Originally published on fastradius.com on September 11, 2020

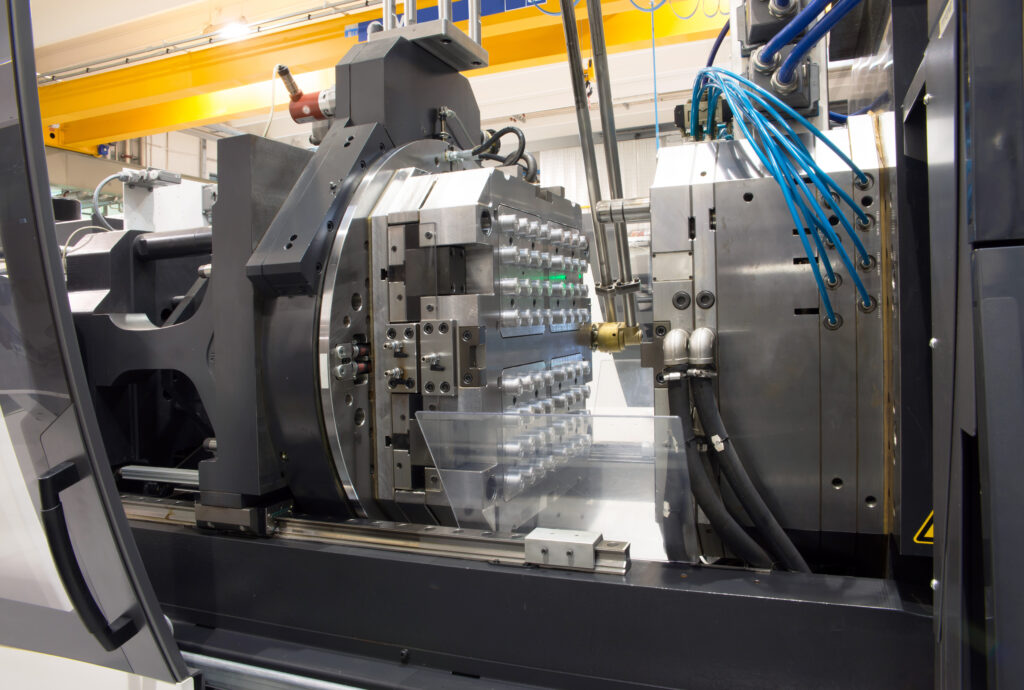

One of the most widely-used methods in plastic parts manufacturing today, injection molding can facilitate large, cost-effective production runs of identical parts. In fact, in most cases, injection molding is the most cost-effective method for producing plastic parts in medium to high volumes. For this reason, it’s frequently preferred over other methods of manufacturing, including CNC machining, urethane casting, and die casting.

Injection molding may be facilitated by means of a single- or multi-cavity mold. While the processes of both single- and multi-cavity injection molding require the same basic set of operations in the same chronology, the two are generally used to meet different demand or timeline requirements and are therefore rarely interchangeable. Choosing whether to use a single- or multi-cavity injection mold is vital to the success of a project. Here are common use cases, advantages, and disadvantages of each.

