Automotive

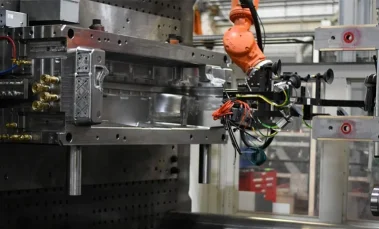

Tooling that Drives

Performance

Delivering reliable, repeatable

results for OEMs and Tier 1s,

from design to road

At SyBridge, we deliver more than just tooling for vehicle components—we apply a proactive, engineering-first mindset to every mobility program. With decades of experience supporting major automotive OEMs and Tier 1 suppliers, our team brings deep technical expertise to complex parts and programs across interiors, exteriors, and structural systems for automotive, powersports, aerospace, and beyond.

Your Full-Lifecycle

Tooling Partner

Mobility manufacturers need partners who can move as fast as the market, without compromising safety, reliability, or quality. SyBridge brings an integrated lifecycle approach—covering design, prototyping, production, and ongoing maintenance—to keep your programs running smoothly and on schedule.

- 7 mobility-focused plants across the U.S., Canada, and Mexico

- IATF 16949:2016 certification at key Windsor, Canada facilities

- Itasca, IL facility uniquely certified to AS9100D and ISO 9001:2015 for aerospace programs

- ISO 9001:2015 certification across all automotive-focused facilities in Canada and Mexico

- 300,000+ sq. ft. of dedicated mobility tooling space

- 50+ designers and engineers focused exclusively on mobility solutions

- End-to-end support: DFM, prototype and bridge tooling, production tooling, fixtures and gauges, tool and part validation, production components, and tool repair services

High-Performance Solutions

Across Mobility Markets

We engineer, build and maintain best-in-class tools for a wide range of mobility applications—delivering durability, repeatability, and compliance for the most demanding programs.

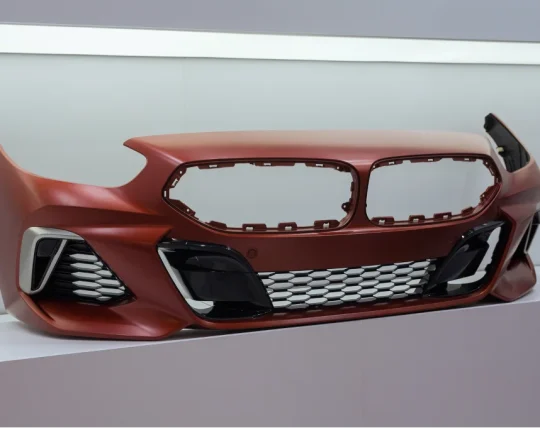

Automotive Exterior Components

SyBridge provides high-durability tooling for painted and Class A exterior automotive parts, engineered for superior fit, finish, and long-term performance. Our solutions meet the demanding requirements of OEMs and Tier 1s, ensuring consistent quality across high-volume runs.

- Air Intake Manifolds

- GOR Brackets / Energy Absorbers

- Headlamp Assemblies

- Chrome Assemblies

- Upper & Lower Fascias

- Wheel Flares

- Wheel Liners

- Side Mirror Housings

- Door Cladding & Accents

- Rocker Assemblies

- Spoilers

- Outer Panels

Automotive Interior Components

Our tooling for interior vehicle components combines precision, tactile quality, and seamless integration to achieve both aesthetics and reliability. We support unpainted interior parts that meet stringent ergonomic and durability standards, including:

- A-B-C-D Pillars

- Cluster Bezels

- Gauge Bezels

- Steering Column Bezels

- Seat Components

- Console Assemblies

- Instrument Panel Assemblies

- Glove Box Assemblies

- Door Assemblies

Other Motor Vehicles

From motorcycles and ATVs to construction and agricultural vehicles, SyBridge provides tooling for specialty and recreational vehicles designed to perform in tough environments.

- Motorcycles

- ATVs

- Agricultural Vehicles

- Heavy Trucks

- Construction Vehicles

- Jet Skis/Watercrafts

- Snowmobiles

Aerospace & Defense

Our aerospace tooling delivers precision and reliability for critical components across aircraft, UAVs/drones, and other platforms. We support complex geometries and tight tolerances to ensure safety, performance, and compliance in both commercial and defense markets.

- Aircraft components

- UAVs and drone assemblies

- Specialty aerospace platforms and systems

FAQs

We build and maintain tooling for both interior and exterior automotive parts, including fascias, bezels, headlamps, spoilers, consoles, instrument panels, and more. We also support specialty vehicles such as ATVs, motorcycles, agricultural equipment, and aerospace platforms.

Both. In addition to world-class tooling, we offer full-service injection molding at several of our Ontario, Canada sites. With 16 presses (225 to 4,000 tons), we can provide bridge production, validation, and high-volume manufacturing, giving OEMs and Tier 1s a single partner for tooling and molding.

IATF 16949:2016 at key Windsor, Canada facilities

AS9100D and ISO 9001:2015 at our Itasca, IL aerospace facility

ISO 9001:2015 across all automotive-focused facilities in Canada and Mexico

These certifications ensure compliance with the

With 300,000+ sq. ft. of dedicated mobility tooling space, over 50 engineers and designers, and global/local program management, we scale with OEM and Tier 1 needs while maintaining speed, quality, and cost efficiency. These certifications ensure compliance with the highest automotive and aerospace standards.