Originally published on fastradius.com on March 3, 2021

Two-shot injection molding is a dual-step manufacturing process that enables the rapid production of complex, functional parts from different materials in a highly efficient way.

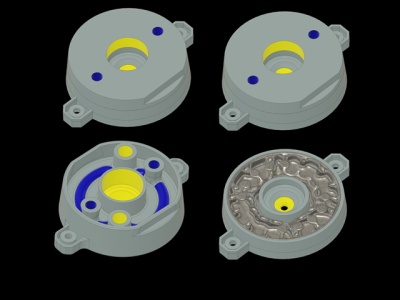

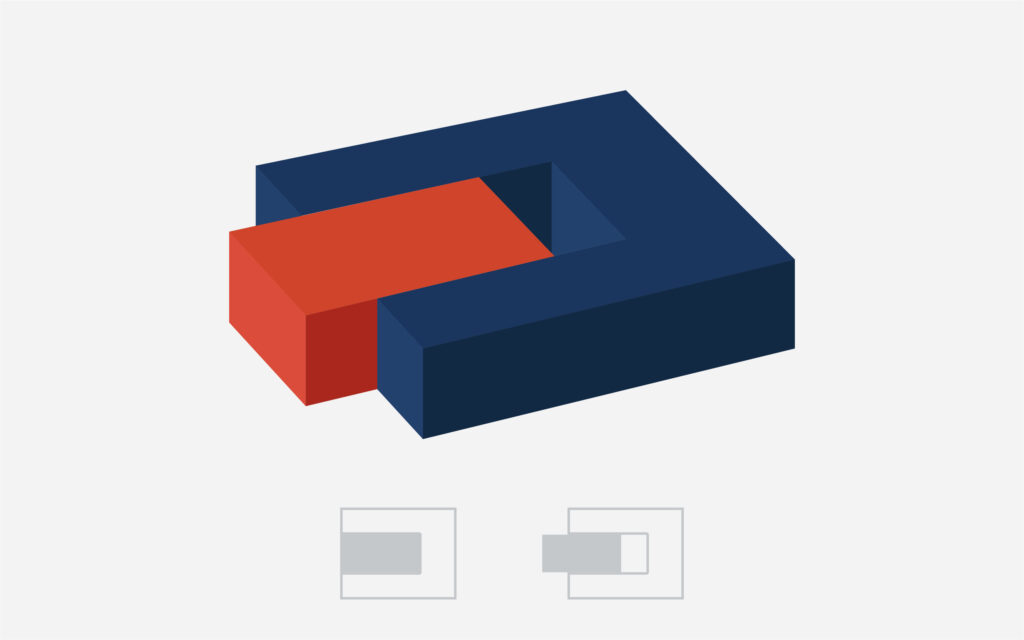

The first step of the two-shot injection molding process is similar enough to traditional injection molding: heated resin is injected into a properly warmed mold. However, the two-shot injection molding process incorporates an additional, subsequent step: the freshly molded part is quickly transferred to a second mold, becoming the substrate onto which the second shot is injected.

Chemical bonds form between the two different thermoplastic resins as the part cools (the substrate will still be warm during the second shot, which can actually increase the strength of these bonds). When the part has cooled, it can be ejected.

The transfer between molds is typically performed by a rotary platen, robotic arm, slide, or some other form of specialized equipment — which makes two-shot molding a process with fairly steep startup costs. However, once set up, the process is largely automated, which makes two-shot molding especially cost-effective for high-volume part production.

Whether you just need a quick refresher or you’re entirely new to the world of injection molding, here are the basics of two-shot injection molding.

The many applications of two-shot injection molding

Two-shot plastic injection molding is used to create products for industries ranging from consumer goods and automotive parts to medical components and electronics. Many of these products require acoustic or vibration dampening of some sort and/or feature multi-color or multi-material apparatuses, rigid parts with soft grips, flexible hinges, or movable segments. Two-shot molding can also be used in tandem with insert molding to add multiple plastic layers to a metal insert.

Two-shot molding is often used to create non-slip surfaces and ergonomic grips that make products from power tools to phone cases easier, safer, and more comfortable to hold. The overmolded material in the second shot typically has greater elastomeric properties than the substrate, which also makes the process useful for molding seals and shock absorbers directly onto products.

The benefits of two-shot injection molding

Don’t let the initial upfront cost of two-shot injection molding scare you — that expense is generally offset by cost-savings in a number of key areas, namely part consolidation, production efficiency, and improved part quality. A great quantity of parts amortized over the tooling cost can also be negligible when considering the overall costs of two-shot injection molding.

Two-shot plastic injection molding helps keep the number of pieces within a given product assembly to a minimum. Optimizing your mold and part designs to reduce component totals can result in savings of tens of thousands of dollars in development, prototyping, and testing for each piece consolidated.

Two-shot injection molding allows you to use a single tool to fabricate multiple components. The machines that use a rotary platen, for instance, rotate the substrate 180 degrees as it is transferred into the second mold, which frees up the first mold to create an additional substrate while the second mold fills. Because this process is highly automated, operational costs and labor remain low. Not only that; two-shot molding also helps to reduce (if not entirely eliminate) the need for assembly, welding, or additional post-production processing.

Two-shot molding also enables greater design flexibility — including the ability to design more geometrically complex parts (which may not be able to be created through assembly and other means) — while reducing scrap rates in the process. Finally, because two-shot injection-molded parts are created with the same tool, you might find that your tolerances can be a little looser without sacrificing part accuracy or repeatability of production.

Important material considerations for two-shot injection molding

When properly utilized, both two-shot injection molding and overmolding take advantage of the chemical bonds that form between the materials as the part cools. However, the two materials must be compatible in order for these bonds to form. Two-shot molding material compatibility refers to how stable the two materials are when they come in contact — if contact causes a chemical reaction, however mild, the two materials cannot be used together.

Another factor to consider is the sequence of the two shots. In general, the more rigid of the two materials should be injected first, forming the substrate for the second material. In other words, if the material with the higher melting temperature is not injected first, the second shot risks deforming the entire part. If a component involves both opaque and transparent materials, then the transparent materials should be injected first for this reason as well. Further, each material’s shrinkage rate also needs to be taken into account, as uneven shrinkage can lead to flash or warp during production and cooling.

Other design considerations for two-shot injection molding

Draft angles are critical in injection molding — and especially important in two-shot injection molding, as the substrate must be able to move rapidly from the first mold to the second without sticking.

Additionally, when rotation is involved, the design of the production machinery also needs to be taken into account — the second gate should be located next to the ejection system to ensure product quality. Finally, it’s worth noting that a sealing effect can be created by injecting slightly more material than is necessary with the first shot and pressing the substrate tighter (through the use of a cleverly designed cavity) during the second shot.

Discover the advantages of two-shot injection molding today

While useful, two-shot injection molding is a difficult process to master. The two-shot molding process can be used to create complex, high-quality end use parts and consumer goods — so long as you account for certain design, material, and process variables. However, even the smallest setbacks and errors can be expensive and extend production deadlines. Contact us today to learn more.