Originally published on fastradius.com on June 12, 2020

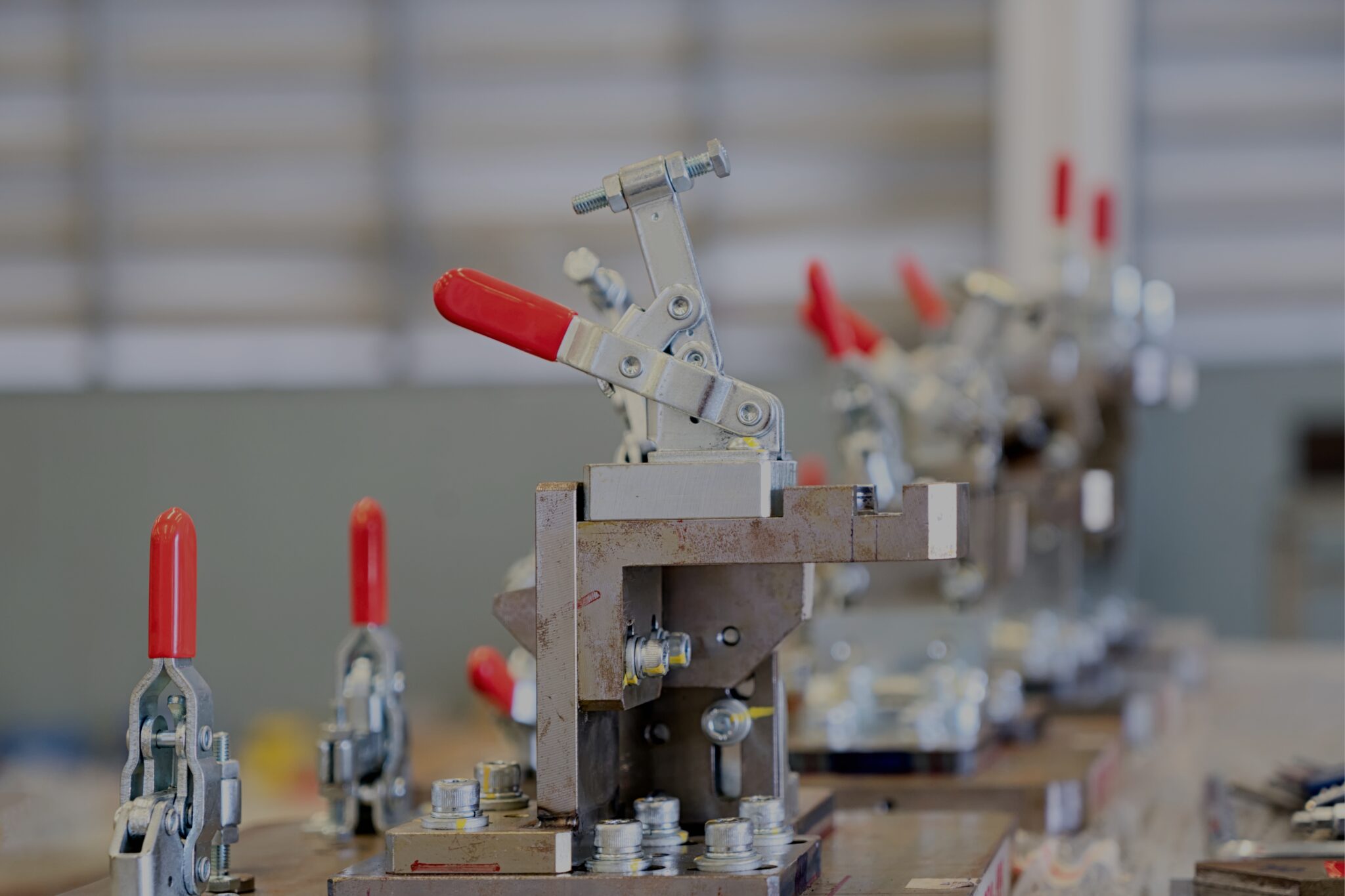

Jigs are tools that hold a manufacturing tool in place as it performs a repetitive task like drilling or tapping holes. Fixtures, on the other hand, don’t guide a manufacturing tool but hold a workpiece steady in a fixed position, orientation, or location. A standard vise is a common household example of a fixture.

Differences aside, both jigs and fixtures are tools that make a big difference. They increase productivity, improve the repeatability of parts, make part assembly and disassembly easier, and even help create a safe working environment. Nearly all automated industrial manufacturing processes rely on jigs and fixtures to consistently build parts that function properly. Engineers can make sure their jigs and fixtures are strong and well-designed by keeping these key considerations in mind.

The key to manufacturing jigs and fixtures starts with understanding how degrees of freedom work. Any object in space has six degrees of freedom — up/down, left/right, forward/backward, and the ability to rotate about 3 axes (X,Y, and Z). A properly designed fixture needs to restrict these freedoms as much as possible to keep the part locked in position, but not so much that the part is overconstrained.

Overconstraint happens when redundant forces try to do the same job and end up working counterproductively. A four-legged chair is an excellent example of this — the fourth leg is mechanically unnecessary and will cause rocking if the chair is on an uneven surface. At best, overconstrained forces will have no effect on the fixtures but in the worst cases, it results in poor part quality and increased risk to the operator.

It’s essential for engineers to be precise when it comes to freedoms. A less constrained fixture design is best for parts like castings that have a little more variation, while a more constrained fixture design is best for CNC machined or injection-molded parts with more precise surfaces.

A successful jig and fixture design takes into account how the tool will operate as well as how it will feel to operate the tool. Each application will differ, but engineers should always incorporate human-centric design into their plans. Start with these fix jig and fixture design calculations:

Jigs and fixtures can be manufactured using CNC machining and 3D printing, but in general, 3D printing offers a number of advantages. In this case, additive manufacturing is cheaper and faster than CNC machining by a wide margin. Also, only 3D printing offers engineers the flexibility to frequently re-optimize design.

Jigs and fixtures can be built using metal or plastic materials, but plastic tends to be more affordable and can often meet all performance requirements. Industrial fused-deposition modeling (FDM), HP Multi Jet Fusion, and Carbon Digital Light Synthesis (DLS) give excellent results, but stereolithography (SLA) and selective laser sintering (SLS) can be good options, too. For rapid injection molding, engineering-grade thermoplastics can easily produce isotropic parts in high volumes.

For high-performance, durable jigs and fixtures, keep these manufacturing best practices in mind:

After the jig or fixture has been manufactured, it must be validated for form and function. Engineers should compare the completed tool against the original CAD model to make sure it’s dimensionally sound. A well-designed fixture will support the part and hold it in place, once clamping is applied, without any tilting, bending, or shifting.

Jigs and fixtures are essential components of any manufacturing project. They boost productivity, accelerate production timelines, and enable the production of better parts. As such, it’s critical that engineers do whatever possible to make their jigs and fixtures as functional as possible. An experienced manufacturing partner can help.

The SyBridge team is committed to helping product teams bring their ideas to life. Our design and engineering experts are happy to help you architect a breakthrough application or ensure that your jigs and fixtures are based on a flawless, functional design. We work with customers from concept to delivery, ensuring the entire product lifecycle is optimized for speed and cost-efficiency. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…