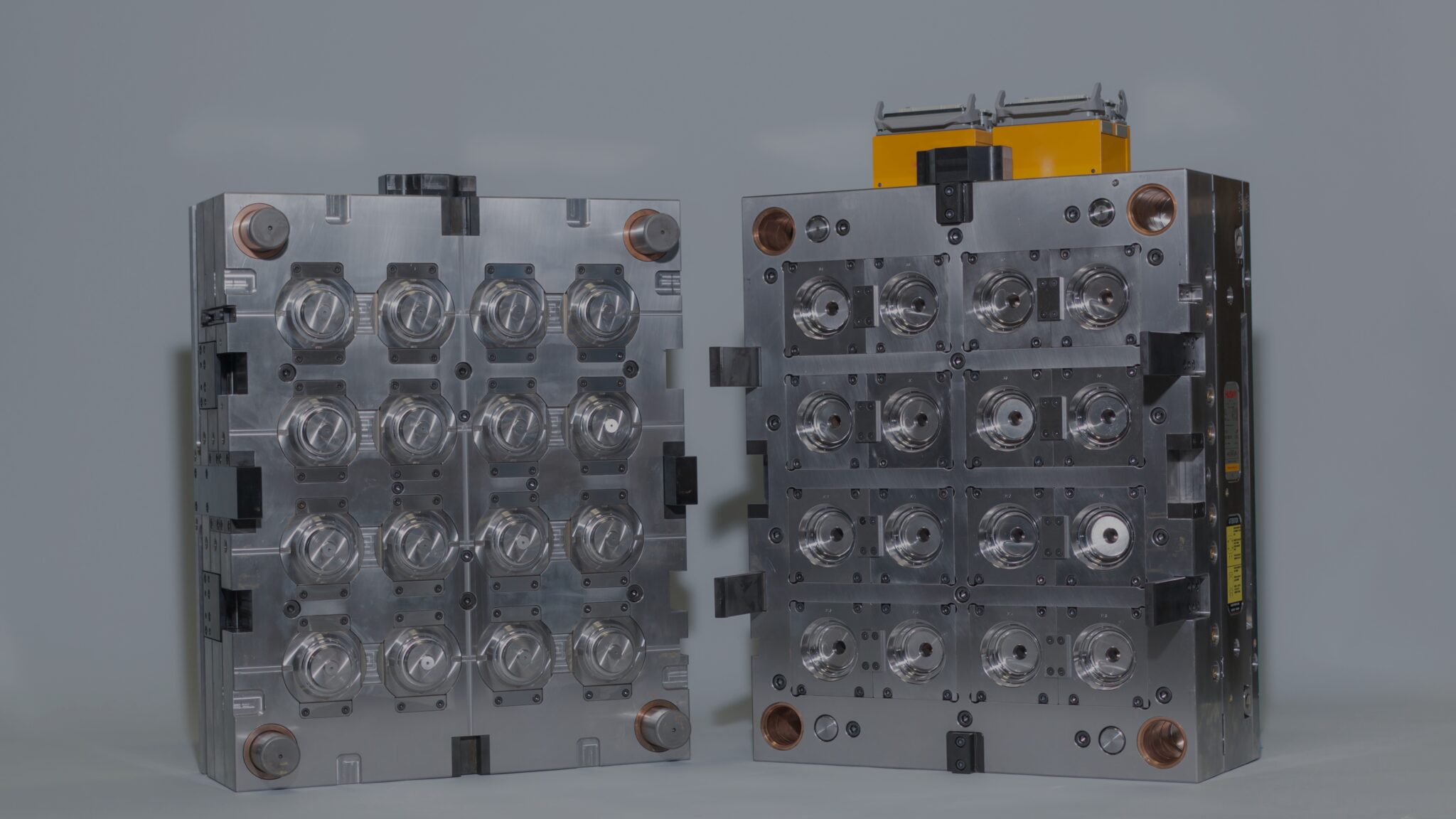

Injection molding begins with creating the mold itself. The mold, which will later be filled with melted plastic to create the desired part, represents the most complex component of the injection molding process. Fortunately, it only needs to be created once.

Once the mold has been made, injection molding becomes an easily-replicated six-step process. The first step is clamping, or pushing the mold’s two clamshell-like halves together. Next is injection, in which plastic is melted down and inserted into the mold. Dwelling and cooling, which allow the plastic to fill the mold and solidify, follow. Finally, the mold opens, and ejector pins remove the part.

Choosing whether a single- or multi-cavity mold is best-suited for a given project tends to be more complex than one might expect.

In general, the choice between a single- or multi-cavity mold comes down to timeframe and demand. When many identical parts are needed within a set time frame, a multi-cavity mold is often the better choice. Multi-cavity molds enable manufacturers to create more parts, faster — a clear advantage of using multiple cavities at once.

However, multi-cavity molds aren’t always the best fit for a given project. A multi-cavity mold requires a far more substantial upfront investment than a single-cavity mold. It is more cost-intensive to create multi-cavity molds because they require more material, labor, and energy resources than a single-cavity mold. While the investment in a multi-cavity injection mold can certainly pay off if producing parts at high volumes, at lower volumes, it may make more sense to opt for a single-cavity mold.

Multi-cavity molds require more substantial lead time, as they take longer to create than single-cavity molds. In addition, maintenance costs and risk is higher with multi-cavity molds; if one cavity breaks or has a flaw, the entire mold can become unusable, which can significantly impact time-to-market.

It’s always wise to know your market and have a firm understanding of the demand for your product so you can design and manufacture to minimize your costs. This is especially true when it comes to injection molding. Given the time and substantial cost required to create a mold, it’s vital that product teams do their due diligence and select the mold type that best suits the product and the demand in the marketplace.

Fortunately, an experienced design partner like SyBridge can help make those decisions easier. We’re experts in the process of creating the perfect mold — and in Design for Manufacturing (DFM) principles. If you’re ready to get started, contact us today to hear more about our injection molding services.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…