Originally published on fastradius.com on January 4, 2021

Additive manufacturing, commonly referred to as 3D printing, is a manufacturing method that lays down successive layers of material driven by the contours of a 3D model to create physical objects. The field of additive manufacturing has witnessed steady growth in both technological development and adoption over the years. Today, engineers have a wide variety of 3D printing processes to choose from. The process that started it all, however, was vat photopolymerization.

Vat photopolymerization was the first additive manufacturing process to be successfully commercialized, and it remains a popular technique some forty years after its market debut. Let’s take a deep dive into the original additive manufacturing process.

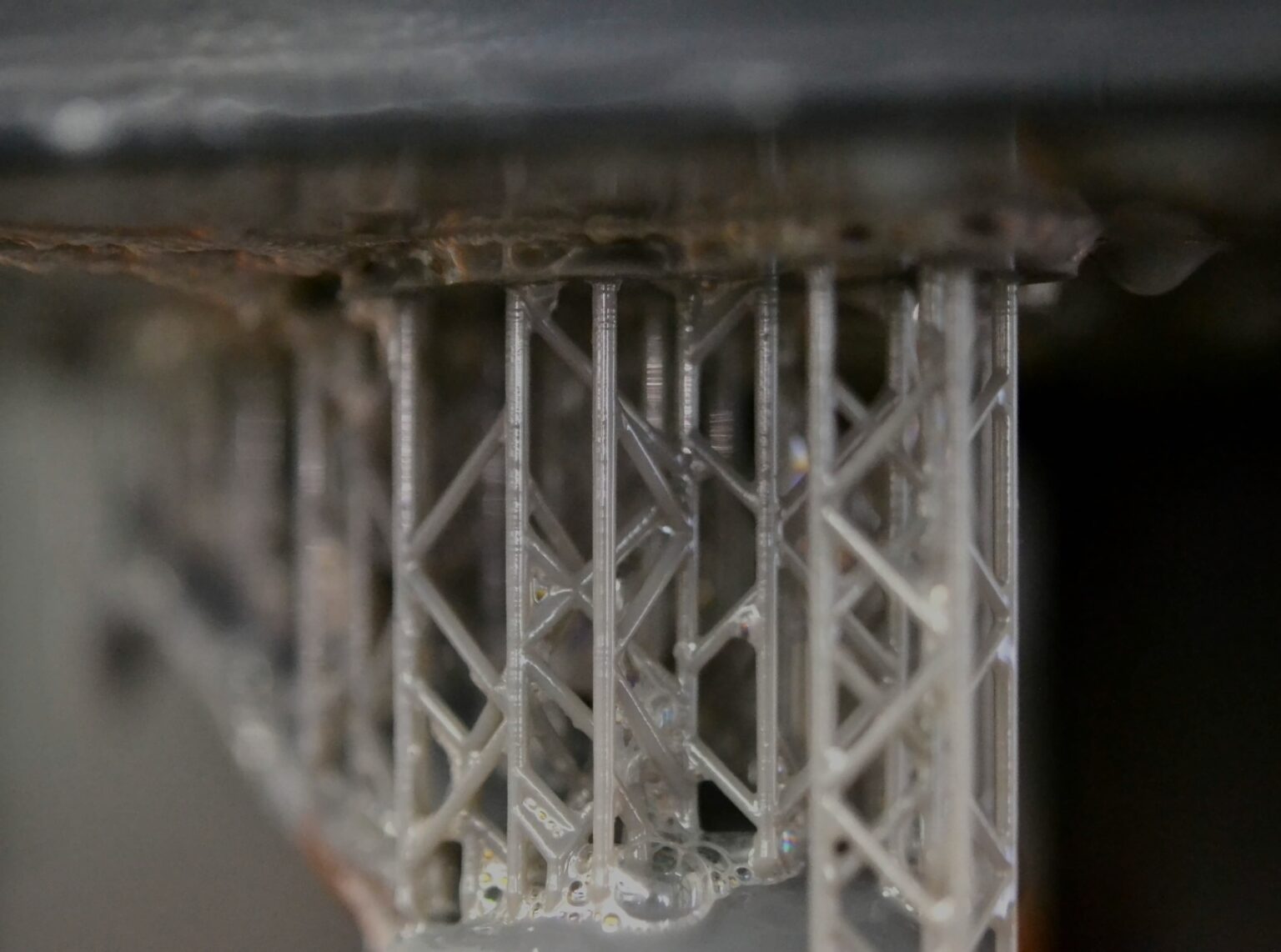

Vat photopolymerization creates parts with excellent surface finishes by curing a liquid photopolymer resin one layer at a time using light. First, the build platform is lowered into the vat of resin. Then, UV light, typically from a laser or projector, causes a reaction within the resin. The photopolymer’s molecules bond together to form a solid, and the build platform moves away from the light source to allow additional layers to be built on top of the previous ones. After the part is fully formed, the resin is drained and the part is removed.

The most common vat photopolymerization 3D printing technologies include:

During SLA, a laser of ultraviolet light located inside the vat photopolymerization machine is focused on the vat of resin to build a part layer by layer.

DLP produces parts in the same way as SLA, with one key difference. Instead of using a laser, this process uses a digital light projector screen that flashes a single image of each layer of the part into the resin all at once. As a result, the printing process is accelerated.

DLS is similar to DLP, except that the movement of the build platform is continuous as opposed to discrete, enabled by a “dead zone” that prevents the part from curing to the projection window. DLS is even faster than DLP because the vat photopolymerization machine does not need to stop and separate the part from the build plate after completing each layer.

Vat photopolymerization processes are ideal for creating highly accurate parts with fine details and smooth surface finishes. Common applications are seen across the medical and dental industries, some of the most common being surgical learning tools, facial prosthetics, and hearing aids. Manufacturers can also use vat photopolymerization to make molds for low-volume injection molding.

