Originally published on fastradius.com on July 8, 2021

Polymethyl methacrylate (PMMA) is a commonly used manufacturing plastic. Because of its high transparency, PMMA is also known as “acrylic glass” or “plexiglass.” The material characteristics of PMMA are noteworthy for a few reasons: it is a

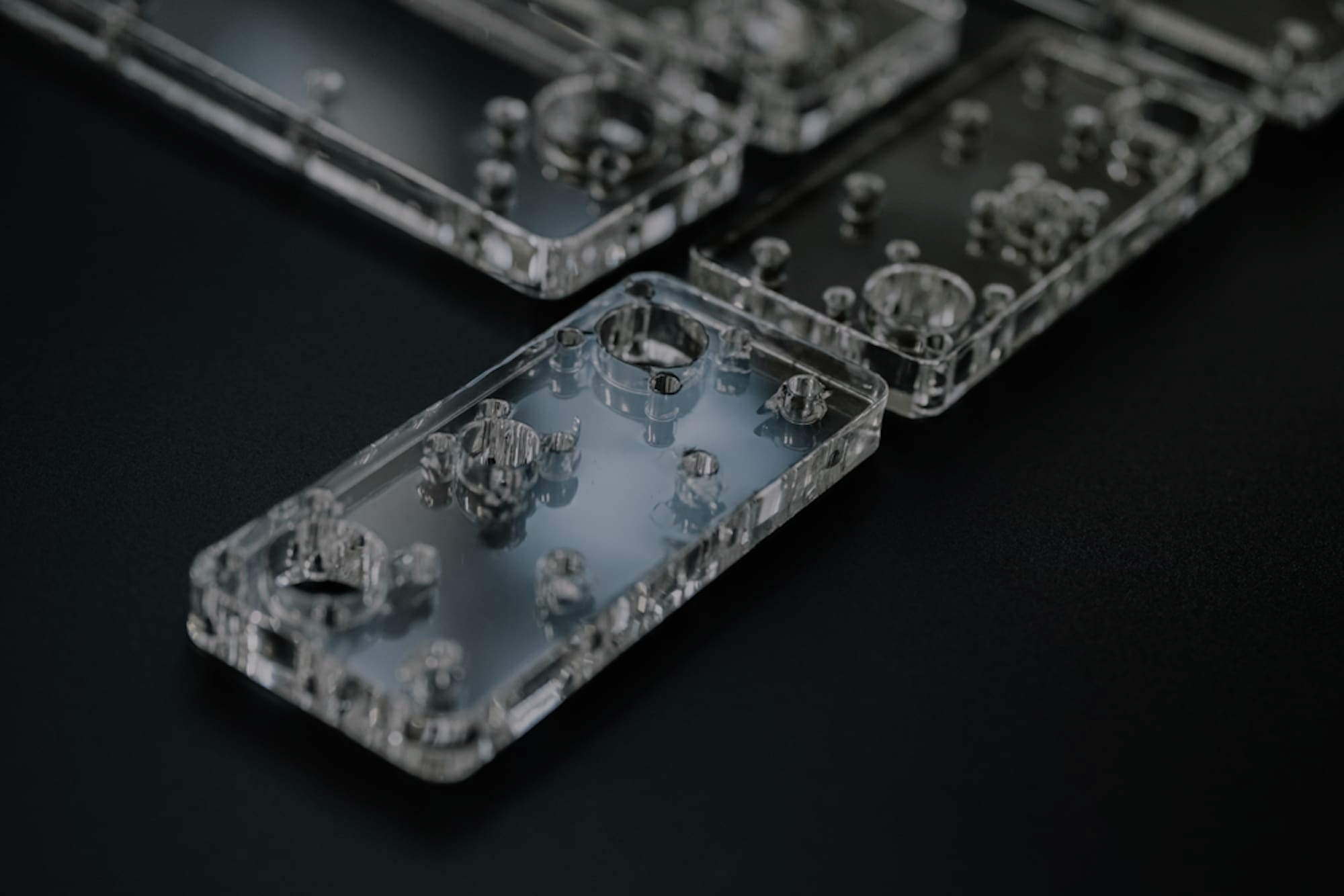

Polymethyl methacrylate (PMMA) is a commonly used manufacturing plastic. Because of its high transparency, PMMA is also known as “acrylic glass” or “plexiglass.” The material characteristics of PMMA are noteworthy for a few reasons: it is a highly translucent, glass-like material that offers high impact and environmental resistance, making it an excellent alternative for true glass in applications where shatter resistance is a desired trait. This includes aircraft and automotive windscreens, architectural applications, electronics, aquarium windows, and even medical implants.

