Originally published on fastradius.com on May 12, 2021

If you look closely at the innovations coming out of the top industries today — automotive, medical, aerospace — odds are you’ll find some form of robotics technology. Recent advancements in computing and sensory technology have inspired explosive growth in advanced robotics manufacturing, and the applications are wide-ranging. Within the last few years, we’ve seen surgical robots perform intricate procedures, robot dogs assist military and law enforcement officials, and much more.

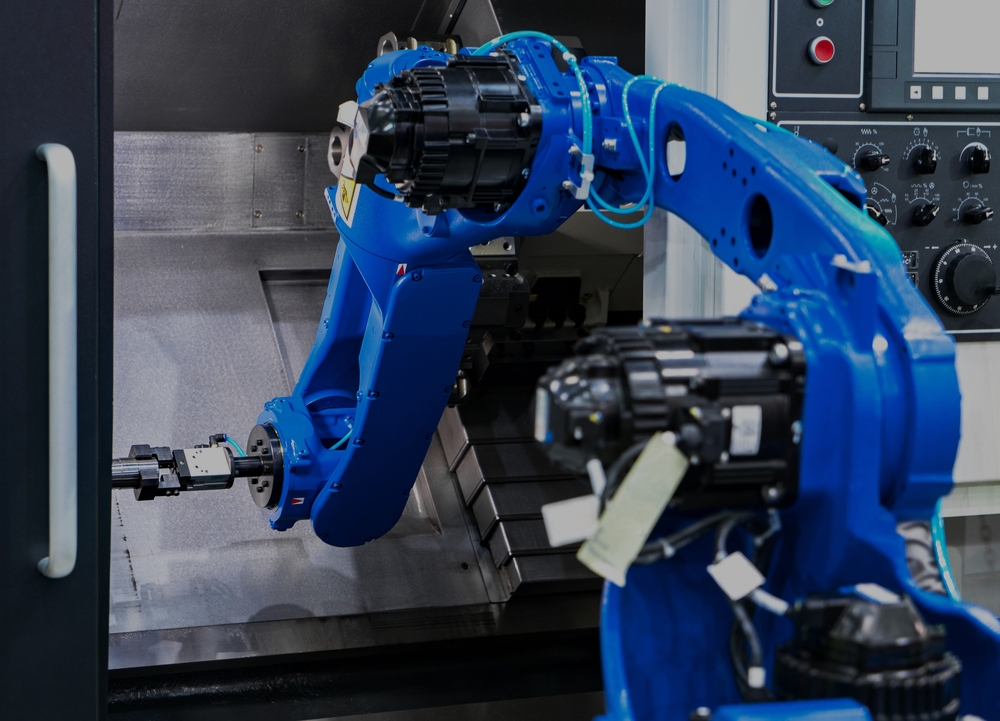

Even though the robotics industry changes rapidly and capitalizes on the most cutting-edge technologies available, the processes used for manufacturing robotics parts also include tried-and-true traditional processes like CNC machining and urethane casting.

Urethane casting is typically associated with prototyping and low-volume production runs of consumer goods like ergonomic grips and skateboard wheels, but this process plays a surprisingly important role in advanced robotics manufacturing. Here’s what you need to know:

Urethane casting is a versatile manufacturing process that allows you to create high-quality flexible and rigid plastic parts without the expenses associated with injection molding or the costs of laborious hard tooling.

During the urethane casting process, a master pattern — created using 3D printing or CNC machining — is placed in a mold box and then filled with liquid silicone. Once the silicone has cured overnight, the silicone block is cut into two pieces, revealing the mold that will be used to create additional copies of the part. Each piece of silicone is reassembled, filled with urethane casting resin, and placed in a heated vacuum chamber to cure. Once cured, you’ll have a 1:1 scale replica of your master pattern that requires little if any post-processing.

Ideal for low- to medium-volume production runs, urethane casting is easy to use and boasts faster turnaround times than injection molding. However, the cost per part can be high, and strict thickness requirements can limit design flexibility. These pain points notwithstanding, product teams can still manufacture many different kinds of high-quality parts with urethane casting. Common applications include logos, molded bearings, mechanical joints with overlapping features, as well as robot parts.

In general, the mechanical and chemical properties of urethane casting resins render them excellent materials for advanced robotics manufacturing. Urethane casting materials are known for their wear, abrasion, corrosion, and chemical resistance. Plus, urethane casting parts are excellent for minimizing unnecessary vibration.

These characteristics are advantageous to industrial robot manufacturers, designers, and engineers who need parts for robots that will be operating in extreme weather conditions or on rough terrain and uneven surfaces. Common applications include wheel systems for robotic forklifts, bomb disposal robots, and other robotic applications in the military and law enforcement sectors.

Urethane casting is also showing a lot of promise in soft robotics, a specific subgenre of robotics engineering that deals with constructing robots from highly compliant materials to mimic the way living organisms move and adapt to their environments.

In the early days of advanced robotics manufacturing, robots were primarily relegated to test laboratory settings. Today’s robots see a high degree of field use and are more frequently used for applications that come into close contact with humans. For example, industrial robot manufacturers in Tokyo have developed a wearable robot exosuit that contours to the wearer’s body to improve their strength, balance, and endurance. Industrial robot manufacturers are also developing robots that can safely and comfortably support the elderly or injured and help healthcare practitioners mobilize them.

Soft robotics use-cases like these wouldn’t be possible without soft gripping elements, for which urethane casting is ideal. The polyurethanes used in urethane casting are tough enough to grip hard-to-handle objects without slipping, but gentle enough to handle delicate objects like an arm in a cast. Urethane casting plays a major role in robotics used in a wide variety of real-world applications.

It’s challenging to predict exactly how the robotics sector will evolve because the possibilities are so vast and technology is advancing at an unprecedented rate. However, if industrial robot manufacturers continue to pursue soft robotics innovations designed to work alongside humans, we can expect to see more urethane casting in the robotics sector very soon. Product teams can break into this dynamic industry as soon as possible with the help of an experienced manufacturing partner.

When you partner with SyBridge to manufacture urethane casting parts, you can expect quick turnaround times, low-upfront costs, and unmatched material flexibility. All of the polyurethane materials we offer come in a variety of colors, durometers, and textures that are sure to fit your unique project requirements. If you’re looking to push the envelope and venture into advanced robotics manufacturing, we can also help you reach those goals. Contact us today to learn more about how we can turn your robotics designs into reality.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…