Extend Tool Life.

Maximize Uptime.

Minimize Cost.

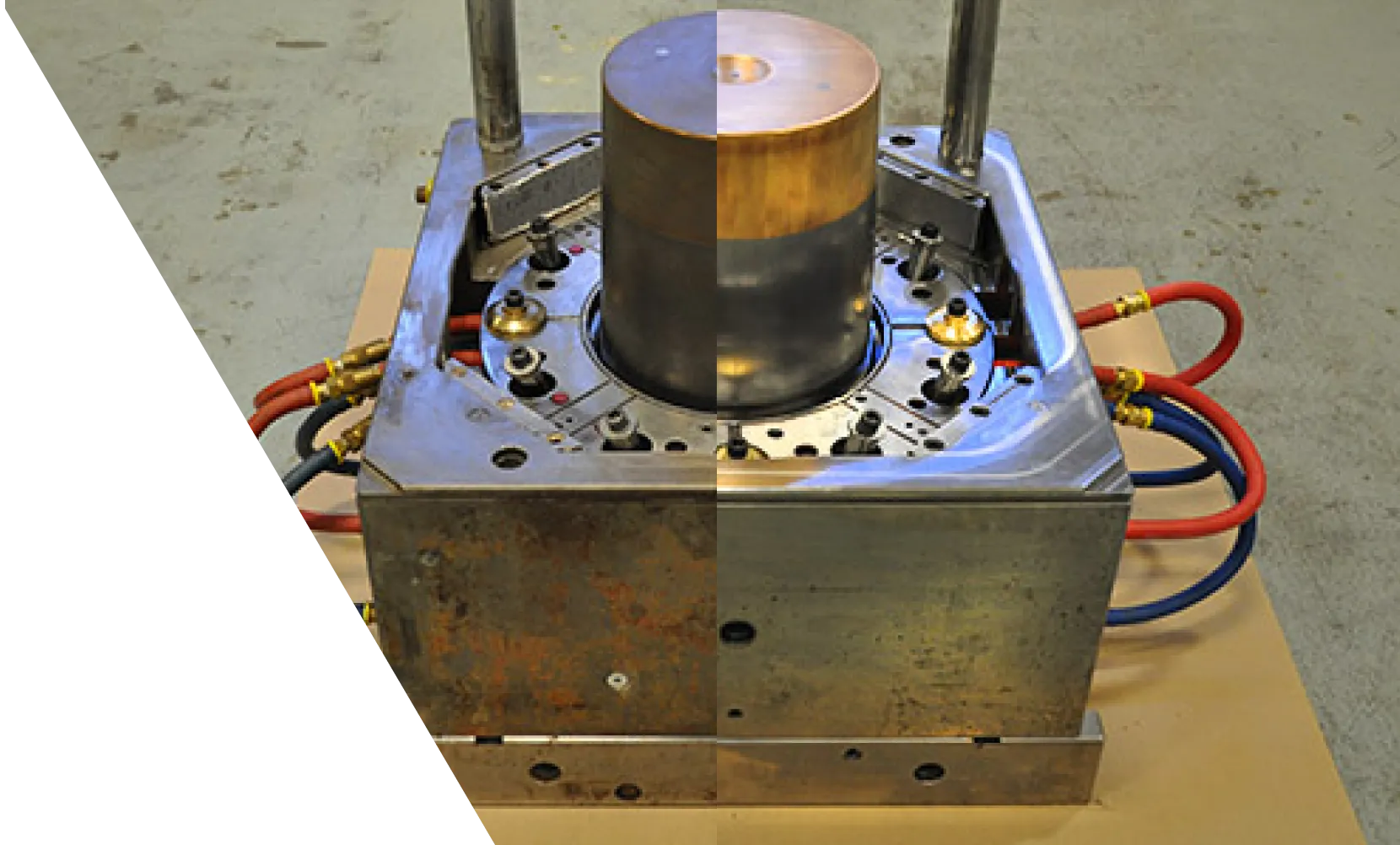

Comprehensive repair and maintenance services that keep your molds at peak performance

Reliable tooling is the foundation of reliable manufacturing. SyBridge keeps your molds performing at their best through replacement components, expert repairs, and complete refurbishment services. Whether it’s a routine inspection or an urgent repair, our expert technicians ensure your tooling stays production-ready—reducing downtime, protecting your investment, and extending the life of every mold in your fleet.

