Originally published on fastradius.com on April 27, 2022

If you need to produce plastic parts, there’s a good chance you’ll end up using injection molding. Since this precise manufacturing process is a cost-effective way to produce medium and high volumes of identical plastic parts, it’s often a better choice than production methods like CNC machining or urethane casting.

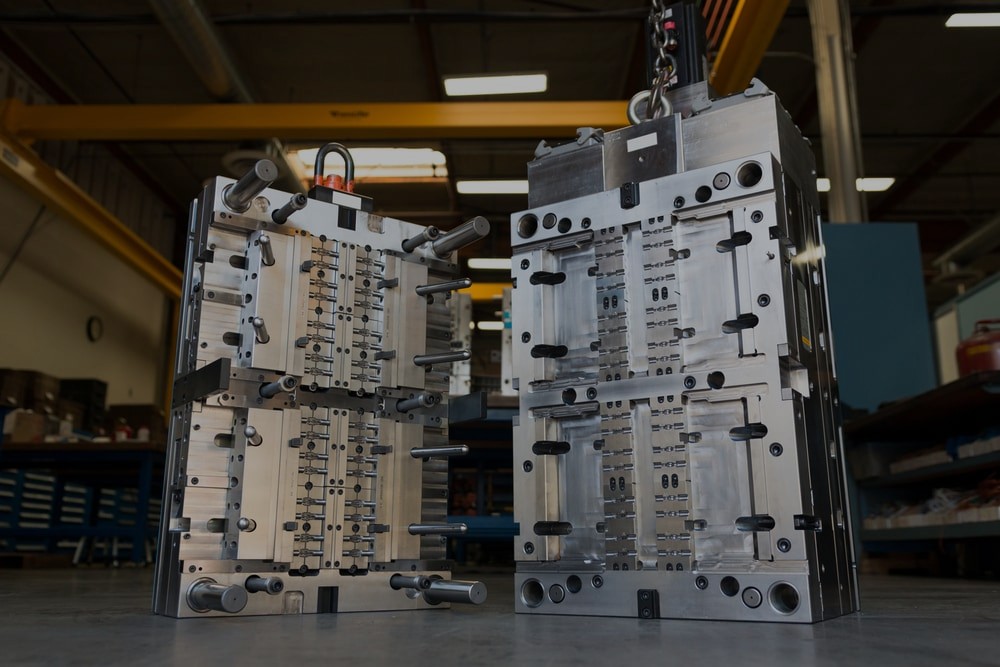

However, creating a mold is a long and expensive process, so you want to make sure you have the right mold from the start. In some situations, single-cavity molds, or molds that produce one product per cycle, are the way to go. In others, you might be better off with a multi-cavity mold that can produce multiple products per cycle.

In this article, we’ll go over the basics of multi-cavity injection molding — including its pros, cons, and use cases — so you can decide whether or not using a multi-cavity mold is best for your project’s requirements.

Multi-cavity injection molding is a form of injection molding that involves molding two or more identical parts per cycle. Multi-cavity molds can contain anywhere between two and 164 cavities, and they typically increase in increments (2, 4, 8, 16, 24, 32, etc.). Stack molds — molds containing a mirror image of the tooling making the parts — are classified as multi-cavity molds because they ultimately produce identical parts. However, family molds — molds that produce multiple parts that are similar in size or appearance but not identical — cannot be classified as multi-cavity molds.

Companies use multi-cavity injection molds for many different products in various industries including consumer goods, medical, and automotive.

Product teams often start with a single-cavity mold to validate their design before shifting to a multi-cavity injection mold. Single-cavity molds are less expensive and quicker to produce. However, in some cases, it makes more sense to use a multi-cavity mold from the start. Manufacturing the same large volume of parts with a single-cavity mold rather than a multi-cavity mold means more cycles, more machine time, and higher costs. Multi-cavity molds will enable you to create more parts in less time and at a lower cost per part.

