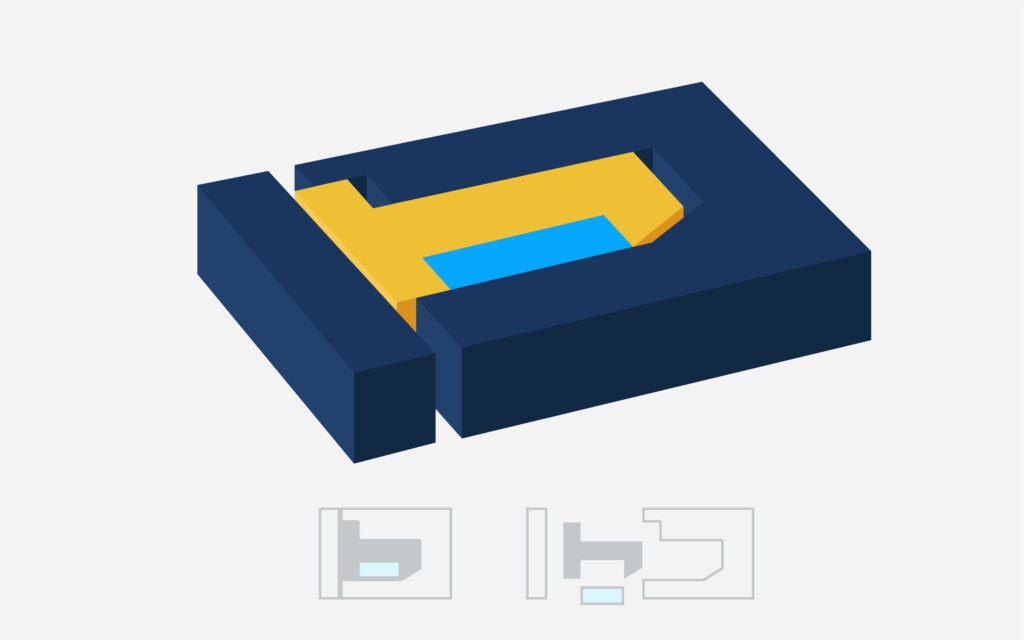

It’s also possible to create a hole or slot in the mold through which the part will eject without hooking or otherwise sticking in the mold. This allows for the metal in the mold to pass through the hole of the part and properly form the underside of the undercut. Of course, if a part needs to be watertight or has certain aesthetic restrictions, slides will be necessary. However, it’s always possible to avoid an undercut — it’s just a matter of selecting the correct workaround for the given part.

Avoiding undercuts with the help of an expert partner

All of these solutions require anticipating and addressing a potential undercut early on, which is why it’s vital for product teams to be aware of what causes undercuts and how they can be avoided with smart and intentional design. That’s where SyBridge comes in.

The SyBridge team of expert engineers works alongside product teams of all shapes and sizes to ensure that undercuts aren’t an obstacle to polished, functional final products. Whether the part requires a hook, indentation, or groove — or can be redesigned to omit those features — our team of experts are prepared to optimize the design and deliver superior results at speed. Contact us today to learn more.