Vat photopolymerization materials vary by process. For example, SLA is compatible with a wide range of photopolymer resins — standard, tough, flexible, transparent, and castable. DLP, on the other hand, is only compatible with standard and castable resins. Carbon DLS also has its own materials. Resins are not universal; each type of resin endows a part with a respective set of physical and chemical properties. Engineers and product teams should always define their project requirements carefully and evaluate potential materials against these requirements.

Vat photopolymerization has remained popular among manufacturers over the years because it is ideal for manufacturing highly detailed parts and is often faster than other manufacturing processes in terms of pure volume. Furthermore, vat photopolymerization machines can have large build volumes. Advances in quality, speed, and printable part size have accelerated the commercial viability of these technologies.

Historically, the primary limitation of SLA and DLP processes came from the physical restrictions of various vat photopolymerization-compatible materials. With the exception of select tough and rigid resins, UV curable resins weren’t known for their strength, durability, or stability. These resins can warp and deform over time, change color, and typically have to be post-cured for a long time to draw sufficient strength from them. The Carbon DLS process addresses these shortcomings with materials that are far more stable. DLS makes much stronger, more durable parts with isotropic properties.

Vat photopolymerization is a tried-and-true additive manufacturing process capable of producing intricate and detailed parts, exceptional surface finishes, and large volumes. It’s fast, versatile, and affords product teams a fair amount of design flexibility.

Product teams today have a wide range of additive methods to choose from, even beyond vat photopolymerization. A trusted, on-demand manufacturing partner like SyBridge can make choosing the right additive manufacturing method much easier.

SyBridge is a one-stop-shop for production-grade additive manufacturing, offering vat photopolymerization services alongside a full suite of traditional manufacturing offerings. Our factories are home to the latest additive capabilities, which are augmented with our agile, on-demand production model. Employing a proprietary digital platform, we streamline and optimize the manufacturing process from concept to delivery — so our customers can focus on what they do best: innovating and bringing products to market at speed. Contact us today — let’s make the impossible possible.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…