Because of the wide range of potential applications and uses for PMMA, it’s important for product teams to fully understand the ins and outs of this versatile material in order to leverage its benefits most fully. Here’s what you need to know.

PMMA, or poly(methyl methacrylate) is a clear, colorless polymer with the molecular formula C5H8O2.

PMMA is produced through polymerization, which involves placing the methyl methacrylate monomers into a mold with a catalyzing agent. This allows PMMA to be formed into a wide variety of shapes, ranging from large sheets and blocks to small pellets and granules.

PMMA is compatible with all thermoplastic manufacturing methods (including injection molding, compression molding, and others), and can be subsequently machined, sized with saw or laser cutting, or polished.

PMMA has a refractive index of 1.49 and can allow up to 92% of light to pass through, which is more than many other thermoplastics and even some grades of glass. PMMA is also lightweight — typical density for the material is 1.17-1.20 g/cm3, or half that of glass — and much more resistant to impact and shatter than glass. PMMA can be thermoformed without losing any of the material’s optical clarity. At the same time, PMMA can also be colored or dyed to match any shade, extending its versatility to applications beyond glass replacement.

For instance, PMMA also provides good resistance to UV light and environmental wear, which can be further improved with stabilizers and additives. Not only that, PMMA is tough and durable, offering better scratch resistance than polycarbonate (PC) and other transparent polymers, and demonstrates low moisture absorption, allowing it to be used in the creation of parts where dimensional stability is critical. PMMA is therefore ideal for outdoor applications where the part or apparatus is intended to withstand exposure to the elements.

Despite being created from methyl methacrylate, which is a known irritant and suspected carcinogen, PMMA is extremely biocompatible, leading to the material finding use in various medical applications, including contact lenses, dentures, bone replacements, and even cosmetic surgery, where it is used to help reduce wrinkles or scars. In fact, PMMA is sometimes known as “bone cement” in medical circles because of how frequently it is used to cushion implants against the skeleton. PMMA is also simple to polymerize within a hospital environment, making it especially useful in medical manufacturing.

While PMMA can be food-grade, it is not safe to use in microwaves or dishwashers, as the material is only dimensionally stable to temperatures of 149°F (65°C). Typically, glass is recommended over PMMA for applications involving food.

As mentioned, PMMA is similar to PC and other translucent plastics, but this material stands out from the pack in a few key ways.

One of the most noteworthy advantages of PMMA is its scratch resistance. It is well suited to optical lenses and devices, as the material is less likely to splinter, shatter, or cause harm to someone’s skin or eyes if the lens or device happens to break. Parts made from PC, in contrast, are much more prone to scratching and denting the longer they are used.

PMMA is more brittle than PC, meaning that it remains stiff and cracks when stressed or impacted. While PMMA does provide some shatter resistance, PC is able to provide much greater impact strength, and in some applications, these two qualities can be used in tandem. Display windows, for instance, may be crafted from an outer layer of scratch- and shatter-resistant PMMA and an inner layer of a wind-resistant and highly impact-resistant material like PC.

PMMA also offers a cost-effective alternative to PC when a given application would benefit from greater tensile and flexural strength, light transmissibility, surface polishability, and UV resistance. PC, on the other hand, is a more expensive material to manufacture with and is better suited for applications that require high impact strength and chemical and heat resistance.

PMMA is a highly versatile thermoplastic resin noted for being a strong, lightweight, and cost-effective alternative for many applications where glass might otherwise be used. However, this weather-resistant material also happens to be biocompatible, leading to its use in a wide range of medical devices as well. There are a number of reasons you might want to consider using PMMA for your product, but ultimately, it’s up to you to determine which materials are best suited for your parts– ideally with the help of a trusted manufacturing partner.

SyBridge is leading the charge in rethinking modern manufacturing capabilities. Our cutting-edge on-demand manufacturing platform makes it easy for customers to engage with us during every step of the production timeline, from product design to fulfillment. Our team of dedicated designers and engineers specializes in creating high-quality parts from a wide breadth of materials. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…