Originally published on fastradius.com on October 19, 2020

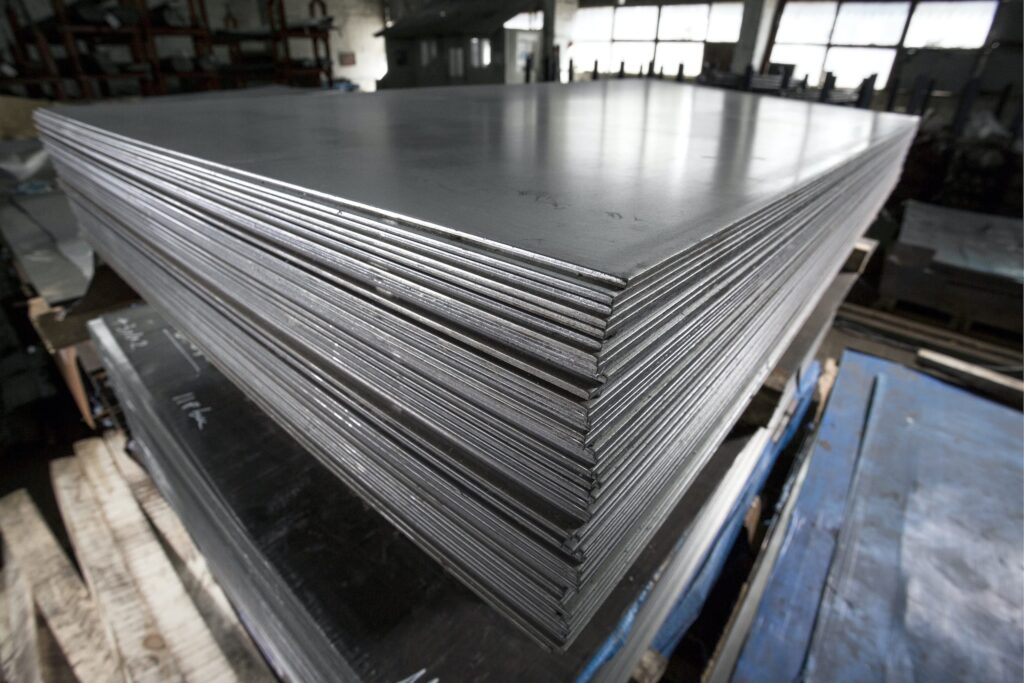

What do RF shields, airplane wings, automobile bodies, roofs, and ductwork have in common? They’re all made from sheet metal. Chiefly defined by its alloy and thickness, sheet metal ranges from 0.006 to 0.25 inches. Beyond these lower and upper bounds, metal is defined respectively as foil and plate. While especially ideal for large, durable parts with few features, sheet metal has many applications because it’s relatively economical and easy to form.

But what goes into creating sheet metal, and what should engineers and product managers consider?

Sheet metal production processes

Because there are a number of ways to manufacture sheet metal, it is a viable form of production for a myriad of projects. Each sheet metal process has its advantages and drawbacks, so manufacturers should choose the process that best suits their intended end use. These are among the most common sheet metal production processes:

