Originally published on fastradius.com on March 17, 2021

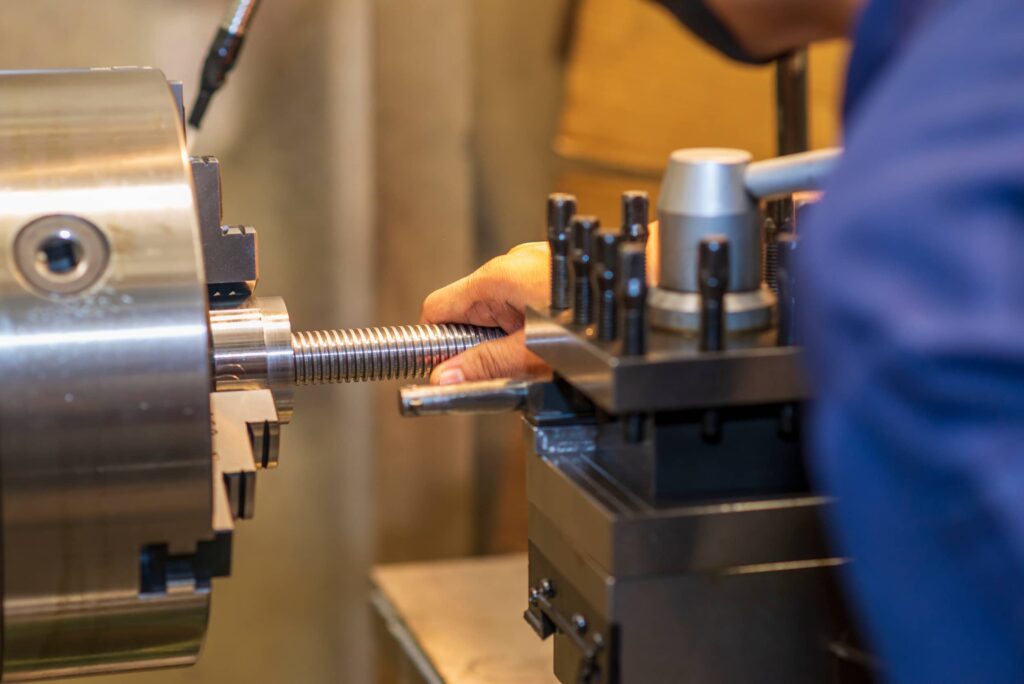

Along with material selection, design is among the most critical factors in determining the quality and functionality of a final part. Regardless of the chosen manufacturing method, product teams should adhere to design for manufacturability (DFM) principles during the design and prototyping phases of any project. However, many product teams find DFM particularly challenging when designing parts for CNC machining.

Although CNC machining is excellent for producing parts with tight tolerances, it is expensive to achieve sharp internal features, especially right angles. CNC bits are round, so if an engineer tries to machine a 90° angle with a round bit, the bit will never be able to cut a right angle. The inaccessible corner geometry left behind is called a corner radius. Inside corner radii directly affect the machinability of a part, and can also impact cost and production timelines.

Luckily, designers and product teams can navigate this problem with a few effective design workarounds for avoiding sharp internal features. If sharp internal features are strictly necessary, there are a number of manufacturing solutions that can be employed. Here’s what product teams need to know.

How to avoid sharp inside corners

A designer’s best bet is to avoid using sharp inside corners altogether and include radii on all internal edges. Machinists will use an end mill with a radius slightly smaller than the radius of the added to the edge. For example, if a part’s radius is 0.25”, then a 6mm or 7/32” end mill should be used. This ensures that the machine can run at a reasonable speed without inducing stress on the tool.

Another option is to use non-standard corner radii. Adding at least 0.02” to 0.05” to the internal corner radii gives the endmill enough space to turn slightly in the corner without coming to a complete stop.

Additionally, designers can soften inside corner radii by creating a rounded toolpath with a larger tool. Larger tooling creates wider inside corner radii and reduces tool engagement, which decreases machining time, cuts costs, and creates a smoother surface finish. 150 percent tool radius is adequate, but 200% tool radius is generally considered ideal.

Machinability workarounds for sharp corners

If a product team is using a design that requires sharp inside corners, they still have a few solutions available to them. Some teams choose to leave the inner corner radii intact, but reduce their size by using a drill bit with a smaller diameter. This is a quick, relatively low-cost approach that does not make the original design more difficult to machine. It should be noted, however, that this approach is not suitable for thicker CNC materials.

The most common way to accommodate sharp corners is to use a dog-bone or t-bone fillet. These fillets are types of undercuts that extend the shape of the corner beyond the cut area so the drill bit can either make a full rotation and leave the corner, creating a 90° angle, or back up slightly to create a sharp corner as it follows the toolpath. Like the names suggest, dog-bone fillets look like chew toys and t-bone fillets look like the letter “T,” with rounded edges.

Dog-bone and t-bone fillets are not difficult to incorporate into CNC designs and they do not inherently drive up CNC machining costs. However, designers must remember to make the entry point for the dog-bone fillet 15% to 20% larger than the router bit diameter.

If the design cannot accommodate a dog-bone fillet, the simplest way to include sharp inside corners is to manually square them off using a pull-saw, standard chisel, or corner chisel. Broaches, shapers, and electrical discharge machining tools can also create sharp corners, but they tend to be less cost-effective solutions.

You can also achieve right angles by using wire EDM. Technically, you won’t be able to achieve a true square corner — there will be a tiny radius of 0.005″-0.006″ left behind by the wire — but many product teams find a radius this small to be acceptable. Machining around sharp corners with wire EDM can provide a very precise cut and an excellent surface finish. However, it’s important to note that wire EDM machines are very slow, especially compared to CNC cutting tools.

Design for machinability with SyBridge

For many product teams, designing a clean, functional part is easy — it’s designing for manufacturability — and machinability specifically — that is more challenging. Optimizing a design for manufacturability takes practice, experience, and a lot of technical expertise. How can product teams be sure that their design will result in a functional, beautiful part that won’t drive up CNC machining costs?

Designing for machinability becomes much easier with the help of an experienced manufacturing partner like SyBridge. We have the latest digital design technologies at our disposal, and our team of design experts and engineers can help product teams of all shapes and sizes optimize their part. Contact us today — let’s make new things possible.