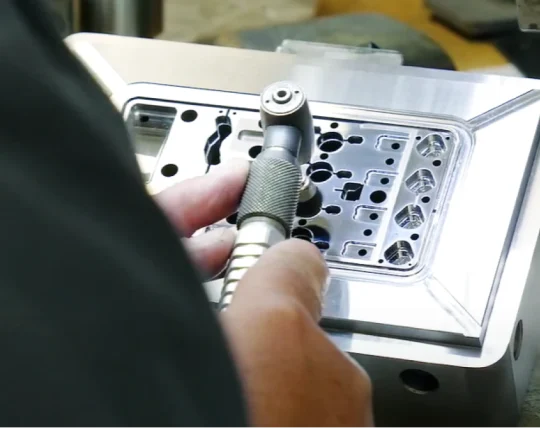

Preventive Maintenance that Protects Your Investment

Avoid costly downtime with preventive maintenance programs tailored to your specific tooling systems. Our experienced technicians can perform full mold teardowns, detailed inspections, and thorough cleaning and lubrication to identify potential issues before they cause disruption. We assess runners, gates, plates, hot runners, and water lines, restoring your mold to original print tolerances and ensuring consistent, high-quality part production.

We’re equipped to service and restore molds built by SyBridge as well as those from other manufacturers.

Comprehensive Services for Lasting Tool Health and Reliability

Ejector System Services

Landing Support

Requalification

Responsive Service—Minimizing Critical Downtime

Unexpected breakdowns can derail production schedules. When unplanned tooling issues arise, SyBridge is your partner for hands-on support. Whether you need on-site diagnostics, repairs at one of our advanced facilities, or a combination of both, SyBridge’s supportive approach ensures your molds are back in action with minimal disruption. From flash and alignment fixes to hot runner and ejector system repairs, we’re committed to keeping your operations running smoothly. Our regional network of service centers means help is always nearby. For troubleshooting, repairs, and collaborative problem-solving, our experienced technicians work side-by-side with your team to restore production quickly and efficiently.

Request Repair Support

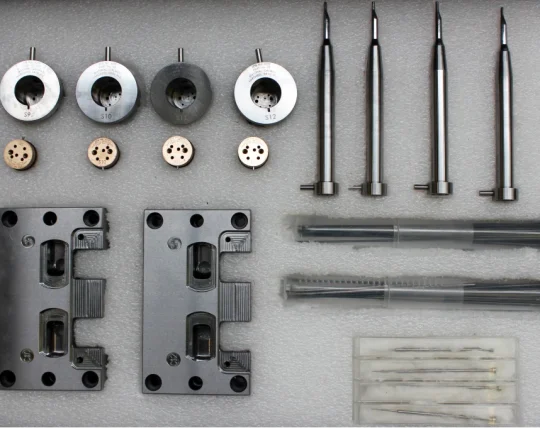

Spare Components to Keep Production Moving

Access to the right components can make the difference between hours and days of downtime. SyBridge produces spare and replacement mold components to your exact specifications, delivered quickly to keep your operations running.

From cavities, cores, and ejector pins to manifolds and wear items, our precision-manufactured components ensure compatibility and durability. We can also design and manufacture replacement parts for legacy or foreign-built molds, helping you maintain productivity without costly replacements.

Seamless Local and Global Landing Services

We manage all the logistics and setup of tools, whether you’re transferring your tooling locally or require global landing services.

- Uncrating

- Incoming Inspection

- Documentation of condition

- Manifold heat check

- Disassembly, cleaning, lubricating, and reassembly

- Clamp plate and hot runner inspection

- Functional testing and outgoing inspection

- Checklist with photo documentation

FAQs

SyBridge’s refurbishment services restore molds to like-new condition through laser welding, precision machining, and high-polish finishing (including A1). The process repairs cavities & cores, restores venting, and requalifies performance to improve reliability, cycle times, and part quality.

SyBridge manages complete tooling logistics and setup, including uncrating, inspection, cleaning, testing, and photo-documented checklists to ensure every mold is production-ready after transfer—whether locally or globally.

Yes, SyBridge is fully equipped to service and restore molds built by other manufacturers, including international manufacturers. This ensures you can maintain and repair all tooling in your fleet with a single, reliable partner.

Yes, SyBridge provides a full range of precision-manufactured spare and replacement mold components—from cavities and cores to ejector pins and manifolds—crafted to exacting specifications and delivered quickly. They can also design and manufacture parts for legacy or foreign-built molds.