Originally published on fastradius.com on August 9, 2021

The aerospace parts manufacturing industry maintains high quality standards, rigorous testing practices, and strict regulatory requirements in order to ensure the function, fit, and reliability of every part. The aerospace industry uses many specialized parts and, given the nature of flight, many of these parts are mission-critical.

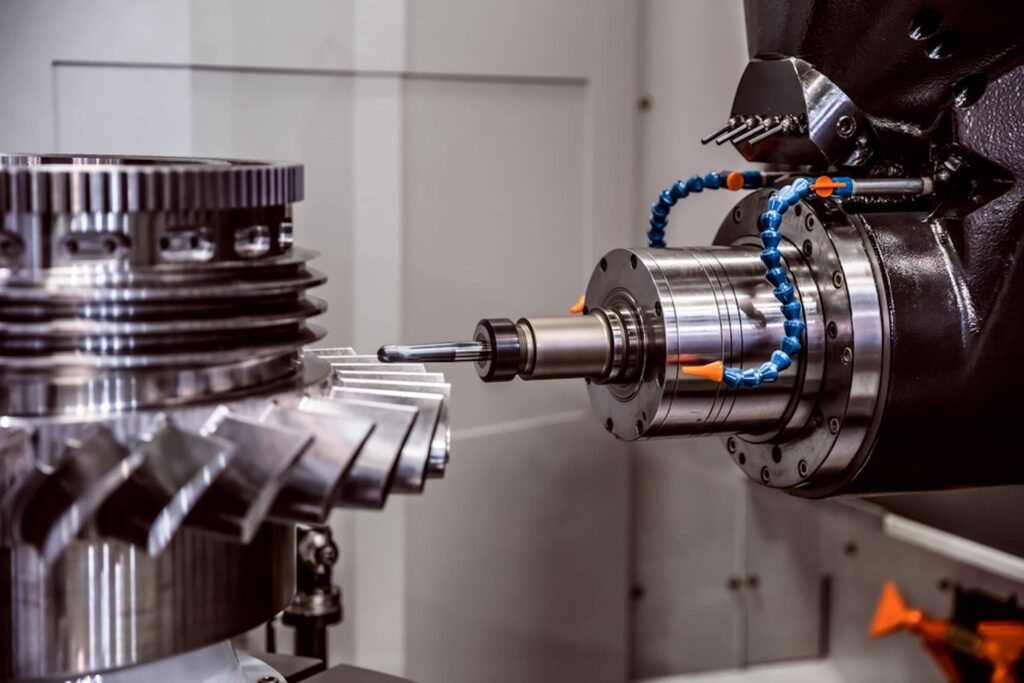

With the many relevant regulatory requirements, testing criteria, and functional requirements at work in modern aerospace manufacturing, part precision is very important. The way aircraft are produced and assembled is precise, so inconsistencies and flaws can have wide-reaching negative effects. CNC machining is a good fit for manufacturing aerospace parts because the process is capable of achieving extremely tight tolerances for both plastic and metal parts. Here’s what you need to know about the key role CNC machining plays in aerospace manufacturing.

CNC machining for aerospace parts manufacturing

To briefly recap, CNC machining is a manufacturing process that uses a combination of high-speed rotation and cutting tools to remove material from a solid workpiece. The cutting operations that shape the part are computer-directed, which allows multiple machine setups to produce the same part at the same time, significantly increasing the speed of production and reducing opportunities for human error. CNC machining produces precision parts on a repeatable basis. This makes machining a go-to process for aerospace parts manufacturing.

5-axis CNC machining, in particular, proves useful in manufacturing complex aircraft components. This aerospace machining process allows for cutting operations and workpieces to be manipulated along the X, Y, Z, and linear axes simultaneously. This reduces the need to reconfigure or fixture the part between operations and makes it possible to create parts with greater complexity.

In the world of aerospace manufacturing, complexity tends to offer a range of benefits, including lightweighting. Parts that are hollowed out or geometrically complex, coupled with the development of advanced, performance-grade engineering plastics, make it possible to dramatically reduce the weight of assemblies without sacrificing strength, quality, or other performance characteristics. 5-axis machining is ideal for addressing the precision, technical specifics, and scope needs associated with aerospace components.

CNC machining applications across sectors

Aviation

Accuracy and precision are critical to building and assembling safe, functional aircraft, and CNC machining plays a key role in producing aerospace manufacturing tools accurately and efficiently. Many aerospace parts — ranging from outer shells and wings to engines and cockpit components — can be machined, which helps guarantee greater degrees of consistency throughout production while minimizing the risk of part failure.

Spaceflight

Even more so than aircraft, spacecraft must be built and assembled with accuracy and precision. There are a couple of reasons for this. First, spacecraft often have to withstand the environs of space for long stretches of time, potentially lasting as long as years. Second, re-entering Earth’s atmosphere is no walk in the park — spacecraft meant to survive reentry cannot be assembled in a casual manner.

Both of these are highly reliant on selecting the right materials during the manufacturing process. In addition, this makes precision and accuracy critical to protect both the crew and all the expensive equipment — that could contain samples, sensor data, or other valuable data — onboard the ship, as well. The design, engineering, manufacturing, and assembly processes all focus on ensuring safety for those on board.

Machining the future of flight with SyBridge

CNC machining is one of the most valuable assets in an aerospace manufacturer’s toolkit.

The SyBridge team of engineers and designers are well equipped to handle metal and plastic CNC machining for aerospace parts, provide guidance on how to improve the strength-to-weight ratios of your components and assemblies, and more. If you’re ready to learn more about what we can do to help get your next project off the ground, contact us today.