Originally published on fastradius.com on April 9, 2020

In our latest video, we share how you can use generative design to optimize the shape of your 3D-printed parts.

Transcript:

Generative design is the latest buzzword in engineering, but it’s more than just a fad.

Let’s get into what generative design is and how it works with 3D printing to make better designs.

Generative design is a class of digital tools that optimizes the shape of your part. It combines fast simulations and powerful optimization algorithms to put material only where it’s needed.

The result is a complex, organic looking structure that would be impossible to make without additive manufacturing.

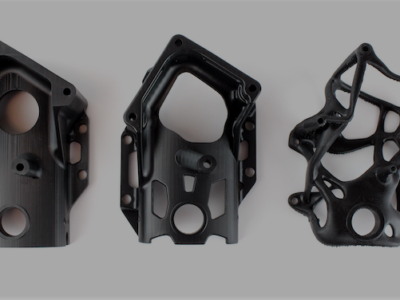

Take this example part designed for machining. Now compare it to its generatively designed equivalent.

Not only does it look really cool, but it’s actually a better part.

And think about using this part on a vehicle — the reduction in weight could save a lot of money on fuel over its lifetime.

There are all kinds of ways to use generative design tools to improve your designs.

Contact us to get started.