Originally published on fastradius.com on April 12, 2021

Transparency, determined by how much light passes through an object, is often a desirable property in 3D printed parts. Transparency is essential for many consumer goods, such as cosmetics packaging and kitchen products, while clear surgical guides and medical models help healthcare professionals do their jobs safely and effectively.

Here’s what you need to know about clear 3D printing, including tips for maximizing clarity, which translucent materials to use, and common 3D printing technologies.

Key considerations for maximizing transparency

To achieve transparency in a 3D printed part, you must adhere to the following three rules:

- The plastic material you use must be transparent on its own.

- The 3D printing process you select must prevent air bubbles from forming in the part.

- The desired transparent area must have a smooth surface.

Following these rules will ensure that your 3D printed part comes out clear, but designers and engineers should keep a few additional factors in mind if they want to maximize transparency.

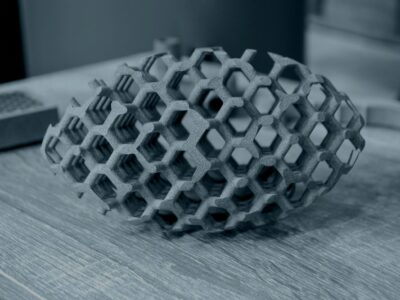

First, complex geometries — particularly curved designs — naturally refract more light and are less likely to come out clear. Also, thicker walls disperse more light than thin walls, and can therefore make a part look more opaque once it’s printed. To minimize light refraction and maximize transparency, design your 3D printed part with simple, clean lines and the thinnest walls possible.

Technologies for clear 3D-printed parts

Before you begin production you must decide what type of transparency you want, which is dependent upon the type of product you’re creating. For example, if you’re making a transparent vase, you only need transparency in the X- and Y-axes or transparency across the vase itself. If you’re making a flat window, on the other hand, you only need transparency on the Z-axis. Achieving complete transparency requires transparency across all axes.

Knowing which axes must be transparent will also help you choose which 3D printing process to use. The most common technologies used for printing clear or translucent parts are stereolithography (SLA), the Carbon Digital Light Synthesis Process™ (DLS process), fused deposition modeling (FDM), and PolyJet.

SLA

SLA is a 3D printing process that uses photopolymerization to create highly detailed parts from polymer resins. This process prints in very thin layers, making it ideal for transparent 3D printing and achieving complete optical transparency.

Also, SLA is well-known for producing smooth surface finishes. However, product teams should know that SLA 3D prints involve support structures that will need to be removed in post-production, which can affect the final appearance of your part.

The Carbon DLS™ Process

The Carbon DLS process is a resin-based polymer process that uses light and heat to create parts with isotropic properties, complex geometries, and excellent surface finishes. DLS offers a wide range of materials, including Whip Mix Surgical Guide and LOCTITE 3D IND405, both of which can be used to produce transparent parts.

Like SLA, the Carbon DLS process produces exceptional surface finishes. It also requires support structures that need to be removed in post production.

FDM

During the FDM process, a heated printing nozzle melts thermoplastic material and then extrudes it onto a set toolpath, revealing a finished product layer by layer. FDM gives product teams the freedom to create large translucent parts, but there are a few key limitations that they must consider. For instance, due to the nature of extrusion, very small gaps will form in between the layers of material, which reduces the amount of light able to pass through the clear 3D printed part.

Also, even though achieving transparency on the X-, Y-, and Z-axes of a part is possible with FDM, it can be very challenging. Finding the optimal settings for clear materials may take several attempts. You’ll need to optimize material extrusion temperature and flow rate, print bed temperature, printing speed, nozzle diameter, layer height thickness, and more to unlock the winning combination. This may not be an issue for seasoned engineers, but teams with less experience might consider choosing a simpler manufacturing process.

PolyJet

PolyJet is an advanced additive manufacturing technology that offers results comparable to injection molding, but with all of the benefits of additive manufacturing. During this process, a print head sprays a layer of photopolymer resin into a gel matrix and then cures the resin under an ultraviolet light. This produces incredibly smooth layers of material with equally smooth surface finishes. Like SLA, PolyJet is excellent for creating highly detailed parts.

Common 3D printing translucent materials

Here are five common translucent plastics and resin used to create clear 3D printed parts.

- LOCTITE 3D IND405: This new, clear resin from Carbon is tough, semi-rigid, and one of the most transparent 3D printing materials on the market today. Ideal for surgical guides, enclosures, and jigs and fixtures, this material is strong enough for a wide variety of use-cases and clear enough to give designers the aesthetic flexibility they need.

- Whip Mix Surgical Guide for Carbon Printers: As its name suggests, Whip Mix Surgical Guide is a good choice for transparent surgical guides because it’s non-cytotoxic, won’t cause chemical hypersensitivity over time, and complies with ISO 10993-1:2018 for use in dental or medical devices.

- Polyethylene terephthalate glycol (PETG): PETG is strong, formable, and impact-resistant 3D printing filament that offers excellent clarity. This material is also designed to reduce thermos-oxidative degradation and minimize yellowing due to ultraviolet light, which will help keep your 3D printed part crystal clear. Common applications include electric signage, machine guards, and food packaging.

- Acrylonitrile butadiene styrene (ABS): ABS is a common thermoplastic polymer found in home appliances, auto parts, pipe fittings, and even LEGO toys. Even though this material is translucent rather than transparent in its initial form, you can achieve transparency through post-processing and finishing.

- Polycarbonate (PC): Polycarbonate is a high-performance engineering thermoplastic that’s tough, strong, and easily thermoformed. In addition to offering excellent clarity, this clear 3D printing filament also has a glossy sheen to it.

Post-processing options and key considerations for translucent parts

No matter what 3D printing process or material you use, your part must go through post-processing to really shine. Manual sanding and polishing is among the best options for clear 3D printed parts with simple shapes and few details, but it’s very difficult to remove all layer lines through manual finishing alone. Also, manual sanding may leave micro-scratches on the surface. For best results, smooth the part’s surface with a range of incremental sandpaper grits and the polish it with an acrylic cleaner and a microfiber cloth — this is similar to the process used to make highly polished metal parts.

Spray coating is an easy way to improve clarity without reducing detail, making it ideal for parts with complex details. Simply applying a clear spray coating will conceal layer lines — but it may also cause yellowing. For a smooth, glass-like finish, prep the part by manually sanding the surface before applying the spray coating.

To achieve the clearest possible finish in post-processing, apply a resin coating. This approach only works on flat or nearly flat surfaces, but it’s the ideal choice for when you need fully transparent parts. Resin dipping can also be used to create a smoother surface for FDM- or PolyJet-printed parts. The viscous rein fills in any scratches in the part and forms a completely smooth surface.

Achieve crystal clear results with SyBridge

A lot of prep work goes into 3D printing translucent or transparent parts. You must determine what type of transparency your application requires, select the best-fit clear resin, choose a 3D printing process that will allow the most light to shine through, and finalize the part with the best finishing process. An experienced manufacturing partner can optimize the product development process from concept to delivery.

When it comes to selecting an experienced manufacturing partner, SyBridge is the clear choice. Our team of experienced engineers, designers, and technologists have access to the latest technologies and industry knowledge. Let us take the stress out of product development by helping you streamline your designs, prototype at speed, select affordable materials, manufacture efficiently, and fulfill your orders at a competitive price point and timeline. Take your clear 3D printed parts to the next level with SyBridge. Contact us today — let’s make something incredible.