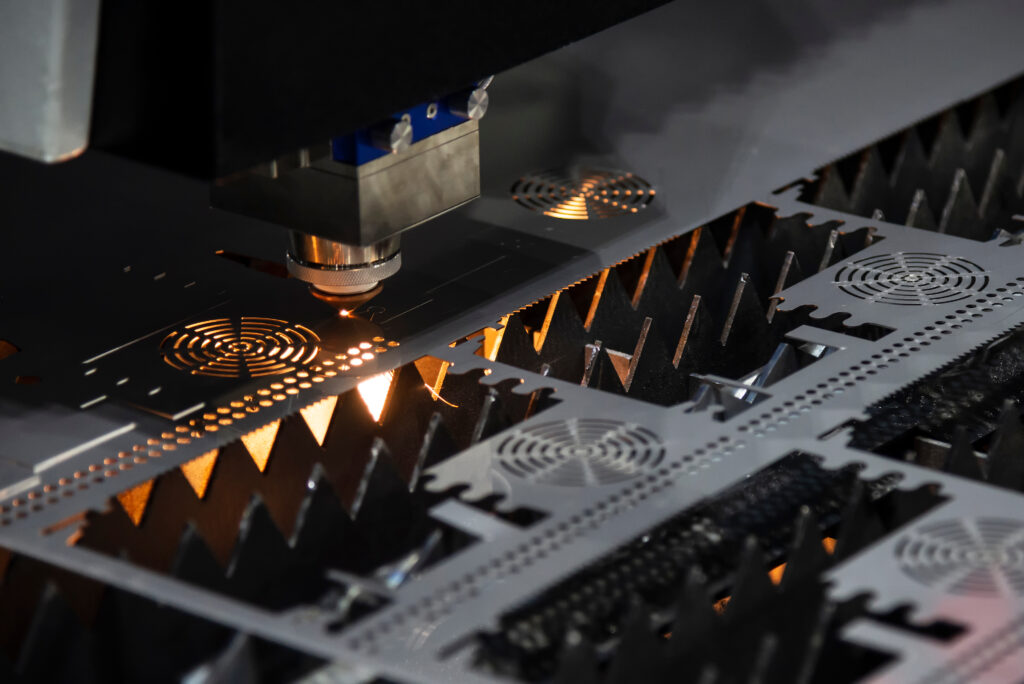

Laser cutting

Prior to the debut of laser cutting in the 1960’s, parts had to be manually milled to the desired shape. Laser cutting enables manufacturers to mass produce parts from sheet metal, drastically cutting down the production time.

Bending

As the most common sheet metal fabrication operation, bending involves the use of a press break to form an angle in a part. By bending sheet metal, manufacturers can exert a high level of control over where bends are located and to what degree they’re bent. However, bending cannot be used to create complex geometries.

Forming

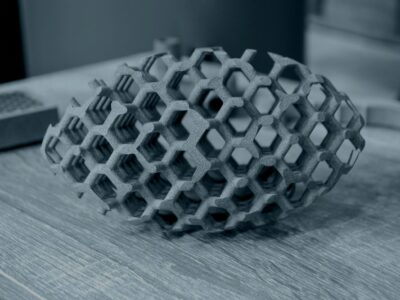

To create complex geometries from sheet metal, manufacturers must turn to forming. Forming enables the addition of a number of small and detailed features, including dimples and louvers. Forming is also a good way to add stiffness to a sheet metal part.

Progressive Forming

Progressive forming takes forming to the next level, allowing teams to add even more complex features to a sheet metal product. Progressive forming also allows for an origami-like approach to shaping the sheet metal, enabling manufacturers to add features in a specific order to achieve the desired final product.

Types of sheet metal

Sheet metal can be made from almost any kind of metal, but the most common materials include aluminum, steel, and brass. Aluminum is by far the most commonly used; it’s affordable, easy to bend and form into shapes, and ideal for creating complex geometries. It’s also favored for its corrosion resistance.

Steel, on the other hand, tends to be more appropriate for high-strength, structural applications. For example, it’s common to see steel used in buildings or in large machinery. Brass is usually reserved for more specialized applications, and particularly electrical applications.

Sheet metal design and production considerations

Because methods of sheet metal manufacturing are neither additive nor subtractive, designing for sheet metal fabrication comes with unique criteria that differ from those of other manufacturing processes.

Because sheet metal maintains consistent thickness throughout the production process, it influences bend radius, or how tight the bends can be and how close they can be to each other. Generally speaking, the thinner the material, the easier it is to form — but at the expense of stiffness.

It’s also important to understand some key sheet metal characteristics. Bending, in particular, can present difficulties for manufacturers, but these concerns are relatively simple to address. Because bending stretches — and thus thins — the metal, features must be placed away from bends to avoid distortion. It’s typically recommended that designers maintain a standard distance of four times the material thickness from the bend.

Sheet metal is one of the most versatile materials available today, but designers, engineers, and product managers looking to leverage sheet metal must consider some of its unique properties and plan accordingly. Contact us today to get started.