Originally published on fastradius.com on August 31, 2020

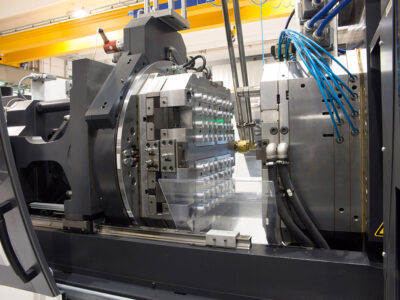

Tooling, or machine tooling, refers to the process of building the different types of components and machinery necessary for manufacturing. Tooling can be broken down into two broad categories — soft and hard.

Soft tooling is a cost-effective approach to tooling that’s ideal for low-volume production runs. Many manufacturers use soft tooling for prototyping and creating test units because this process boasts short lead times and fast order turnarounds. Plus, it’s compatible with a wide variety of materials. However, soft tools tend to wear out quickly, so they don’t make sense for higher-volume production.

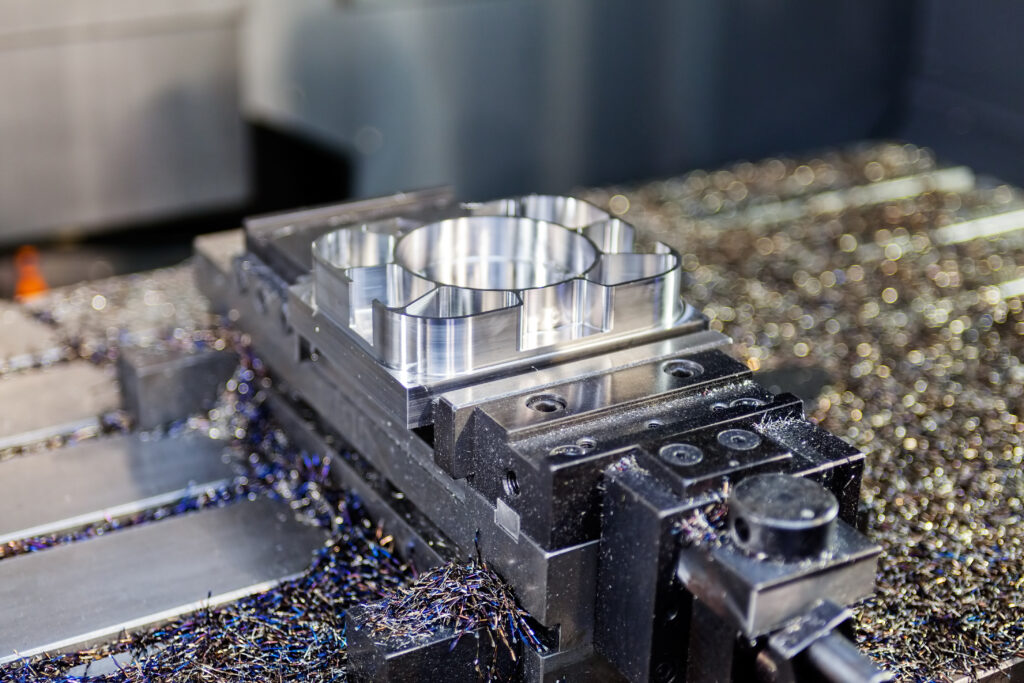

Hard tooling, on the other hand, is the preferred tooling method for high-volume production runs. Hard tools are more expensive than soft tools, but they’re built to last and pay for themselves over time. The metal they are manufactured from is literally harder, yielding a more robust and resilient mold that can make millions of parts with high precision and accuracy. Aluminum and steel are the most commonly used materials for soft and hard tooling, respectively, and they both bring unique benefits to the injection molding process.

Here are the key differences between aluminum and steel tooling, plus when to use one over the other.

Why Material Choice Matters

For engineers and product teams, choosing the right material for their tools is just as important as choosing the right material for the overall project. A well-made tool made from the right material makes for a smooth manufacturing process.

Engineers should consider production size and production speed first because these factors are key considerations in determining appropriate tooling materials. After that, engineers can begin to think about specific qualities they want in their tool, such as wear resistance or the ability to accommodate complex designs. Once material options have been whittled down, engineers should choose the material that satisfies the maximum number of criteria for the lowest possible cost.

The Case for Steel Tooling

When it comes to durability, steel tooling outpaces aluminum tooling by a wide margin. Steel offers superior strength and is able to withstand years of repeated use, making it the best choice for high-volume production runs. A well-designed, well-maintained steel tool can produce millions of parts without breaking down. As such, cost-per-part decreases as quantity increases.

Steel’s strength also allows designers to explore a wider range of applications and get creative. When a part requires complex, extremely small or precise features — features like non-uniform walls or narrow mold cavities that would normally push the boundaries of injection mold design best practices — steel molds yield better results. This material is better able to retain its shape in the presence of complex geometries.

Also, steel can be used with advanced resins that are reinforced with glass, fiber, or other additives. Softer metals like aluminum are more susceptible to scratches and erosion from the additives, which can negatively affect the tool’s surface finish.

The most significant drawback to steel tooling is cost — steel molds generally require high upfront costs. Also, steel molds take up to seven times longer to heat and cool than aluminum molds, which extends cycle times.

The Case for Aluminum Tooling

Steel is durable, but aluminum offers other valuable advantages. Aluminum tooling is more cost-effective than steel tooling for many reasons. First of all, initial investment costs are lower — aluminum molds typically cost around $1,500 — and engineers will get better value for low-volume production runs. Also, since this material is ideal for simple mold designs, engineers can also save on manufacturing time and costs. In 15 days or less, engineers can build the aluminum mold and complete their production run.

Aluminum tooling also gives engineers more options than steel when it comes to manufacturing. Steel molds are notoriously difficult to modify or repair because the material is so strong, and, for bigger design changes, engineers often have to start over with an entirely new mold if production errors have occurred. Aluminum is softer and easier to repair, plus its superior heat dissipation reduces the number of parts rejected due to shrink, warp, and sink marks.

Aluminum tooling does have its limitations, however. Aluminum isn’t as durable as steel and molds tend to wear out after a few thousand production cycles. This can cause nonconformities in the part that must be retooled, which drives up costs. Another point to note is that, when tooling with aluminum, texture selection is fairly limited due to the material’s low density.

Tackle Tooling With SyBridge

Engineers should consider steel tooling if they need to manufacture at least 50,000 highly detailed parts and have the funds to invest in expensive molds that they’ll use for the foreseeable future. Aluminum tooling is worth considering for low-volume production and for those looking for a quicker, more cost-effective alternative to steel. As always, product teams should spend some time researching tooling materials to ensure they’re making the best decision for their project.

An experienced manufacturing partner like SyBridge can help engineers and product teams weigh their options and choose the best tooling method for their production run. Our team of expert technologists, engineers, and designers are prepared to streamline the product development process — from ideation and prototyping to post-production and fulfillment, faster than you thought possible. Contact us today for a quote.