Originally published on fastradius.com on December 3, 2020

Today’s product teams have their pick of countless secondary processes and finishing options when putting the final touches on a new part. However, not all finishing options are made equal, and not all are well-suited for a given application. For example, some finishes provide a part with a desired functional characteristic, while others offer a desired aesthetic; others can provide both.

Common finishing options include brushing, polishing, tumbling, hot stamping, powder coating, electroplating, and anodizing. While some finishing methods are used primarily to improve the aesthetics — such as brushing, hot stamping, or polishing — others may provide functional benefits, like anodizing which improves impact and corrosion resistance.

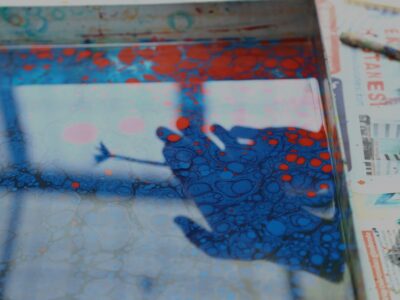

Hydrographics, also known as water transfer printing, immersion printing, or water transfer imaging, is an aesthetic finishing process that involves applying printed designs to parts by placing the substrate in a tank filled with water and a soluble printed film. Though water transfer printing is largely performed for its aesthetic results, it also offers increased chemical- and UV-resistance. What’s more, it can be used on metal, plastic, glass, wood, and more, making it an especially versatile option.

The technology that enables water transfer printing was invented almost 40 years ago; the first US patent for a hydrographic apparatus was granted in 1982. However, it’s only become widely popular in the last couple of decades, particularly in the automotive and sporting goods industries. It’s frequently used to apply decorative trim to vehicle interiors, camouflage patterns to hunting equipment, or eye-catching patterns to products like bike helmets.

Water transfer printing basics

The water transfer printing process consists of several basic steps. Once a pattern has been selected, it’s necessary to apply a base coat to the part. The base coat can have a drastic impact on the final look of the product, so it’s important to select the color of this coat based on the desired pattern. Brown or tan base coats are appropriate for patterns like camouflage, while silver or grey is ideal for most metallics.

With the base coat applied, hydrographic film in the desired pattern should be carefully placed on the surface of the water in a dipping tank. The film will dissolve, leaving only the pattern behind. The pattern will be sprayed with an activator, which dissolves the components in the pattern’s colors without affecting the pattern itself.

Then, it’s time to immerse the part in the water. The surface tension of the water creates pressure that enables the pattern to curve around the object and adhere to it. The part should then be removed, dried, and covered in a clear coat to protect the surface.

Key considerations for water transfer printing

Water transfer printing is highly favored for certain applications because it allows patterns to be transferred onto objects of any shape. For that reason, it’s particularly suitable for transferring patterns onto parts with complex geometries.

Generally speaking, water transfer printing should be successful on any surface that’s mostly non-porous, and many product teams find that water transfer printing allows for a high degree of customization at a reasonable price point.

However, there are several key considerations when it comes to water transfer printing. For one, it may be necessary to automate part of the application process, depending on production run volume, as hydrographic printing can be tedious to perform.

It’s also important to note that the ink films used for water transfer printing are highly sensitive to moisture and temperature, and they must be stored in a controlled environment with humidity below 60% and temperature ranging from 68° to 77°F. Finally, water transfer printing is a delicate process that requires significant training to perfect; as such, some product teams may want to consider outsourcing the process.

Getting started with hydrographics

There are numerous advantages to hydrographics, but it’s a delicate and somewhat finicky process that requires an experienced professional, a controlled storage facility, and depending on volume, some level of automation. For product teams unable or unwilling to invest a substantial amount of time and resources in developing an in-house water transfer printing practice, partnering with a company that is dedicated to hydrographics may be a preferred option.

Countless product teams have worked with SyBridge to create the perfect finish for their parts, regardless of shape, size, and material. In fact, SyBridge works with customers at every step of the manufacturing process — from designing, prototyping, and iterating to post-processing and fulfillment. We ensure that product teams get the best product for the best price. Contact us today.