Previously published on fastradius.com on September 26, 2018

Nylons are a common class of plastics that have been around since the 1930s. They are a polyamide polymer traditionally used in a number of common plastic manufacturing processes for plastic films, metal coatings and tubing for oil and gas – among other things. In general, nylons are immensely popular for additive applications because of their processability, as referenced in the 2017 State of 3D Printing annual report. In general, nylons are immensely popular for additive applications because of their processability, as referenced in the 2017 State of 3D Printing annual report.

PA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. And more recently, PA 12 has been adopted as a common 3D printing material for creating functional parts and prototypes. If you’re considering converting metal parts to plastic, be sure to first evaluate the operating conditions, loading cases, acceptable creep/fatigue levels and specifications surrounding chemical and UV resistance.

It’s used in fused deposition modeling (FDM) as a filament, and in binder-jetting processes, such as HP® Multi Jet Fusion (MJF), as a powder. Proprietary forms of PA 12 have been developed for both additive technologies. HP®, for instance, created HP® 3D High Reusability PA 12 for use in its MJF process. Stratasys has deployed its own FDM filament called FDM Nylon 12™. And others are joining in as well, releasing their own proprietary PA 12 variations (such as Nylon G from MatterHackers).

Here, we’ll explain the differences between generic PA 12 / Nylon 12 used in injection molding and Stratasys’ and HP®’s proprietary PA 12 materials. Then we’ll get into the details of how PA 12 is used in FDM and MJF.

FDM Nylon 12™ comes in a spool of filament, which is heated and extruded through the printer’s nozzle during the printing process, and is specifically used in Stratasys FDM printers.

Similar to other FDM processes, supports for overhanging features need to be built into the part design. Fortunately, many FDM printers can accommodate two different extrusion heads: One for the Nylon 12 and one for the support material. The support material, such as water-soluble PVA, is designed to be easily removed after the print is complete.

