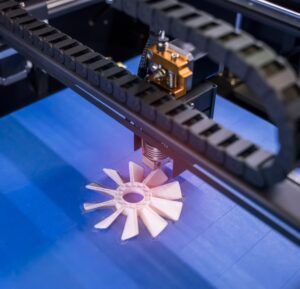

Fused Deposition Modeling (FDM) 3D printing service

What is Fused Deposition Modeling (FDM)?

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is the most common type of 3D printing, and is widely relied on for its ability to produce strong and cost-effective parts. FDM is also suitable for larger build sizes than other additive technologies.

FDM has short lead times for prototypes, a relatively low cost per part, and can produce larger parts than many other additive polymer technologies. With a variety of material choices and finishing options, our FDM 3D printing service is ideal for creating everything from quick prototypes to the final product. Our in-house FDM technologies include the Fortus 450mc and the Fortus 900mc.

FDM Applications

With a variety of material choices and finishing options, FDM 3D printing is ideal for creating everything from quick prototypes to the final product.

- Regulatory requirements

Aerospace, food-grade and automotive applications - Large parts

Larger build size than other additive technologies - Jigs and fixtures

Practical and reliable tooling - Prototypes

Quick turnaround allows for rapid iteration

3D Printing Guidebook