Originally published on fastradius.com on March 25, 2021

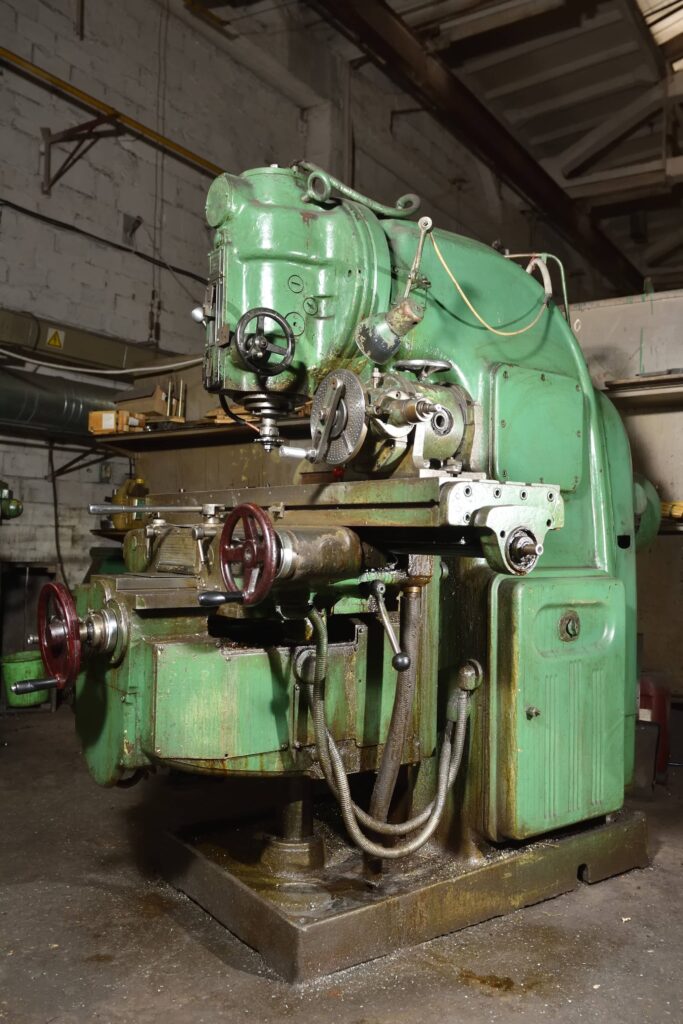

CNC machining is a family of subtractive manufacturing techniques that use computer-controlled processes to fabricate parts by removing material from a larger block. Because each cutting operation is computer controlled, multiple machining stations can manufacture parts from the same design file simultaneously — the result being highly precise end-use parts capable of achieving extremely tight tolerances. CNC machines are also capable of cutting along multiple axes, allowing manufacturers to create complex shapes with relative ease.

The history of CNC machines is rich, and the technology has come a long way since the early days of automation, which used cams or punched paper cards to aid with or direct tool movement. Today, the process is widely used to create complex and intricate medical device components, aerospace parts, elements of performance electric motorcycles, and many other cutting-edge applications. Here’s a quick history of how the technology has developed over time:

The history of CNC: Punched paper cards and the early days of automation

The first known example of a modern machining tool is a boring machine created by industrialist John Wilkinson in 1775, which allowed for steam engine cylinders to be manufactured with far more consistent precision and accuracy. Wilkinson adapted the design for the boring machine from a similar device he’d created for boring cannon tubes.

However, the first technologies to lay the groundwork for modern computing date back to 1725, when textile worker Basile Bouchin created a method of encoding data onto paper tape in the form of punched holes, a technique that Joseph Marie Jacquard improved upon in 1805. Jacquard traded the paper tape for stronger, sturdier cards that were tied together in sequence, which automated how fabric was layered into the loom. This machine became known as the Jacquard loom and was instrumental to the future development of programmed computers and machines.

Punched card technology was put to various uses during the 1800s, and in 1889, inventor Herman Hollerith patented an electromechanical punched card tabulator, which allowed for data to be input — and even stored — with greater efficiency.

A new era: The development of numerical control technologies

The birth of modern numerical control processes is most often attributed to John T. Parsons and Frank L. Stulen, who, in the 1940s, developed a process of feeding airfoil coordinates into a swiss jig borer using punched cards painstakingly crafted to contain up to hundreds of data points. This automated mill, the result of an Air Force research project, enabled manufacturers to create consistent helicopter airfoil components using preprogrammed operations.

In the decades since, the development and incorporation of new, digital technologies into CNC machining processes further increased the method’s efficiency. During the 1960s, computers became smaller and more accessible, leading to their increased popularity in the business sector in following decades.

By the 1980s, the cost of both microprocessors and CNC machines had dropped low enough that small local area networks (LANs) began to spring up, allowing a greater number of manufacturers to take advantage of this versatile process, which had historically been exclusive to universities and large companies, due to the astronomical prices of building computers. This boom ultimately catalyzed the development of the modern manufacturing sector.

Digital manufacturing and future of CNC machining

While CNC machining as a production process involves numerous variables to account for, part of the method’s versatility lies in its fundamental simplicity: a cutting tool removes material from the workpiece; the process repeats until finished.The process has very few limitations when it comes to workpiece material and can achieve extremely tight tolerances, which make it make it an especially advantageous and cost-effective choice for manufacturers seeking to create tooling, niche parts, and metal parts in medium to high volumes.

Recent advancements in monitoring and modeling software have led to the creation of computer-aid manufacturing (CAM) tools that enable designers to test and refine their CNC toolsets and machining operations virtually. Using virtual machine tool pathing to optimize production before physical tools and workpieces get involved can speed cutting times and reduce wear on the cutting tools themselves.

Choosing a manufacturing partner like SyBridge is the surefire way to ensure that any and all CNC-machined parts are designed and produced according to the highest standards. We work closely and transparently with each of our customers, which allows us to show exactly where and how we’re able to save time and expenses without sacrificing quality or performance. Contact us today to learn more.