At SyBridge Technologies, we generally recommend having two cavities for products with over 10,000 estimated annual units (EAUs), four cavities for products with EAUs greater than 50,000, and eight cavities for products with over 100,000 EAUs.

Using a mold with multiple cavities as opposed to one offers several advantages. Multi-cavity injection molds use cycle times more efficiently, so you can produce more parts per hour. This increase in production efficiency makes it possible to fulfill high consumer demand faster. Despite the high initial costs associated with multi-cavity molds, they can also help you lower your cost per part and save money on high-volume production runs.

Different types of runner technologies are used when designing single-cavity and even multi-cavity molds. Cold runners are typically used in prototype tooling to reduce initial investment. However, this increases material waste and there is a cost involved in re-grinding the excess material back into the process or disposing of it. Hot-runner technologies are typically used in proven-out designs to reduce material waste per cycle. Most multi-cavity molds use such technologies.

However, multi-cavity injection molding also has its drawbacks, starting with the cost of creating the mold itself. Multi-cavity molds require more upfront investments than single-cavity molds because they take more material, energy, time, and labor to produce. If you have a limited budget or are planning to manufacture parts at lower volumes, using a single-cavity mold might be more practical.

Multi-cavity molds also take longer to create than their single-cavity counterparts. If you need to get products on the market quickly, a single-cavity mold or another manufacturing method with a shorter lead time might be best. Plus, multi-cavity molds have higher maintenance costs and risks, which can increase your time to market. After all, if one cavity develops a flaw or breaks, the entire mold can become less efficient or even unusable.

It’s also worth noting that multi-cavity injection molding requires a deep understanding of balance of fill to achieve repeatable parts, so most manufacturers who only work with single-cavity molds will face a learning curve when switching to multi-cavity molds. They’ll need to ensure that all components within a multi-cavity injection mold are extremely precise and have comparably sized gating to ensure the best results.

When deciding whether to use a single-cavity vs. multi-cavity mold, you need to think about your desired production run volume, budget, and lead time. Since multi-cavity molds are more expensive and take longer to create, they aren’t ideal for small production runs and limited budgets. However, they can produce more parts in the same period of time than single-cavity molds, so they’re best for medium or large production runs.

Other design modifications might include:

Everything from a part’s size and complexity to the mold’s material to the number of cavities can affect the price of a multi-cavity injection mold. There’s no blanket multi-cavity injection molding price guide, but generally, the more cavities you have, the more resources you’ll need and the more your product will cost to produce. You’ll also face higher maintenance costs, as your manufacturing partner will need to maintain several cavities rather than one.

However, when it comes to high-volume production runs, multi-cavity molds offer a large return on investment. You’ll be able to save money on machining, labor, and setup time, achieve a cheaper cost per part, and maximize your profits, as higher cavitation will enable you to create more parts in less time. While multi-cavity molds require a significant amount of money upfront, you’ll save time and money in the long run.

You can further reduce costs by using robotics or automation and having a clear understanding of how many parts you’ll need to produce. For example, if you know consumer demand will increase, it makes sense to start with higher cavitation, rather than create a single-cavity mold and then a multi-cavity mold.

Multi-cavity molds can save you time and money, but they aren’t the best choice for every project. Since creating an injection mold requires investing a substantial amount of time and money, you need to know your expected consumer demand when deciding whether to create a single-cavity or multi-cavity mold. Otherwise, you may find yourself spending money creating a single-cavity mold only to quickly switch to a multi-cavity mold, or investing in an expensive multi-cavity mold when a single-cavity mold would be sufficient to meet consumer demand.

If you know your EAU, an experienced design and manufacturing partner like SyBridge can help you determine which type of mold is best suited for your project. We’re ready to bring your ideas to life, and we can also offer advice regarding mold material, part material, mold design, and more, so you can create high-quality parts as cost-effectively as possible. We can even help you avoid the biggest injection molding mistakes. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…