Tensile strength, XYZ: 48 MPa/6960 psi

Tensile modulus, XY: 1700 MPa/247 ksi

Tensile modulus, Z: 1800 MPa/261 ksi

Elongation at break, XY: 20%

IZOD impact strength: 3.5 k J/m2

Heat Deflection (@0.45 MPa, 66 psi), XY: 175 ºC/347 ºF

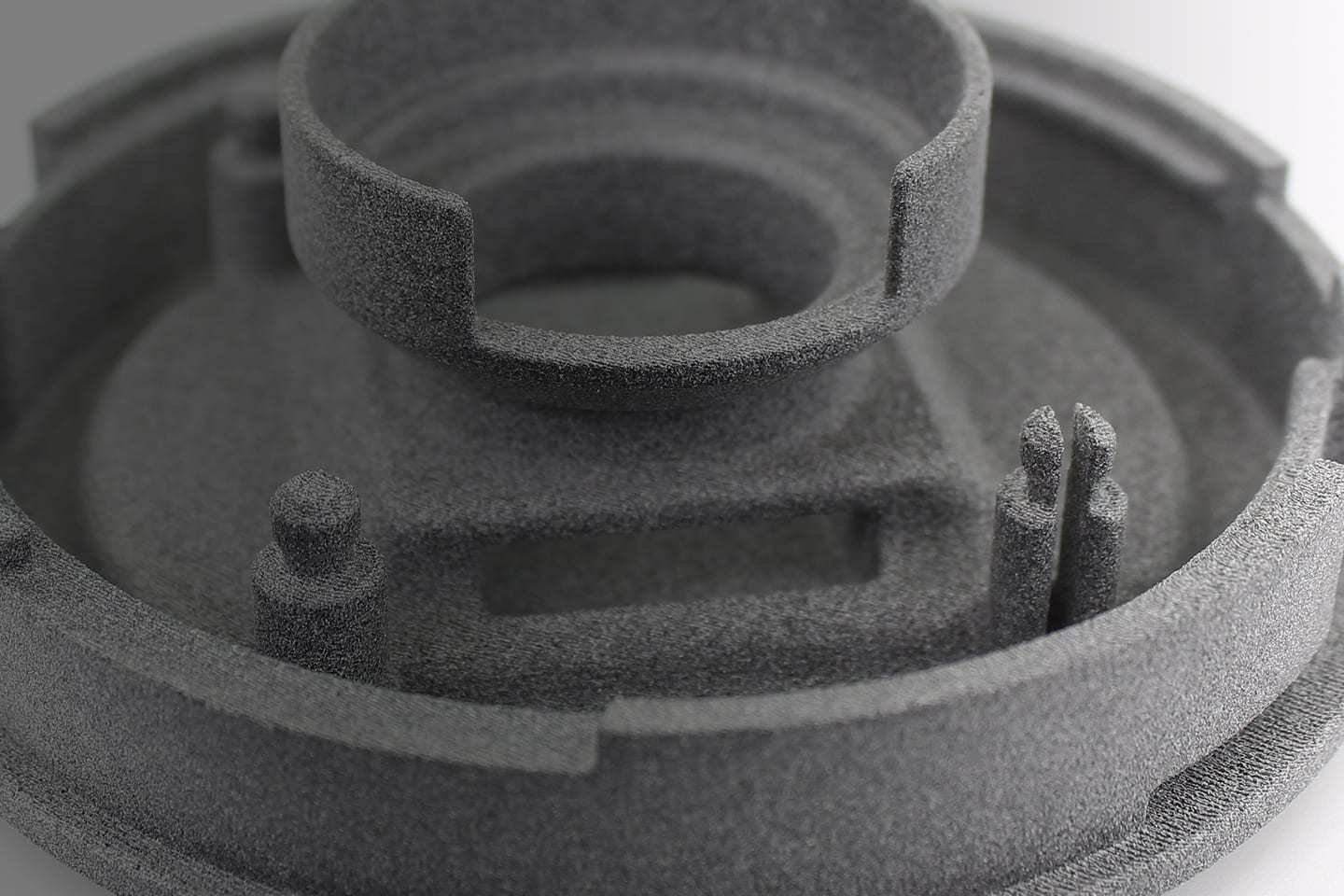

HP® 3D High Reusability Polyamide 12 (HP® PA 12) is a specific form of PA 12 designed for HP® MJF. It comes in a fine granular powder that can print parts with high resolution and fine features.

Customers often select the MJF process because of its self-supporting nature, which allows design engineers the freedom to push boundaries and print complex and intricate geometries. This also enables the ability to print assemblies in single, continuous pieces.

The large build volume of HP® MJF also allows larger parts (HP® MJF can make parts with dimensions up to 16 inches by 12 inches by 16 inches) to be manufactured. After printing, parts need to be removed from the bed of unfused powder, which requires some post-processing and should be a consideration for engineers when thinking about costs. Unlike FDM, MJF produces nearly isotropic materials with minimal stiffness difference in the printing direction.

HP® PA 12 is a great material for parts that need to balance toughness and dimensional accuracy with intricate details. SyBridge uses HP® PA 12 to print nearly isotropic parts with fine-tuned surface resolutions, higher densities and lower porosities. Texturing, coloring, embossing and engraving are also possible.

The material’s near-one-hundred-percent density means its mechanical performance emulates that of generic PA 12, which is commonly used for injection molding applications. Depending on the stringency of your material requirements, HP® PA 12 can even replace an injection molding grade of ABS.

HP® PA 12’s toughness makes it a great option for parts that require flexible materials that won’t break or crack from repeated use. Some popular applications include:

HP® PA 12’s density is similar to common plastics, such as ABS. However, the flexibility afforded by designing for additive manufacturing allows (DFAM) you to produce strong and durable parts that are lighter than traditionally-manufactured plastic components. In fact, the material’s high fatigue resistance (i.e., its ability to withstand repetitive loading cycles and vibration) makes it a great fit for parts in the aerospace and automotive industries.

HP® PA 12 is designed to minimize waste, allowing leftover powder from one build to be used in subsequent builds. This allows us to use 20% new powder and 80% recycled powder in each printing run. Recycling HP® PA 12 not only decreases material waste, but also keeps economies of scale reasonable, giving you the best material price.

HP® PA 12 isn’t restricted by too many design rules because the concerns with overhangs and taper size don’t apply. One important consideration is to design vents for internal cavities to prevent powder from being trapped.

Post-processing starts with excess powder removal. Operators will blast the final part with air or media before it can undergo surfacing finishing. HP® PA 12 comes in a standard gray color, however, if desired, customers can put their parts through a dye process to change the color to black. You can also paint parts with HP® PA 12 with any color you need.

HP® PA 12 can work within our standard lead time of five to seven business days. SyBridge can even complete a print in three business days for expedited orders or smaller builds. In general, MJF can print 251 cubic inches of a part per hour. For perspective, if an HP® print volume is completely packed, the build time could be close to 17 hours.

Post-printing cooling needs to be considered, which can take anywhere from three to 50 hours. As a general rule, smaller builds and less powder mean faster cooling periods. Fortunately, HP® has accounted for this and provides a secondary post-processing station that can rapid-cool any part in ten hours or less if needed.

If you’re interested in challenging design “rules” to create previously unmakeable products, we recommend using HP® PA 12. Contact our team to see how HP® PA 12 can bring your product vision to life.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…