Originally published on fastradius.com on October 8, 2020

Injection molding is a production method that allows manufacturing companies to quickly create large quantities of identical products. The process involves using a highly pressurized nozzle to fill a variety of molds with molten material.

Typical straight-pull injection molds have two halves — the core and cavity — that separate, allowing the part to be removed efficiently. In order for a straight pull mold to be designed, a part must be able to be ejected along the line of draw without any obstructions. While this might sound simple, this requirement actually places some significant limitations on engineers and designers.

Design features that obstruct the ability of a part to release from its mold along the line of draw are called undercuts — but they aren’t necessarily something that must be avoided. In fact, useful design features like snaps and latches, side ports and holes, vertical threads, and barb fittings are all examples of undercuts, many of which are commonly used in medical equipment and plastic consumer products. Before a part with undercut features can be released, the portion of the mold that creates the undercut must first be removed.

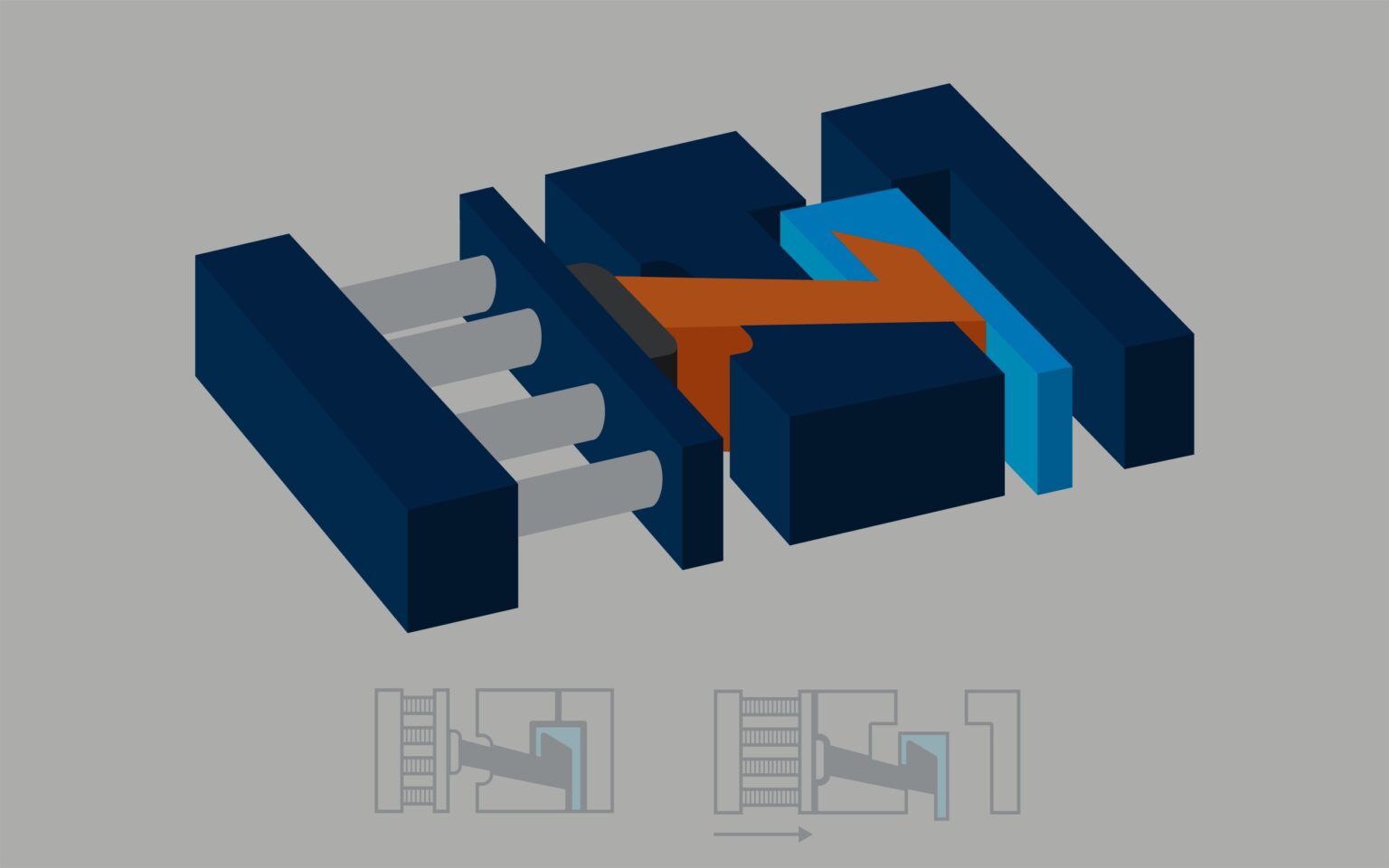

Actions are special features designed into a mold that allow molding of undercut features, but retract to also allow straight ejection of the part. While actions increase the costs and lead times associated with tooling, the additional expense often pays for itself, by allowing manufacturers to produce viable parts with undercut geometries.

Here are a few of the most common actions.

Cams are simple devices that pull the undercut mold surfaces away from the part, allowing the mold to open. The most common type of cam device uses an angled pin to control the movement of the action, which opens and closes at the same speed as the rest of the mold. Cams allow for far greater geometric complexity in part design without requiring any additional external setup or adjustments from operators during production.

Furthermore, the cam pin itself needs to be monitored over the production lifecycle, as steel is a compressible and flexible metal, which can lead to inconsistent part quality if additional load compresses the pin.

Lifters help to release internal undercuts or internal faces with no draft. After the part has cooled, the lifter pushes up at an angle, which removes the undercut section from the mold, and retracts from the undercut during ejection. However, rather than using an angled pin to control the action’s movement, lifters are driven by the action of the injection molding press pushing against the ejector plates.

A basic action lifter will withdraw simultaneously with ejection — only perpendicular to the line of draw. While the lifter moves at an angle relative to the core mold, it moves sideways relative to the part, which allows the undercut surfaces to be ejected at the same rate that the lifter withdraws. Internal features like draft, ribs, and bosses need to be modified to accommodate the lifter’s range of motion.

In contrast to lifters, action sliders release external undercuts. Similar to cam devices, sliders use angled pins attached to the core mold to pull the slide away from the finished part, allowing it to be removed easily. They can also be solenoid- or hydraulically-driven.

Parts with threaded features — such as screws and other fasteners — are complicated to remove from injection molds. External threads can be easily incorporated into mold design, so long as the threads are perpendicular to the line of draw. Internal threads and non-perpendicular external threads require an external unscrewing mechanism. The action is inserted into the mold before injection, then unscrewed from the part after the material has set.

Collapsible core actions are useful for releasing circular undercuts. Parts are molded directly around the action, the core of which collapses once the material is set. This allows the action — and the part — to be removed easily from the mold. Collapsible core actions can also be used to create threaded features.

Undercuts allow engineers to create useful, geometrically complex part designs, but at the price of making parts difficult to remove from their molds. The solution for manufacturers is incorporating actions into tools in production tooling, which allow the undercut features to be easily released from the mold without damaging the part.

The help of a trusted on-demand, digital manufacturing partner like SyBridge Technologies helps to simplify the entire product lifecycle — from prototyping and tooling through post-production and fulfillment. Our dedicated team of designers, engineers, and product managers work tirelessly on each job to ensure that the parts we create are made from high-quality materials and delivered on time. In fact, our processes are so efficient, that in many cases, we’re able to pass those time- and cost-savings onto our customers. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…